Grooving ductile iron pipe involves machining precise circumferential grooves near pipe ends to accommodate mechanical couplings, enabling fast and secure connections without welding or threading. This process requires specialized grooving tools (roll groovers or cut groovers) that maintain the pipe’s structural integrity while achieving ANSI/AWWA-compliant groove dimensions.

1. Introduction to Grooved Ductile Iron Pipe

Ductile iron pipes are widely used in water and sewage systems due to their strength, durability, and resistance to corrosion. Grooving, or the process of creating a groove on the pipe’s surface, is essential for connecting the pipes securely without the need for welding or threading.

In this comprehensive guide, we will explore everything about grooving ductile iron pipes—from the tools and techniques to the benefits and challenges. Whether you’re an experienced professional or a newcomer, this guide will help you understand the complete grooving process and how it can benefit your projects.

2. What is a Grooved Ductile Iron Pipe?

2.1. Definition and Purpose

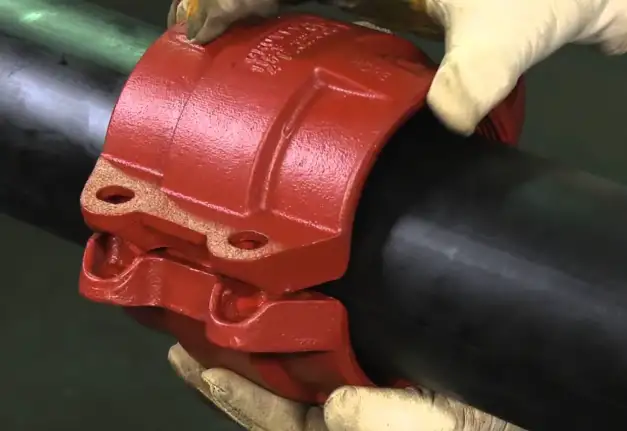

A grooved ductile iron pipe is a type of pipe that features a specially designed groove along its surface. This groove allows for the attachment of fittings and other components through the use of a groove coupling system. It eliminates the need for traditional pipe joining methods like welding or threading, making installation easier and faster.

2.2. Common Applications of Grooved Ductile Iron Pipes

Grooved ductile iron pipes are commonly used in the following applications:

-

Water distribution systems

-

Fire protection systems

-

Wastewater systems

-

HVAC systems

-

Industrial piping systems

The grooved design helps improve installation time and provides a more flexible and secure connection method.

3. Why Grooved Ductile Iron Pipe?

3.1. Advantages of Grooving Ductile Iron Pipe

-

Ease of Installation: Grooved joints require no welding or threading, making them faster and easier to install.

-

Flexibility: The grooved connection system allows for some flexibility and movement, which is especially beneficial in earthquake-prone areas or locations with ground movement.

-

Corrosion Resistance: Ductile iron pipes themselves are highly resistant to corrosion, and the grooved design does not compromise this feature.

-

Cost-Effective: The elimination of welding and threading reduces labor and material costs, making it a cost-effective solution for large projects.

3.2. Comparing Grooved to Threaded or Welded Pipe Joints

| Feature | Grooved Joints | Threaded Joints | Welded Joints |

|---|---|---|---|

| Installation Time | Fast | Moderate | Slow |

| Cost | Lower | Higher | Higher |

| Flexibility | High | Low | Low |

| Maintenance | Easy to replace or repair | Difficult to replace | Difficult to repair |

| Corrosion Resistance | Excellent | Good | Excellent |

4. How to Groove Ductile Iron Pipe

4.1. Understanding the Grooving Process

Grooving is done by creating a ring-shaped groove around the pipe’s circumference. This process ensures that the grooved section will fit securely with the grooved couplings.

The general steps in grooving ductile iron pipes are:

-

Preparation: Clean the surface of the pipe to remove any dirt, oil, or rust.

-

Measuring and Marking: Accurately measure and mark the section of the pipe that needs to be grooved.

-

Grooving: Use a specialized grooving machine to cut the groove into the pipe.

-

Inspection: Ensure that the groove dimensions are correct and the surface is smooth and free of defects.

4.2. Tools and Equipment Used for Grooving

To groove ductile iron pipes, the following tools and equipment are commonly used:

-

Grooving Machine: A mechanical device designed specifically to cut grooves in ductile iron pipes. There are different types of machines, including manual and automated ones.

-

Pipe Clamps: Used to secure the pipe in place during the grooving process.

-

Cutting Tool: The cutting tool inside the grooving machine performs the actual grooving.

-

Measuring Tools: To ensure the correct groove size, measuring tools like calipers and rulers are necessary.

4.3. Types of Grooves

There are different types of grooves used for ductile iron pipes:

-

Standard Groove: Typically used for regular pipe sizes and installation.

-

Flanged Groove: Includes a flange for a more secure connection.

-

Victaulic Groove: Specifically designed for Victaulic coupling systems.

4.4. Step-by-Step Grooving Instructions

Step 1: Secure the Pipe

-

Clamp the ductile iron pipe into the grooving machine using pipe clamps to ensure stability and alignment during the process.

Step 2: Set the Machine

-

Adjust the grooving machine according to the pipe’s size and groove specifications. Ensure that the cutting tool is positioned correctly.

Step 3: Groove the Pipe

-

Start the machine and slowly guide the cutting tool to create the groove. It is essential to maintain consistent speed and pressure to avoid uneven grooves.

Step 4: Inspect the Groove

-

Once the grooving is complete, inspect the groove’s depth, width, and smoothness. Use measuring tools to ensure the groove meets the required standards.

Step 5: Finish and Clean the Pipe

-

After the grooving is complete, clean the pipe to remove any debris or metal shavings left from the grooving process. This ensures proper sealing when the coupling is attached.

5. Common Issues and Solutions When Grooving Ductile Iron Pipe

5.1. Uneven Grooves

-

Problem: Uneven grooves can lead to poor sealing and weak joints.

-

Solution: Ensure that the grooving machine is calibrated correctly and that the pipe is securely clamped during the process. Regular maintenance of the grooving machine is also essential.

5.2. Cracking of Pipe During Grooving

-

Problem: Cracking can occur if excessive force is applied during the grooving process.

-

Solution: Use the correct settings on the machine to avoid applying too much pressure. Gradually increase speed and pressure to allow the machine to cut smoothly.

5.3. Incorrect Groove Dimensions

-

Problem: If the groove is too shallow or deep, it may not fit the coupling properly.

-

Solution: Use measuring tools to ensure that the groove dimensions match the specifications. Perform quality checks during the process.

6. FAQs on Grooving Ductile Iron Pipe

Q1: What are the key benefits of using grooved ductile iron pipes?

Answer: Grooved ductile iron pipes offer ease of installation, flexibility, and reduced costs. They are commonly used in water, sewage, and industrial systems. The grooved connection system allows for faster installation compared to welding or threading, and the durability and corrosion resistance of ductile iron further enhance the overall performance.

Q2: How can I ensure the correct groove depth and width?

Answer: To ensure the groove is the correct depth and width, it’s essential to use precise measuring tools such as calipers. Additionally, regularly calibrating the grooving machine and conducting quality control checks during the process will help ensure that the dimensions meet the required standards.

Q3: Is grooving ductile iron pipe a complicated process?

Answer: Grooving ductile iron pipes is not a complicated process, but it requires attention to detail and the correct tools. Using a well-maintained grooving machine and ensuring the pipe is securely clamped can help reduce errors and improve the quality of the grooves.

Q4: What is the difference between a standard and Victaulic groove?

Answer: The primary difference lies in the type of coupling used. A Victaulic groove is specifically designed to fit Victaulic couplings, which are commonly used in fire protection and HVAC systems. A standard groove is used for general pipe connections and may not be compatible with all coupling types.

Q5: How long does it take to groove a ductile iron pipe?

Answer: The time it takes to groove a ductile iron pipe depends on the size of the pipe and the type of grooving machine used. Generally, grooving a standard pipe takes between 5 to 15 minutes, depending on the machine and pipe size.

Q6: Can I groove the pipe myself or should I hire a professional?

Answer: Grooving a pipe requires the correct tools and techniques. If you have experience with pipe installations and access to the right equipment, you can groove the pipe yourself. However, if you lack the proper tools or experience, it is recommended to hire a professional to ensure the job is done correctly.

7. Video Tutorial on Grooving Ductile Iron Pipe

8. Conclusion

Grooving ductile iron pipes is a simple yet essential process in modern pipe installation systems. It provides a reliable, cost-effective way to join pipes and fittings while offering flexibility for maintenance and future modifications. With the right tools and techniques, grooving can be done quickly and efficiently, ensuring durable and leak-free pipe systems.

References:

- American Water Works Association (AWWA) Standards for Ductile Iron Pipe and Fittings

- ISO 2531: Ductile iron pipes, fittings, accessories and their joints for water pipelines — Requirements and test methods

- Ductile Iron Pipe – Wikipedia Overview

- Victaulic: Technical Reference for Grooved Pipe Joining Systems

- NFPA 13: Standard for the Installation of Sprinkler Systems (Fire Protection System Standards)