News

2025-04-28

Improving elongation in ductile iron requires optimizing its microstructure to enhance ductility while maintaining strength. Key approaches include controlling nodule count (aiming for 100-150 nodules/mm²),...

2025-04-28

Enhancing the fluidity of ductile iron is crucial for achieving defect-free castings with complex geometries. Key strategies include optimizing pouring temperature (typically 1350-1420°C), adjusting carbon...

2025-04-28

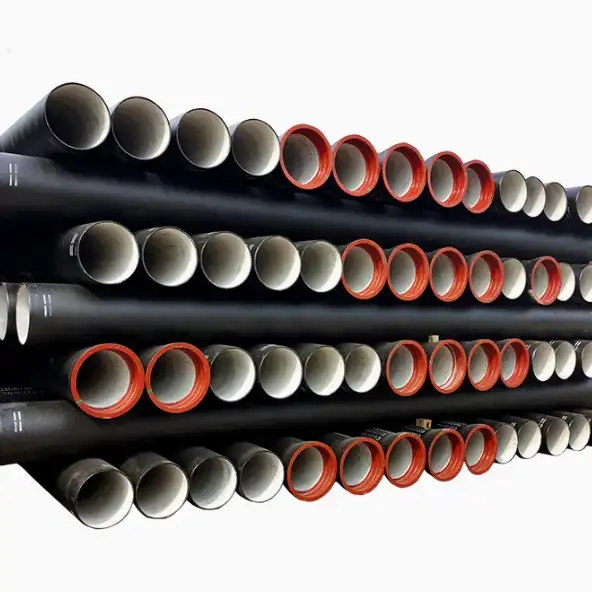

Hydrotesting ductile iron pipe is a critical quality control process that verifies system integrity by pressurizing the pipeline with water to detect leaks or weaknesses. Conducted after installation,...

2025-04-28

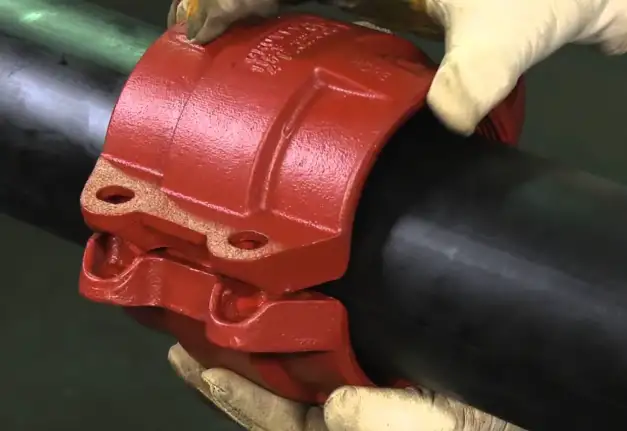

Grooving ductile iron pipe involves machining precise circumferential grooves near pipe ends to accommodate mechanical couplings, enabling fast and secure connections without welding or threading. This...

2025-04-28

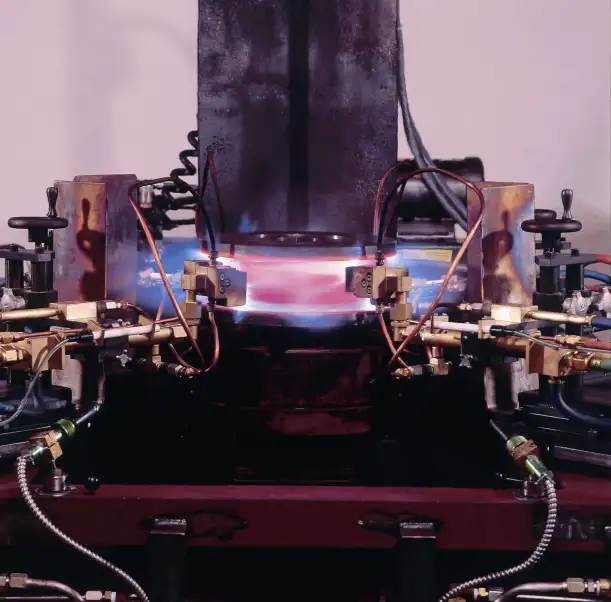

Flame hardening ductile iron is a localized heat-treating process that enhances surface hardness and wear resistance while maintaining the material’s core toughness. This controlled technique involves...

2025-04-28

Installing ductile iron pipe requires proper alignment, joint assembly, and sealing techniques to ensure a leak-free, durable connection. Common methods include push-on rubber gasket joints, mechanical...

2025-04-28

A ductile iron tee is a T-shaped pipe fitting made from ductile iron, a high-strength, corrosion-resistant material with enhanced flexibility compared to traditional cast iron. Designed to split or combine...

2025-04-28

Cutting large ductile iron pipe demands robust tools and precise techniques to maintain structural integrity and safety. Common methods include using diamond-blade saws, oxy-acetylene torches, or hydraulic...

2025-04-28

Connecting ductile iron to stainless steel requires careful consideration of material compatibility, joint integrity, and corrosion prevention. Common transition methods include flanged connections with...

2025-04-28

Creating a precise tapered recess in ductile iron castings requires specialized machining techniques to maintain dimensional accuracy and surface finish. Common methods include using tapered end mills,...

2025-04-28

Identifying the differences between cast iron and ductile iron involves examining physical properties, microstructure, and performance characteristics. While both are iron-based alloys, ductile iron’s...

2025-04-28

Cutting cement-lined ductile iron pipe requires specialized tools and techniques to maintain the integrity of both the iron pipe and its protective lining. Common methods include abrasive saws, diamond-blade...

No posts found