News

2025-04-29

Welding ductile iron to stainless steel presents unique challenges due to differences in thermal expansion, carbon content, and metallurgical properties. To achieve a strong, crack-free joint, proper techniques...

2025-04-29

Welding ductile iron castings requires specialized techniques to overcome challenges like cracking, porosity, and residual stresses. Unlike other metals, ductile iron’s unique graphite structure...

2025-04-29

Threading ductile iron pipes is a critical process in plumbing, construction, and industrial applications. Proper threading ensures secure connections, prevents leaks, and maintains the integrity of the...

2025-04-28

Welding an anode to ductile iron pipe requires specialized techniques to ensure a durable electrical connection for effective corrosion prevention. The process involves surface preparation, preheating...

2025-04-28

Identifying ductile iron versus steel requires analyzing material properties, surface characteristics, and performance under stress. While both are iron-based, ductile iron’s graphite nodules (visible...

2025-04-28

Tapping ductile iron pipe requires specialized tools and techniques to create a secure branch connection without compromising the pipe’s integrity. Common methods include pressure-tapping with split-sleeve...

2025-04-28

Repairing a hole in ductile iron pipe requires assessing the damage size and selecting an appropriate method—such as epoxy putty for small pinholes, full-circle clamps for moderate damage, or welded/sleeve...

2025-04-28

Installing Class 52 ductile iron pipe requires proper handling and joint techniques to meet its high-pressure rating (350 psi). The assembly process involves precise alignment of push-on or mechanical...

2025-04-28

Proper installation of ductile iron pipe requires careful trench preparation, joint assembly, and backfilling techniques to ensure long-term performance. Key steps include bedding the pipe on compacted...

2025-04-28

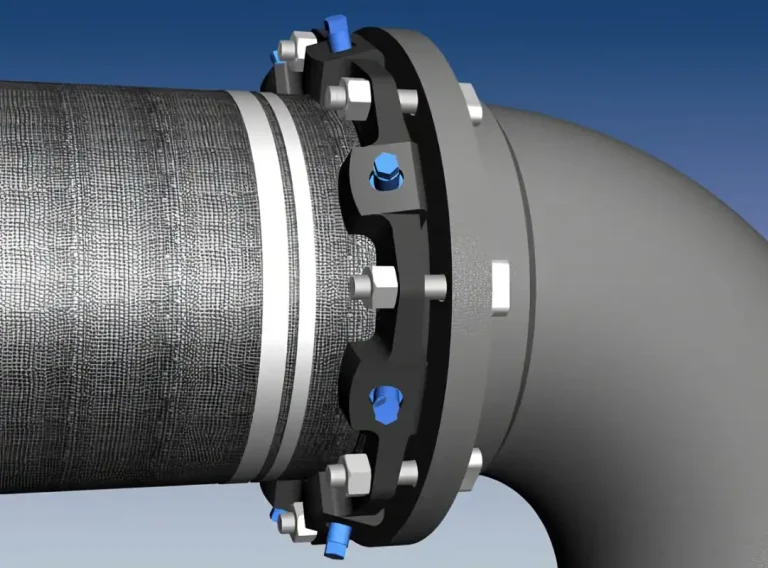

Joining mechanical joints (MJ) on ductile iron pipe requires proper alignment, gasket seating, and bolt tightening to ensure a leak-proof, durable connection. This AWWA C111-compliant method involves assembling...

No posts found