Welcome to our comprehensive Ductile Iron Fittings Catalogue, your ultimate resource for high-quality, durable piping solutions. Designed for industrial, municipal, and construction applications, our ductile iron fittings offer superior strength, corrosion resistance, and longevity. This catalogue features a wide range of products, including elbows, tees, couplings, and flanges, all manufactured to meet international standards like ISO 2531 and EN 545.

1. Introduction to Ductile Iron Fittings

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, revolutionized piping systems with its superior mechanical performance compared to gray iron. Discovered in the 1940s, ductile iron achieves its unique combination of high tensile strength, excellent impact resistance, and good fatigue properties through nodular graphite inclusions formed during controlled nodulizing treatments. As a result, ductile iron is the material of choice for municipal water and wastewater pipelines, irrigation systems, and industrial fluid transport. Fittings—such as bends, tees, reducers, and couplings—play a critical role in directing flow, accommodating changes in diameter, and connecting pipes of various types (flanged, push-on, mechanical joint). Modern ductile iron fittings must conform to stringent international standards (e.g., ISO, EN, AWWA) to ensure leak-free performance under high pressures and corrosive environments.

2. Material Standards and Certifications

Compliance with recognized standards ensures the reliability and interchangeability of ductile iron fittings worldwide.

-

ISO 2531 & ISO 7186

Define requirements for ductile iron pipes and fittings, including mechanical properties, hydrostatic testing, and dimensional tolerances. -

EN 545 & EN 598

European standards specifying ductile iron fittings for water supply and wastewater applications, with detailed pressure class designations (e.g., PN10, PN16). -

AWWA C110/C153

American Water Works Association standards covering both standard weight (C110) and compact fittings (C153), including flange drilling, coating, and joint restraints. -

ASTM A536

Describes the chemical composition and mechanical properties of ductile iron castings used to produce fittings. -

NSF/ANSI 61

Certifies that the internal linings (e.g., cement mortar, epoxy) meet potable water requirements.

Modern manufacturers often carry dual certifications (e.g., EN & AWWA) to serve global markets. Third-party testing by bodies such as DVGW (Germany), WRAS (UK), and KIWA (Netherlands) further validates compliance and performance.

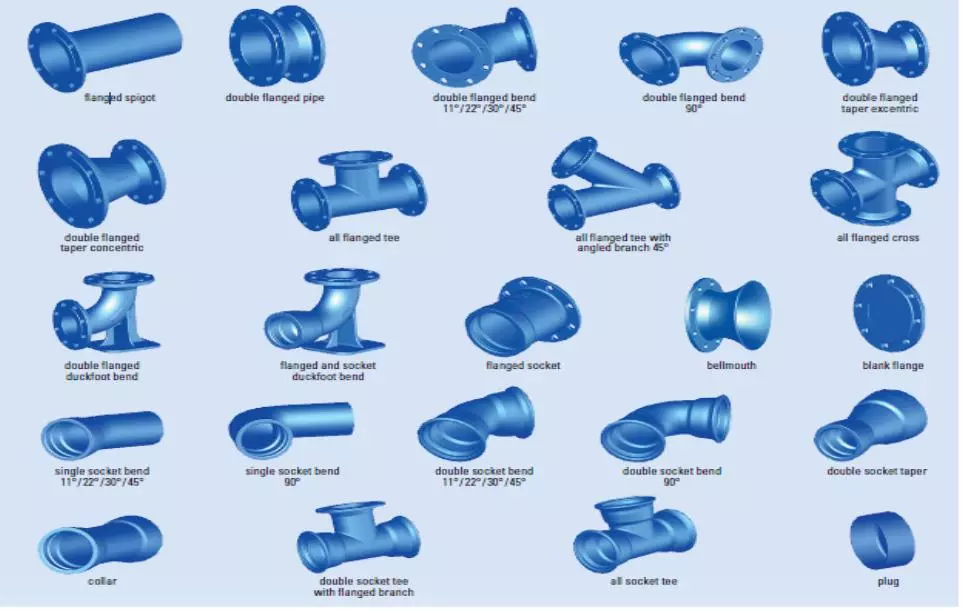

3. Types of Ductile Iron Fittings

Below are the nine most commonly used ductile iron fitting categories, each described in detail:

3.1 Bends & Elbows

Bends (or elbows) change pipe direction in 90° or 45° increments. They are available in short-radius (1D) and long-radius (1.5D) configurations.

-

Short-radius: Compact footprint; higher pressure loss.

-

Long-radius: Reduced turbulence; lower head loss.

3.2 Tees & Lateral Tees

Tees allow branch connections at 90°; lateral tees offer a 45° branch angle for smoother flow. Pressure distribution and wall thickness differ between run and branch outlets to accommodate hydraulic stresses.

3.3 Reducers

Concentric and eccentric reducers transition between different pipe diameters.

-

Concentric: Symmetrical, suitable for vertical pipelines.

-

Eccentric: Flat on one side, prevents air pockets in horizontal runs.

3.4 Crosses

Cross fittings enable flow in four directions. Due to stress concentrations, they are reserved for low-pressure, non-critical services.

3.5 Caps & Plugs

Used to close off pipe ends. Caps slip over the pipe OD; plugs insert into the pipe ID. Ideal for system flushing or future expansion.

3.6 Couplings & Mechanical Joints

-

Push-On Couplings: Snap-on rubber gasket, quick assembly.

-

Mechanical Joint (MJ): Bolted gland-and-gasket assembly, adjustable, allows angular deflection.

3.7 Flanged Fittings

Flanged ends conform to ANSI/AWWA drilling patterns. Available in lap-joint, swivel-joint, and integral flange styles. Simplify alignment during installation.

3.8 Tapping Tees & Saddles

Permit service connections under pressure. Tapping tees include an integrated valve; saddles clamp onto existing mains—ideal for retrofits.

3.9 Special Fittings

Include custom manifolds, pipe caps with test ports, and restraint devices (e.g., wedge action restraints, restraining rods) to prevent joint separation under thrust forces.

4. Dimensions & Specifications

All fittings follow standardized dimension tables to ensure interchangeability:

| Fitting Type | Standard | Nominal Size Range (mm/in) | Pressure Class | End Connection |

|---|---|---|---|---|

| Bend 90° | EN 598 | 80–1,200 mm (3″–48″) | PN10/PN16 | Push-On, Flange |

| Tee | AWWA C110 | 3″–24″ | Class 150 psi | Mechanical Joint |

| Reducer | ISO 7186 | 50–600 mm | PN10–PN25 | Bolt Flange |

| Flanged End | AWWA C153 | 3″–12″ | Class 350 psi | Integral Flange |

Table 1: Comparative Specifications of Common Ductile Iron Fittings

5. Connection & Jointing Methods

5.1 Push-On Joints

Rubber-gasket seal over the pipe spigot; no bolts required. Quick and cost-effective for medium-pressure systems.

5.2 Mechanical Joint (MJ)

Gland, gasket, bolts, and nuts clamp the pipe spigot into the fitting. Allows ±4° deflection per joint and accommodates settlement.

5.3 Flanged Joints

Bolted flange faces with gaskets. Offers maximum alignment control and easy disassembly—common in valves and pumps.

5.4 Restrained Joints

Incorporate devices (e.g., wedges, rods) to lock the spigot and socket, preventing separation under surge or thrust loads.

6. Manufacturing Processes & Coatings

6.1 Casting & Machining

Melting pig iron, ductile-promoting nodulizers (e.g., magnesium), and inoculants; sand casting in green or resin-bonded molds. Post-cast heat treatment and precision CNC machining ensure dimensional accuracy.

6.2 Internal Lining

-

Cement Mortar: AWWA C104; 2½ mm thickness by spin-lining; resistant to corrosion, roughness coefficient (C-factor) ~120.

-

Epoxy: Typically 250–500 μm; smooth surface; approved for potable water to NSF/ANSI-61.

6.3 External Coating

-

Bituminous Asphalt: Primers and finish coats for corrosion protection.

-

Polyurethane: Durable, UV-resistant finish for exposed pipelines.

7. Installation & Maintenance Best Practices

-

Handling: Use slings/choker chains; avoid metal-to-metal contact on lining or coatings.

-

Alignment: Ensure proper bar-in depth for push-on joints; use lubrication on gaskets.

-

Trenching: Follow bedding standards (e.g., pea gravel, sand) to prevent point loading.

-

Hydrostatic Testing: Pressure-test the assembled pipeline at 1.5× design pressure.

-

Periodic Inspection: Monitor external coating condition, check bolts/glands for tightness, flush systems to remove sediment.

8. Quality Testing & Traceability

Each fitting batch undergoes:

-

Tensile, Hardness & Impact Tests per ASTM A536.

-

Dimensional Checks on key physical features.

-

Hydrostatic Pressure Tests at 1.5× rated pressure.

-

Non-Destructive Testing (NDT): Ultrasonic, magnetic particle for detecting internal flaws.

Traceability is maintained via cast-in heat numbers, barcodes, and detailed mill certificates.

9. Applications & Selection Guide

9.1 Municipal Water Distribution

Choose PN16 push-on bends and tees with cement-mortar lining for durability and low maintenance.

9.2 Sewer & Wastewater

Opt for epoxy-lined fittings rated PN10; corrosion protection against aggressive effluents.

9.3 Industrial Process Piping

Select Class 350 psi flanged fittings with polyurethane finish and mechanical joints for chemical resistance and frequent isolation.

9.4 Fire Protection

Use high-pressure flanged fittings (Class 350 psi) with NSF/ANSI 61-approved epoxy lining to ensure reliability under surge conditions.

Embedded Video Tutorial

6 Common Questions & Answers

Q1: What determines the pressure rating of a ductile iron fitting?

The pressure rating depends on the fitting’s design class (e.g., PN10, PN16, Class 150 psi, Class 350 psi), which is set by its minimum wall thickness, the material’s tensile strength (≥ 483 MPa per ASTM A536 Grade 65-45-12), and the safety factor specified in standards such as ISO 2531 or AWWA C110. Short-radius bends typically have the same rating as straight pipes of equivalent nominal thickness, but pressure drop may be greater. Flanged fittings rely on flange drilling and bolt size to maintain the rating under internal pressure and external thrust loads. All fittings must be hydrostatically tested at 1.5× the marked rating to verify performance before shipment.

Q2: How do I choose between cement mortar and epoxy lining for potable water fittings?

Cement mortar lining—installed by spin-lining AWWA C104 mortar—is well-proven, cost-effective, and provides a roughness coefficient of C≈120 for stable flow calculations. However, it may be unsuitable for aggressive waters with pH < 6.5 or high sulfate content due to leaching risk, and it can be brittle under thermal cycling. Epoxy linings (typically 250–500 μm thick) offer a smoother surface (C≈140), superior chemical resistance, and strip-coating uniformity but at higher cost and with potential curing variability. Consider water chemistry, operating temperature, and lifecycle cost; confirm NSF/ANSI 61 certification for potable applications.

Q3: Can push-on and mechanical joint fittings be used interchangeably?

While both joint types accommodate deflection (push-on ±5°, MJ ±4° per joint), they differ in assembly and sealing mechanisms. Push-on joints use an elastomeric gasket held by spigot-socket compression—ideal for rapid installation in straight runs. Mechanical joints use a gland, gasket, and bolts, permitting field tightening and re-adjustment under settlement. Mechanical joints provide slightly higher confinement against thrust forces. They are not interchangeable on the same fitting without matching the end preparation and joint spec; always select the fitting style specified in the piping design drawings.

Q4: What are the most common failure modes of ductile iron fittings in service?

Corrosion—both external (soil, stray current) and internal (microbial influenced corrosion, acidic water)—is the leading cause. Proper external coating and cathodic protection mitigate soil side corrosion; internal linings and water chemistry control prevent internal attack. Mechanical stress concentration at short-radius bends and tees can lead to fatigue cracking under cyclic pressure. Improper joint assembly (inadequate gasket lubrication, under-torqued bolts) may result in leaks or joint separation under surge. Finally, abrasion by entrained solids can erode internal surfaces; consider abrasion-resistant linings in such services.

Q5: How should I specify ductile iron fittings for seismic zones?

In seismically active areas, joint flexibility and restraint are critical. Use mechanical joints or restrained push-on joints with integral locking devices (e.g., Tyton® R-joint with locking ring) to allow pipe movement without separation. Limit rigid flanged connections to anchors and major equipment; minimize unrestrained angles. Confirm compliance with local seismic codes (e.g., AWWA M11, AWWA C600), and coordinate with structural engineers on thrust block design and joint restraint placement. Provide allowances for ±0.5 in. axial movement per 100 ft of pipeline.

Q6: What maintenance practices extend the service life of ductile iron fittings?

Implement regular external inspections—clean and recoat any coating defects; monitor stray current and adjust cathodic protection. Internally, perform periodic flushing to remove sediment and microbiological growth; inspect water pH and adjust treatment to maintain a neutral range (6.8–8.5). Tighten mechanical joint bolts after the first 12 months to compensate for gasket relaxation. Schedule ultrasonic wall-thickness measurements at 10 year intervals for high-risk services. Keep a detailed record of installation dates, test pressures, and maintenance activities for traceability and lifecycle analysis.

References:

- ISO 2531: Ductile iron pipes, fittings, accessories and their joints for water applications — Requirements and test methods | ISO Official Site

- EN 545: Ductile iron pipes, fittings, accessories and their joints for water pipelines — Requirements and tests | CEN Standards

- AWWA C110: Ductile-Iron and Gray-Iron Fittings | American Water Works Association

- ASTM A536: Standard Specification for Ductile Iron Castings | ASTM International

- NSF/ANSI 61: Drinking Water System Components – Health Effects | NSF International