Ductile iron material grades are critical classifications that define the mechanical properties, performance, and applications of this versatile cast iron alloy. Also known as nodular or spheroidal graphite iron, ductile iron offers exceptional strength, durability, and machinability, making it a preferred choice in industries like automotive, construction, and piping systems. Key grades—such as ASTM A536 (60-40-18, 65-45-12, 80-55-06) and EN-GJS-400-15—vary in tensile strength, yield strength, and elongation to meet specific engineering demands.

1. Understanding Ductile Iron Grades

Ductile iron grades are usually categorized based on tensile strength, yield strength, and elongation. These values are dependent on composition, microstructure, and heat treatment.

Common Ductile Iron Grades:

| Grade (ASTM) | Minimum Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 60-40-18 | 414 | 276 | 18 |

| 65-45-12 | 448 | 310 | 12 |

| 70-50-05 | 483 | 345 | 5 |

| 80-55-06 | 552 | 379 | 6 |

| 100-70-03 | 689 | 483 | 3 |

2. ASTM Standards for Ductile Iron

The American Society for Testing and Materials (ASTM) classifies ductile iron under several standards, primarily in the ASTM A536 specification. Here’s a breakdown:

ASTM A536 Grades:

| ASTM Grade | Description | Common Applications |

|---|---|---|

| 60-40-18 | High elongation, low strength | Automotive parts, pump housings |

| 65-45-12 | Balanced strength and ductility | Valves, gears, pipe fittings |

| 70-50-05 | Medium strength and low ductility | Pressure pipes, shafts |

| 80-55-06 | High strength, moderate ductility | Gear boxes, crankshafts |

| 100-70-03 | Very high strength, low ductility | Structural components, machinery |

3. ISO and EN Standards for Ductile Iron

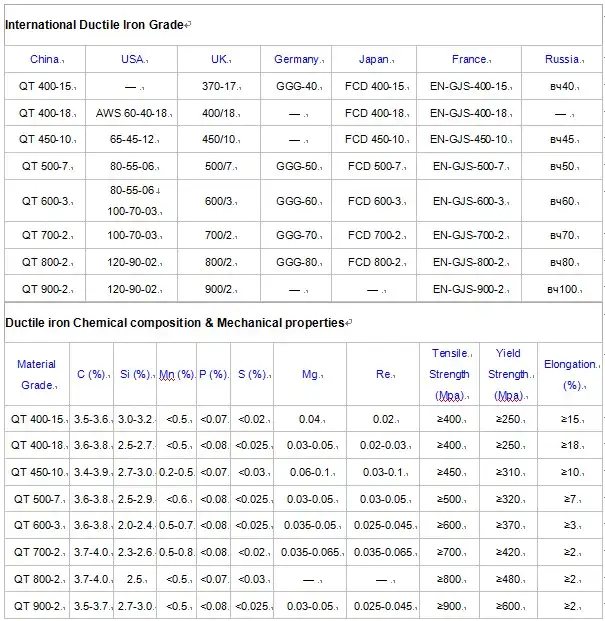

Globally, ductile iron is also classified by ISO 1083 and EN 1563 standards. These standards provide different naming systems but similar mechanical property ranges.

ISO 1083 Grades:

| ISO Grade | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| GJS-400-15 | 400 | 15 |

| GJS-500-7 | 500 | 7 |

| GJS-600-3 | 600 | 3 |

| GJS-700-2 | 700 | 2 |

These grades are similar to ASTM grades in terms of mechanical performance.

4. Chemical Composition of Ductile Iron Grades

The chemical composition affects graphite morphology and mechanical performance.

Typical Chemical Range:

| Element | Range (%) | Purpose |

|---|---|---|

| Carbon | 3.5 – 4.0 | Promotes graphite formation |

| Silicon | 2.2 – 2.8 | Strengthens matrix, stabilizes graphite |

| Manganese | <0.5 | Increases hardness |

| Magnesium | 0.03 – 0.06 | Nodule formation |

| Phosphorus | <0.05 | Should be minimized |

| Sulfur | <0.02 | Should be minimized |

5. Mechanical Properties of Ductile Iron Grades

Ductile iron’s mechanical properties vary based on grade and heat treatment. Properties include:

-

Tensile strength: up to 900 MPa

-

Yield strength: up to 700 MPa

-

Elongation: up to 18%

-

Hardness: from 150 HB to 300 HB

-

Impact resistance: high, even at low temperatures

Property Comparison Table:

| Grade | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| 60-40-18 | 414 | 276 | 18 | 130–180 |

| 100-70-03 | 689 | 483 | 3 | 240–300 |

6. Applications of Different Ductile Iron Grades

Each ductile iron grade suits specific applications depending on required properties.

| Grade | Key Applications |

|---|---|

| 60-40-18 | Brake drums, pump casings, suspension parts |

| 65-45-12 | Manhole covers, flanges, pipe fittings |

| 80-55-06 | Crankshafts, compressors, gear boxes |

| 100-70-03 | Wind turbine hubs, machine bases, industrial shafts |

7. Comparison Table of Common Ductile Iron Grades

| Property | ASTM 60-40-18 | ASTM 65-45-12 | ASTM 80-55-06 | ASTM 100-70-03 |

|---|---|---|---|---|

| Tensile (MPa) | 414 | 448 | 552 | 689 |

| Yield (MPa) | 276 | 310 | 379 | 483 |

| Elongation (%) | 18 | 12 | 6 | 3 |

| Ductility | Excellent | Good | Fair | Low |

| Strength | Low | Moderate | High | Very High |

8. Heat Treatment and Microstructure

Heat treatment can modify the microstructure of ductile iron to enhance strength or ductility.

Types of Heat Treatment:

-

Annealing: Improves ductility by spheroidizing pearlite into ferrite.

-

Normalizing: Refines the microstructure to increase toughness.

-

Tempering: Reduces brittleness after hardening.

-

Austempering: Produces ADI (Austempered Ductile Iron) with high strength and wear resistance.

Microstructure Types:

-

Ferritic Ductile Iron: High elongation, lower strength

-

Pearlitic Ductile Iron: Higher strength, lower ductility

-

Martensitic/Austempered Ductile Iron: Extreme strength and wear resistance.

FAQ – Ductile Iron Grades

1. What is the difference between ASTM 60-40-18 and ASTM 100-70-03 ductile iron?

ASTM 60-40-18 offers higher ductility with 18% elongation, but lower strength (414 MPa tensile), making it ideal for applications needing flexibility. On the other hand, ASTM 100-70-03 provides very high tensile strength (689 MPa) and low elongation (3%), making it suitable for structural applications where strength is crucial. The trade-off between strength and ductility is the main difference.

2. How does heat treatment affect ductile iron grades?

Heat treatment can modify the matrix structure of ductile iron. For instance:

-

Annealed ductile iron becomes ferritic, increasing elongation.

-

Normalized ductile iron increases toughness and strength.

-

Austempering creates ADI (Austempered Ductile Iron), dramatically increasing hardness and fatigue resistance, useful for gears and wear-resistant parts. Each treatment tailors the iron for specific performance requirements.

3. What are the international equivalents of ASTM ductile iron grades?

ASTM grades such as 60-40-18 are approximately equivalent to ISO GJS-400-15 and EN-GJS-400-15 in ISO and EN standards. While the values are similar, it’s essential to match not just tensile strength, but also yield strength and elongation when comparing internationally. Each standard has slightly different testing and naming conventions.

4. Why is ductile iron preferred over gray iron in many applications?

Ductile iron has superior mechanical properties due to its nodular graphite, offering:

-

Higher tensile strength

-

Greater elongation

-

Better impact resistance

-

Improved machinability

This makes it suitable for structural and load-bearing parts where gray iron would be too brittle.

5. What factors affect the grade selection of ductile iron?

Grade selection depends on:

-

Required mechanical properties (strength vs. ductility)

-

Service conditions (temperature, load, impact)

-

Machinability and casting complexity

-

Cost considerations

For example, pipe manufacturers may prefer GJS-500-7 for strength and corrosion resistance, while automotive parts often use 60-40-18 for ductility.

6. Can ductile iron be welded?

Yes, ductile iron can be welded, but it requires special techniques:

-

Preheating to 300°C or more to avoid thermal shock

-

Nickel-based electrodes to maintain ductility

-

Slow cooling to prevent cracking

Improper welding can lead to microstructural degradation, so it’s mostly avoided unless necessary. Mechanical fastening or casting integration is usually preferred.