News

2025-04-30

Ductile iron pipes are widely used in water distribution systems due to their strength, durability, and resistance to corrosion. The price of a 4-inch ductile iron pipe varies based on several factors,...

2025-04-30

Graphite cast iron, a versatile material in the family of cast irons, is distinguished by its unique graphite microstructure. This structure imparts a combination of strength, thermal conductivity, and...

2025-04-30

ASTM A536 Grade 70-50-05 ductile iron has direct equivalents in several international standards, offering similar 70 ksi tensile strength, 50 ksi yield strength, and 5% elongation. Key equivalents include:...

2025-04-30

ASTM A536 Grade 65-45-12 ductile iron typically undergoes annealing heat treatment to achieve its optimal balance of strength and ductility. This process involves heating the iron to 1,650–1,750°F (900–955°C),...

2025-04-30

The designation 65-45-12 for ductile iron refers to its minimum material properties as defined by ASTM A536 standards. These numbers indicate: 65 ksi (450 MPa) tensile strength – High resistance to breaking...

2025-04-30

Wrapping ductile iron pipe is a critical protective measure to prevent corrosion and extend its service life, especially in aggressive soil or high-moisture environments. Common protective wrapping methods include polyethylene...

2025-04-30

Properly restraining a mechanical joint on ductile iron pipe is essential to prevent separation from thrust forces in pressurized systems. Common restraint methods include mega-lug restraints, tie rods,...

2025-04-30

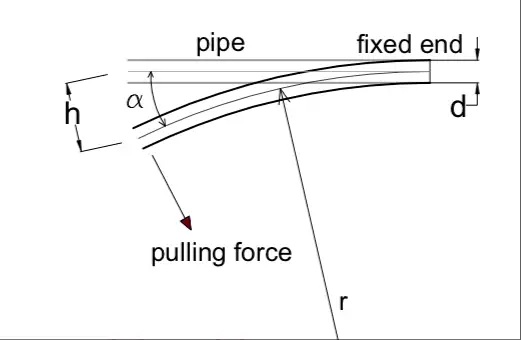

The allowable deflection in ductile iron pipe refers to the maximum safe angular movement permitted at pipe joints to accommodate ground shifts, thermal changes, and installation curves. According to AWWA...

2025-04-30

Ductile iron pipe joint deflection refers to the controlled angular movement allowed at pipe joints to accommodate terrain changes, thermal expansion, and ground settlement. Engineered for durability, push-on...

2025-04-30

Connecting PVC pipe to cast iron pipe requires the right fittings and techniques to ensure a secure, leak-proof seal. Common methods include using a rubber transition coupling (Fernco coupling), a hub-and-spigot...

No posts found