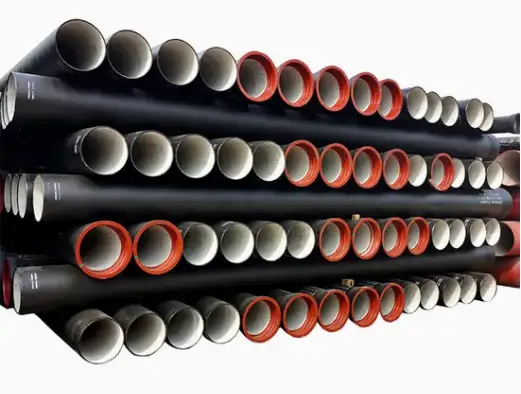

Ductile iron pipes are essential components in modern infrastructure, particularly for water and wastewater systems. Understanding the cost of a 6-inch ductile iron pipe is crucial for budgeting and planning in construction projects.

1. Factors Influencing the Cost of 6-Inch Ductile Iron Pipe

1.1 Material Specifications

The cost of ductile iron pipes varies based on several material specifications:

-

Class Rating: Pipes are classified based on their pressure rating. For instance, Class 350 indicates a pressure rating of 350 psi.

-

Coatings and Linings: Internal linings, such as cement mortar or epoxy, and external coatings like polyethylene, can add to the cost but are essential for corrosion resistance.

-

Joint Types: The method of joining pipes, such as push-on or mechanical joints, affects both cost and installation complexity.

1.2 Manufacturing Standards

Compliance with standards like ANSI/AWWA C151/A21.51 ensures quality and can influence pricing. Pipes meeting higher standards may incur additional costs due to stringent manufacturing processes.

1.3 Regional Price Variations

Prices can differ based on geographic location due to factors like local manufacturing capabilities, transportation costs, and regional demand. For example, prices in urban areas may be higher due to increased demand and logistics costs.

2. Cost Breakdown of 6-Inch Ductile Iron Pipe

2.1 Unit Price

The unit price of a 6-inch ductile iron pipe can vary:

-

Standard Class 350: Approximately $30.75 per foot .

-

Class 52: Around $17.97 per foot .

2.2 Additional Costs

-

Coatings and Linings: Adding internal linings and external coatings can increase the price by $5 to $10 per foot.

-

Joint Types: Mechanical joints may add $2 to $5 per foot compared to push-on joints.

-

Transportation: Delivery costs vary based on distance from the supplier and can range from $1 to $3 per foot.

2.3 Total Estimated Cost

Considering the base price and additional costs, the total estimated cost for a 6-inch ductile iron pipe can range from $35 to $50 per foot.

3. Installation Considerations

3.1 Labor Costs

Installation labor costs depend on factors such as trenching, pipe laying, and jointing. On average, labor costs can range from $10 to $20 per foot.

3.2 Equipment Costs

The use of machinery like trenchers and cranes can add to the installation cost. Equipment rental or usage fees can range from $5 to $15 per foot.

3.3 Total Installation Cost

Including labor and equipment, the total installation cost for a 6-inch ductile iron pipe can range from $50 to $100 per foot.

4. Comparative Analysis

To provide a clearer understanding, here’s a comparison of ductile iron pipes with other materials:

| Pipe Material | Estimated Cost per Foot | Durability | Corrosion Resistance | Installation Complexity |

|---|---|---|---|---|

| Ductile Iron | $35 – $50 | High | Excellent | Moderate |

| PVC | $10 – $20 | Moderate | Low | Easy |

| Steel | $25 – $40 | High | Moderate | High |

5. Frequently Asked Questions (FAQs)

5.1 What is the lifespan of a 6-inch ductile iron pipe?

A well-maintained ductile iron pipe can last over 100 years, making it a cost-effective choice in the long term.

5.2 Can ductile iron pipes be used for both water and sewer systems?

Yes, ductile iron pipes are versatile and can be used for both potable water and sewer applications.

5.3 How do I choose the right class rating for my project?

The class rating should be selected based on the expected internal pressure in the system. Higher class ratings are suitable for higher pressure applications.

5.4 Are there environmentally friendly options available?

Yes, some manufacturers offer ductile iron pipes with environmentally friendly coatings and linings to reduce environmental impact.

5.5 How does the cost of ductile iron compare to other materials over time?

While the initial cost of ductile iron may be higher, its durability and low maintenance requirements often result in lower total lifecycle costs compared to materials like PVC or steel.

6. Conclusion

Understanding the cost factors associated with 6-inch ductile iron pipes is essential for effective project planning and budgeting. By considering material specifications, regional price variations, and installation requirements, stakeholders can make informed decisions that align with both financial and operational goals.