The allowable deflection in ductile iron pipe refers to the maximum safe angular movement permitted at pipe joints to accommodate ground shifts, thermal changes, and installation curves. According to AWWA C150/C151 standards, most push-on and mechanical joints allow 1 to 5 degrees of deflection per joint, depending on pipe size and design. Proper deflection ensures long-term seal integrity while reducing stress on the pipeline system. Contractors must follow manufacturer specifications and alignment best practices to prevent leaks or joint damage. Learn how optimizing deflection enhances durability in water, sewer, and industrial applications.

1. Introduction to Deflection in Ductile Iron Pipes

What is Deflection?

Deflection refers to the movement or bending of a pipe from its original alignment under external forces, such as pressure, soil movement, or temperature changes. In ductile iron pipes, deflection typically occurs at the joints, where two pipes meet. The amount of deflection allowed is crucial in ensuring the pipe’s structural integrity, the efficiency of the pipeline, and its longevity.

Deflection can be angular (bending at the joint), lateral (sideways shifting), or longitudinal (along the pipe’s length). While some deflection is permissible to accommodate soil movement, pressure changes, and minor shifts, excessive deflection can compromise the pipeline’s function and safety.

Why is Deflection Important in Ductile Iron Pipes?

Ductile iron pipes are known for their durability and strength, making them a popular choice for water and wastewater systems, as well as industrial applications. However, like all materials, ductile iron pipes can suffer from deflection under certain conditions.

The main reason deflection is important in ductile iron pipe systems is that excessive movement at the joints can lead to:

-

Misalignment: Pipes that are out of alignment can disrupt the fluid flow or cause pressure problems.

-

Leakage: Shifts in pipe joints can compromise seals, leading to leaks, water loss, or contamination.

-

Structural Damage: Prolonged or severe deflection can cause cracks or fractures in the pipes, requiring costly repairs or replacements.

Maintaining the allowable deflection is essential for ensuring the pipeline’s performance, safety, and longevity.

2. Allowable Deflection in Ductile Iron Pipe Systems

Industry Standards for Deflection

Industry standards set clear guidelines for the allowable deflection in ductile iron pipes. These standards ensure that deflection remains within limits that do not jeopardize the pipe’s integrity or its ability to function properly.

The most commonly referenced standard for deflection in ductile iron pipes is the American Water Works Association (AWWA) C151 specification, which provides guidelines for the design and installation of ductile iron pipes. According to these standards:

-

Maximum allowable deflection for ductile iron pipes is typically 1/4 inch per joint (about 6.35 mm), depending on the diameter of the pipe and the specific joint type used.

-

For flexible joints, such as push-on or restrained joints, deflection allowances can vary based on the design, with some systems allowing up to 5 degrees of angular deflection, depending on factors like pipe diameter and the type of gasket used.

Factors Affecting Allowable Deflection

Several factors influence the allowable deflection in ductile iron pipes:

-

Pipe Diameter: Larger diameter pipes are typically more rigid, meaning they can withstand less deflection compared to smaller diameter pipes.

-

Joint Type: Push-on joints, flanged joints, and restrained joints each have different allowable deflection values based on their design and flexibility.

-

Soil Conditions: The type of soil around the pipe can significantly impact how much deflection is permissible. Softer soils, such as clay, can cause more movement, while stable rock or compacted gravel provides greater support and reduces deflection.

-

Pressure and Temperature: Internal pressure and temperature fluctuations can cause the pipe to expand or contract, which affects the amount of deflection that occurs. High internal pressure or significant temperature changes can increase deflection.

3. Understanding the Types of Deflection

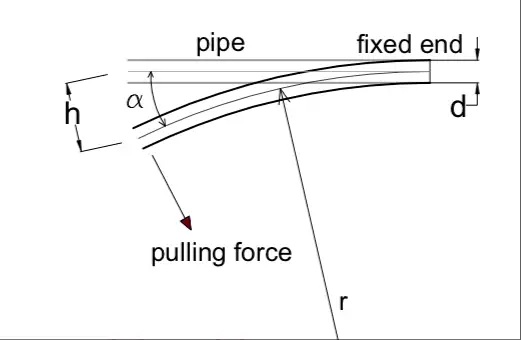

Angular Deflection

Angular deflection occurs when the pipe joints shift at an angle relative to each other. This type of deflection is typically observed in flexible joint designs, such as push-on or mechanical joints, which allow some movement. The typical allowable angular deflection is 5 degrees (about 1/12th of a circle) for push-on joints, though this may vary depending on pipe diameter and application.

Angular deflection is important because excessive angles can lead to joint misalignment, stressing the seals and increasing the risk of leaks.

Lateral Deflection

Lateral deflection is the horizontal shifting of the pipe, which can be caused by external forces like soil settlement, vibrations from nearby traffic, or seismic activity. Excessive lateral deflection can cause significant misalignment between pipe sections, which can impair the pipeline’s ability to carry fluids effectively. In general, lateral deflection should not exceed 1/4 inch per joint.

Longitudinal Deflection

Longitudinal deflection refers to movement along the length of the pipe. This occurs due to internal pressure pushing the pipes apart or due to external forces acting on the pipeline. Longitudinal deflection is usually less common than angular or lateral deflection but can still affect the alignment of a pipeline, particularly if the pipe is improperly anchored or restrained. The allowable longitudinal deflection depends on the specific system design and material properties.

4. Implications of Excessive Deflection

Effects on Structural Integrity

Excessive deflection can weaken the structural integrity of the pipe. Over time, deflection places stress on the pipe material and joints, potentially causing cracks or fractures. Severe deflection may lead to pipe failure, requiring costly repairs or complete replacement.

Leakage Risks and Sealing Issues

When deflection exceeds allowable limits, the seals between pipe joints can become misaligned, leading to gaps. These gaps can result in leakage, which not only causes water loss but may also damage the surrounding environment or structures. Leakage is a major concern, especially in water and wastewater systems, as it can lead to contamination and increased maintenance costs.

Long-term Damage and Failure Risks

Deflection, if left unaddressed, can lead to long-term damage, including pipe misalignment, increased friction, and wear on the pipe joints. This can reduce the lifespan of the pipeline and require frequent repairs, causing downtime and maintenance costs.

5. Designing for Deflection: Key Considerations

Pipe Material and Joint Design

Ductile iron pipes are typically designed to accommodate a certain amount of deflection due to their inherent flexibility and strength. However, the joint design plays a critical role in determining the allowable deflection. Push-on joints, mechanical joints, and restrained joints all have different deflection allowances.

The type of gasket used in the joints also affects how much deflection the system can handle. Elastomeric gaskets, for example, offer a higher level of flexibility and can accommodate more movement.

Soil Conditions and External Loads

Soil type, moisture levels, and external loads such as traffic and nearby construction can affect how much deflection a pipe experiences. Pipes installed in stable, well-compacted soils are less likely to experience significant deflection compared to pipes installed in loose or shifting soils.

Proper bedding and backfill materials are essential for reducing deflection. In areas with high risk of soil movement or seismic activity, additional measures, such as joint restraints or anchors, may be necessary.

Installation Techniques to Minimize Deflection

During installation, it’s important to ensure that pipes are properly aligned and securely supported. This includes using proper trenching techniques, ensuring correct pipe bedding, and using restraints or anchors to secure the pipes in place. By carefully following installation best practices, the likelihood of excessive deflection can be minimized.

6. Table: Comparison of Allowable Deflection in Different Pipe Materials

| Pipe Material | Allowable Angular Deflection | Allowable Lateral Deflection | Advantages | Disadvantages |

|---|---|---|---|---|

| Ductile Iron | Up to 5 degrees | 1/4 inch per joint | Strong, flexible, corrosion-resistant, widely used | Can be expensive, requires careful installation |

| PVC | 1-2 degrees | 1/8 inch per joint | Lightweight, easy to install, cost-effective | Prone to cracking, less flexible than ductile iron |

| Steel | 3-4 degrees | 1/4 inch per joint | Strong, durable, suitable for high-pressure systems | Prone to corrosion without proper coating |

| HDPE | Up to 5 degrees | 1/2 inch per joint | Highly flexible, resistant to cracking and corrosion | Requires specialized fittings, expensive |

7. FAQs

1. What is the standard allowable deflection for ductile iron pipes?

The standard allowable deflection for ductile iron pipes is typically 1/4 inch per joint, depending on the type of joint used and the diameter of the pipe. For flexible joints, the allowable angular deflection can be up to 5 degrees.

2. How do soil conditions influence allowable deflection?

Soil conditions play a critical role in determining how much deflection a ductile iron pipe can tolerate. Softer, more unstable soils can cause greater movement, while more stable soils provide better support for the pipes, allowing for less deflection. Soil compaction, moisture levels, and external forces like traffic or seismic activity should be considered during installation.

3. Can deflection be prevented during installation?

While it’s impossible to prevent all deflection, proper installation techniques can significantly reduce the likelihood of excessive deflection. Using correct bedding materials, ensuring proper alignment, and installing joint restraints or anchors can help minimize movement.

4. What happens if a ductile iron pipe exceeds allowable deflection?

Exceeding the allowable deflection can lead to misalignment at the joints, which can cause joint failure, leakage, and long-term damage to the pipeline. Over time, excessive deflection may compromise the pipe’s structural integrity, increasing maintenance costs and decreasing the system’s lifespan.

5. How can I measure deflection in ductile iron pipe systems?

Deflection can be measured using specialized tools such as a laser level, dial gauge, or total station. These instruments can detect angular, lateral, or longitudinal movement at the joints. Regular inspections and measurements should be conducted to monitor deflection and ensure the system’s integrity.

Conclusion: Managing Deflection in Ductile Iron Pipelines

Understanding and managing allowable deflection is essential for ensuring the longevity and performance of ductile iron pipe systems. By following industry standards, accounting for environmental factors, and employing proper installation techniques, pipeline operators can significantly reduce the risk of excessive deflection and the associated problems. Regular inspection and maintenance are also critical for detecting potential issues early and preserving the integrity of the pipeline system.