News

2025-05-20

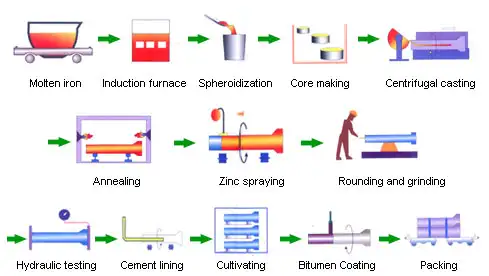

Ductile iron pipe production involves a multi-stage casting process that transforms recycled ferrous scrap into high-performance, corrosion-resistant water‐ and wastewater piping systems. A clear, standardized...

2025-05-19

Ductile iron and cast iron remain two of the most widely used ferrous materials in piping, fittings, valves and structural components. While both share a similar base chemistry, key differences in microstructure—and...

2025-05-19

Ductile iron shrinkage allowance is a critical factor in casting design, accounting for the volumetric contraction (typically 1-3%) that occurs as molten ductile iron solidifies and cools to room temperature....

2025-05-19

The history of ductile iron pipes traces back to 1948 when metallurgists at the International Nickel Company (INCO) pioneered the addition of magnesium to cast iron, creating a stronger, more flexible...

2025-05-19

Ductile iron pipe requires specialized cutting tools to ensure clean, square cuts without damaging the casting or risking operator safety. Common methods include manual rotary and hinged cutters, powerful...

2025-05-19

Ductile iron pipe coatings fall into external (asphaltic, zinc, polyethylene, epoxy) and internal linings (cement-mortar, fusion-bonded epoxy, ceramic-enhanced epoxy, glass, water-based) to protect against...

2025-05-19

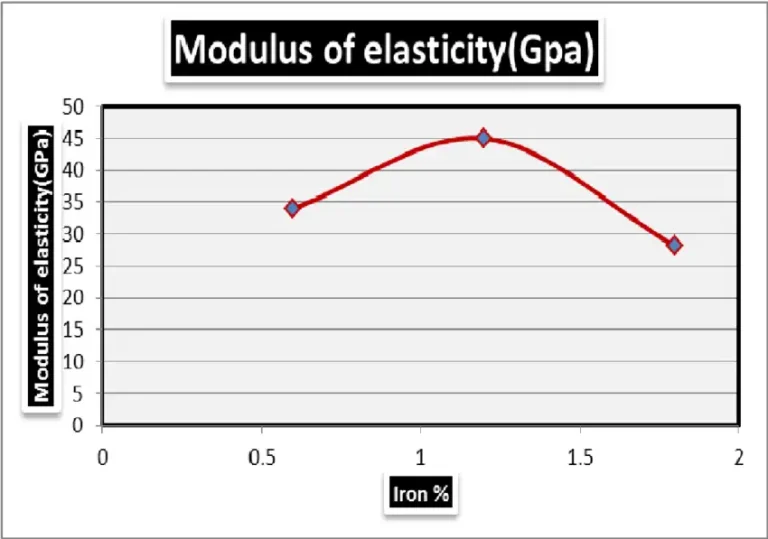

Ductile iron’s modulus of elasticity—often equated with Young’s modulus—quantifies its stiffness under elastic loading and is critical to predicting deflection, vibration, and stress in engineering designs....

2025-05-19

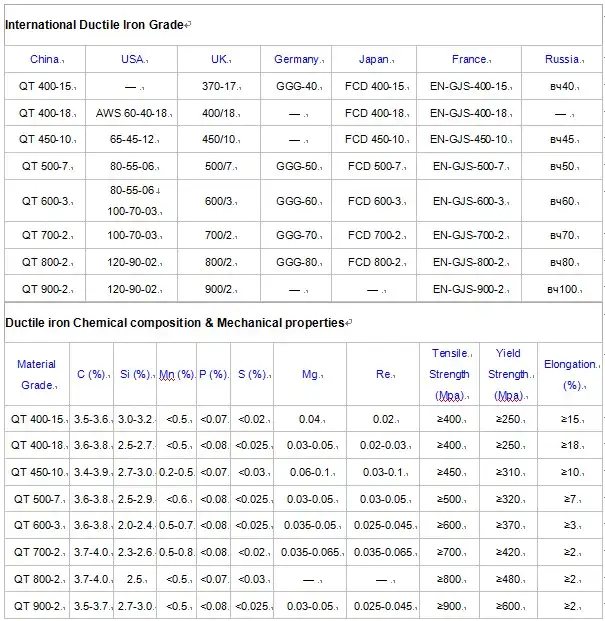

Ductile iron material grades are critical classifications that define the mechanical properties, performance, and applications of this versatile cast iron alloy. Also known as nodular or spheroidal graphite...

2025-05-16

Ductile iron flanged spools are prefabricated lengths of ductile iron pipe with one or two integrally cast flanged ends. They provide flexibility during installation—allowing easy mating to valves, fittings,...

2025-05-16

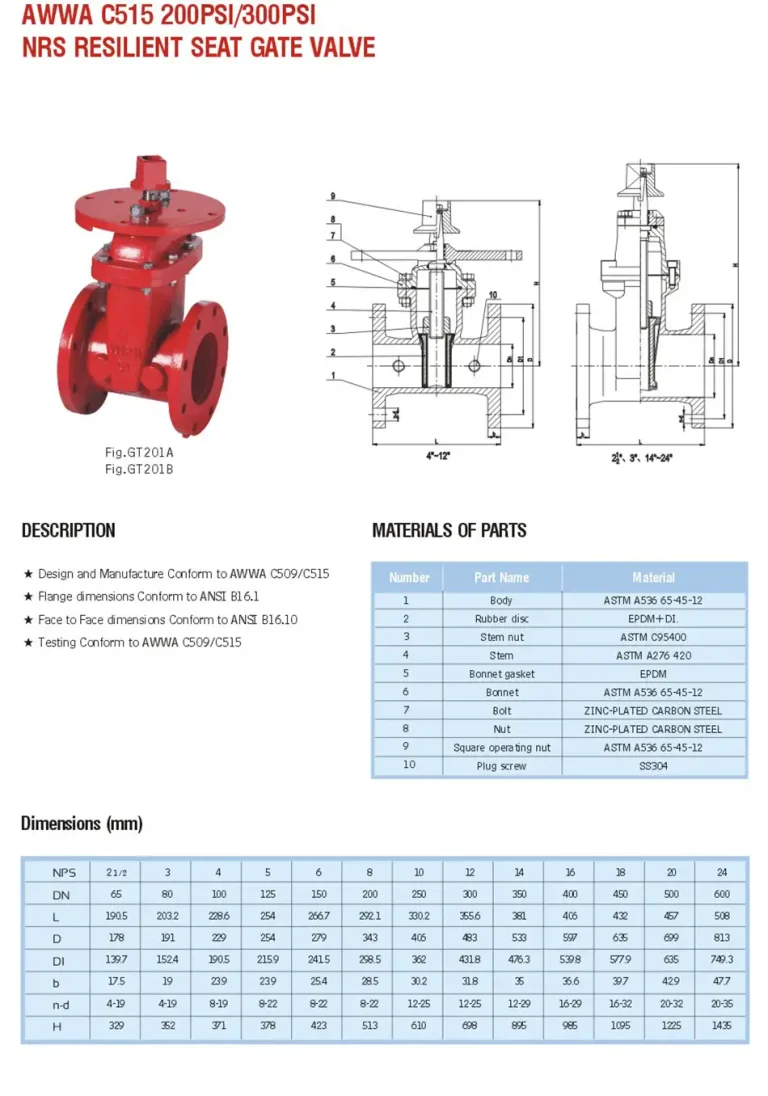

This comprehensive guide covers ductile iron flanged AWWA C515 gate valves in depth, fulfilling needs from material standards to installation best practices. In nine detailed sections, you’ll learn about...

2025-05-16

Ductile iron flanged fittings are critical components in high-pressure piping systems—widely used in water, wastewater, fire protection, and industrial applications. Ductile Iron Flanged Fittings Dimensions...

2025-05-16

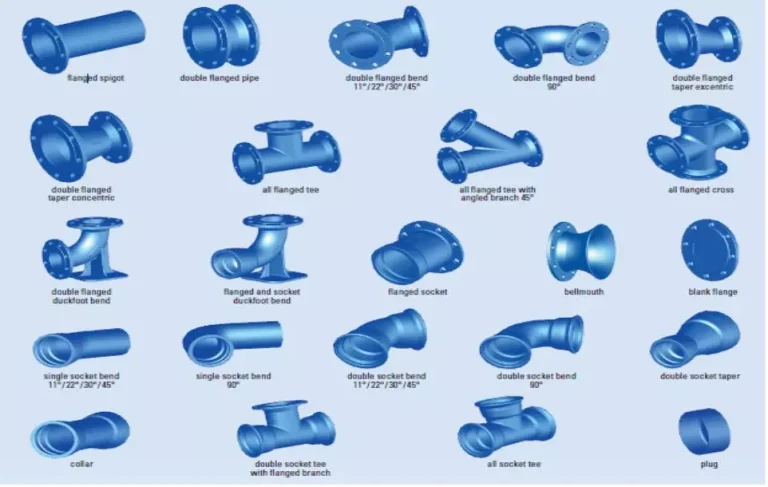

Welcome to our comprehensive Ductile Iron Fittings Catalogue, your ultimate resource for high-quality, durable piping solutions. Designed for industrial, municipal, and construction applications, our ductile...

No posts found