Ductile Iron Pipes (DIP) are a modern evolution of traditional cast iron pipes, offering enhanced strength, flexibility, and durability. They are primarily used in water and wastewater systems, as well as in industrial applications. The primary advantage of ductile iron over traditional cast iron is its ability to withstand higher internal pressures and external stresses.

1. Understanding Wall Thickness in Ductile Iron Pipes

The wall thickness of a ductile iron pipe is a critical parameter that determines its pressure rating and structural integrity. It is influenced by factors such as internal pressure, external loads, and the type of joint used.

Key Concepts:

-

Nominal Wall Thickness: The standard thickness specified for a given pipe size and pressure class.

-

Actual Wall Thickness: The measured thickness of the pipe wall, which may vary slightly due to manufacturing tolerances.

-

Pressure Class: Indicates the maximum internal pressure a pipe can withstand, typically ranging from 150 to 350 psi.

2. Standards and Specifications

Various standards govern the design and manufacturing of ductile iron pipes, ensuring consistency and reliability.

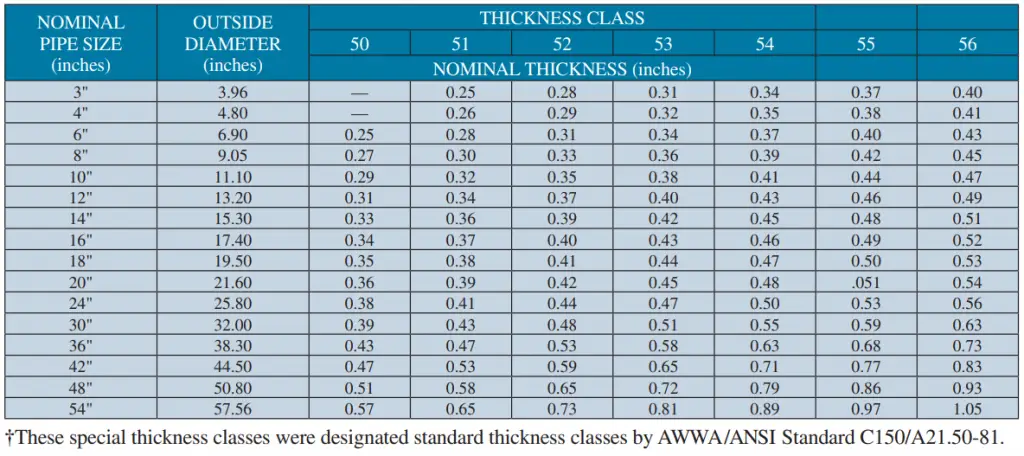

AWWA C150/A21.50

This standard provides guidelines for the design of ductile iron pipes, including calculations for wall thickness based on internal pressure and external loads. It also specifies allowances for casting and service conditions.

AWWA C151/A21.51

This standard specifies the requirements for the materials and manufacturing processes of ductile iron pipes, including dimensions, tolerances, and pressure classes.

3. Factors Influencing Wall Thickness

Several factors influence the required wall thickness of a ductile iron pipe:

-

Internal Pressure: Higher internal pressures necessitate thicker walls to prevent failure.

-

External Loads: Buried pipes subjected to external loads, such as traffic or soil weight, require increased wall thickness.

-

Pipe Diameter: Larger diameter pipes generally require thicker walls to maintain structural integrity.

-

Joint Type: Restrained joints may allow for reduced wall thickness compared to non-restrained joints.

4. Calculation Methods for Wall Thickness

The calculation of wall thickness involves several steps:

-

Determine Internal Pressure: Assess the maximum internal pressure the pipe will experience.

-

Calculate Required Wall Thickness: Use formulas such as Barlow’s equation to calculate the minimum required wall thickness.

-

Apply Allowances: Add allowances for casting tolerances and service conditions as specified in relevant standards.

-

Select Appropriate Pressure Class: Choose a pressure class that meets or exceeds the calculated requirements.

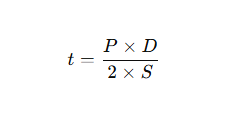

For example, using Barlow’s equation:

Where:

-

ttt = wall thickness

-

PPP = internal pressure

-

DDD = outside diameter

-

SSS = allowable stress

5. Applications and Use Cases

Ductile iron pipes are utilized in various applications:

-

Water Distribution: Transporting potable water across urban and rural areas.

-

Wastewater Systems: Conveying sewage and stormwater.

-

Industrial Applications: Used in chemical and power plants for fluid transport.

-

Fire Protection: Serving as the backbone for fire hydrant systems.

6. Maintenance and Longevity

Ductile iron pipes are known for their longevity, often exceeding 100 years of service life. Regular maintenance, such as monitoring for corrosion and ensuring proper joint integrity, is essential to maximize their lifespan.

7. FAQs

Q1: What is the typical wall thickness for a 12-inch ductile iron pipe?

A 12-inch ductile iron pipe typically has a wall thickness ranging from 0.31 inches to 0.35 inches, depending on the pressure class.

Q2: How does the joint type affect wall thickness requirements?

Restrained joints allow for reduced wall thickness compared to non-restrained joints, as they provide additional structural support.

Q3: Can ductile iron pipes be used for high-temperature applications?

Ductile iron pipes are generally not recommended for high-temperature applications due to potential material degradation.

Q4: What is the maximum internal pressure a ductile iron pipe can handle?

The maximum internal pressure depends on the pipe’s diameter, wall thickness, and pressure class, but typically ranges up to 350 psi.

Q5: Are there alternatives to ductile iron pipes?

Yes, alternatives include PVC, HDPE, and steel pipes, each with its own advantages and limitations.

Q6: How can I calculate the required wall thickness for my application?

Utilize standards such as AWWA C150/A21.50 and calculation tools provided by organizations like DIPRA to determine the appropriate wall thickness.

References:

- AWWA C150 – Standard for Ductile Iron Pipe Design – American Water Works Association (AWWA)

- AWWA C151 – Standard for Ductile Iron Pipe Materials and Manufacturing – American Water Works Association (AWWA)

- Ductile Iron Pipe Standards – American Society of Civil Engineers (ASCE)

- ISO 2531 – Ductile Iron Pipes – International Organization for Standardization (ISO)

- Ductile Iron – Wikipedia