Ductile iron is one of the most durable materials used in manufacturing pipes and fittings for various industrial applications. The Ductile Iron 80 60 03 grade is commonly used in the industry due to its excellent mechanical properties and long service life. This article delves into the key aspects of Ductile Iron 80 60 03, including its equivalents, pricing, and dimensions, along with detailed comparisons to help you make informed decisions.

1. What is Ductile Iron 80 60 03?

Ductile Iron 80 60 03 is a specific grade of ductile iron that offers enhanced strength and resilience compared to other materials. The number “80 60 03” refers to its mechanical properties, particularly its tensile strength and elongation characteristics, measured in MPa (megapascals). Ductile Iron 80 60 03 is commonly used in pipe systems, valve components, and fittings, thanks to its robustness and ability to withstand high pressures.

-

80: Represents the minimum tensile strength (in MPa) of the material.

-

60: Refers to the minimum yield strength (in MPa).

-

03: Indicates the elongation percentage, a measure of the material’s ability to stretch under stress.

2. Mechanical Properties of Ductile Iron 80 60 03

Ductile Iron 80 60 03 possesses superior mechanical properties compared to conventional gray iron. Below are the key mechanical properties:

| Property | Ductile Iron 80 60 03 |

|---|---|

| Tensile Strength | 80 MPa (minimum) |

| Yield Strength | 60 MPa (minimum) |

| Elongation | 3% (minimum) |

| Hardness | 200-250 HB |

| Impact Toughness | High |

| Modulus of Elasticity | 170 GPa |

These properties make Ductile Iron 80 60 03 suitable for a wide range of applications, including water and sewage systems, pressure pipes, and heavy-duty fittings.

3. Equivalents of Ductile Iron 80 60 03

Ductile Iron 80 60 03 is often compared to similar grades used internationally. Some equivalents include:

-

EN-GJS-400-18-LT (European Standard)

-

ASTM A536 60-40-18 (American Standard)

-

ISO 1083 Grade 400-18

While these equivalents share similar mechanical properties, there may be slight variations in chemical composition, which can affect their performance in different environments. Choosing the right equivalent depends on the specific requirements of the project, such as pressure rating, temperature conditions, and corrosion resistance.

4. Applications of Ductile Iron 80 60 03

Ductile Iron 80 60 03 is used in various applications that require high strength and impact resistance. Some common uses include:

-

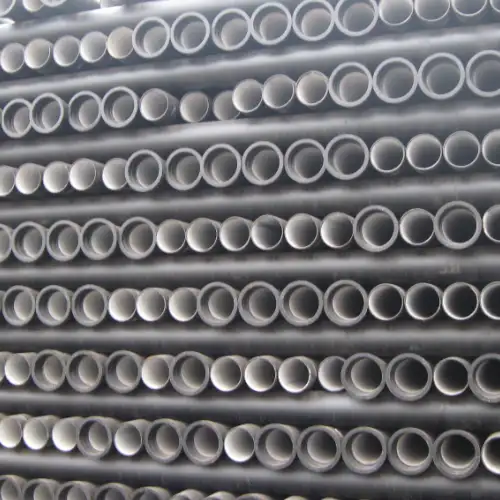

Piping Systems: Especially for water, sewage, and industrial pipes.

-

Valve Components: Such as valve bodies, casings, and covers.

-

Fittings: Including flanges, bends, and couplings.

-

Heavy-Duty Industrial Equipment: Components subjected to high stress, like machinery parts.

Its superior mechanical properties make it particularly ideal for applications involving high-pressure systems and harsh environmental conditions.

5. Price of Ductile Iron 80 60 03

The price of Ductile Iron 80 60 03 varies depending on several factors, including:

-

Quantity: Larger orders typically benefit from reduced per-unit costs.

-

Supplier Location: Regional differences and transportation costs can affect pricing.

-

Customization: Custom manufacturing (e.g., special coatings or dimensions) can raise the price.

On average, the price for Ductile Iron 80 60 03 can range from $2 to $3 per kilogram depending on market conditions and the volume of the order.

| Supplier Location | Estimated Price Range (per kg) |

|---|---|

| China | $2.10 – $2.60 |

| Europe | $2.30 – $3.00 |

| United States | $2.50 – $3.00 |

6. Dimensions of Ductile Iron 80 60 03

Ductile Iron 80 60 03 is manufactured in various dimensions depending on the intended application. The most common dimensions include:

-

Pipe Sizes: From DN 50 (2 inches) to DN 1500 (60 inches).

-

Wall Thickness: 5mm to 30mm.

-

Length: Custom lengths are available depending on the specifications of the order.

Dimensions are typically standardized according to international standards like ISO 1083 or ASTM A536.

7. Manufacturing Process of Ductile Iron 80 60 03

The production of Ductile Iron 80 60 03 involves a process known as continuous casting. The material is heated to a molten state and poured into molds, where it solidifies into the required shapes (pipes, fittings, or valve bodies). The continuous casting process ensures consistency in quality and helps maintain precise mechanical properties.

Key steps in the manufacturing process include:

-

Melting: Iron is melted in an electric arc furnace.

-

Alloying: Various elements like magnesium, silicon, and sulfur are added to achieve the desired properties.

-

Casting: The molten iron is poured into molds and allowed to cool.

-

Heat Treatment: The castings undergo a heat treatment process to further enhance their mechanical properties.

8. Benefits of Ductile Iron 80 60 03

Ductile Iron 80 60 03 offers several advantages, including:

-

High Strength: Provides excellent tensile and yield strength.

-

Impact Resistance: Can withstand heavy impacts without cracking.

-

Corrosion Resistance: Performs well in aggressive environments like sewage systems.

-

Cost-Effective: Offers a lower cost solution compared to other high-strength materials like stainless steel.

-

Versatility: Can be customized for various applications and industries.

9. Comparing Ductile Iron 80 60 03 with Other Materials

When choosing materials for your projects, it’s essential to compare Ductile Iron 80 60 03 with other materials such as stainless steel or cast steel. Below is a comparison table:

| Property | Ductile Iron 80 60 03 | Stainless Steel | Cast Steel |

|---|---|---|---|

| Tensile Strength | 80 MPa | 500 MPa | 400 MPa |

| Yield Strength | 60 MPa | 250 MPa | 350 MPa |

| Elongation | 3% | 30% | 12% |

| Hardness | 200-250 HB | 150-180 HB | 220 HB |

| Corrosion Resistance | Moderate | Excellent | Good |

| Cost | Low | High | Medium |

This comparison helps identify the most suitable material for specific needs based on factors like strength, cost, and corrosion resistance.

10. Key Considerations When Choosing Ductile Iron 80 60 03

When selecting Ductile Iron 80 60 03 for your project, consider the following factors:

-

Application Requirements: Assess the mechanical demands and environmental conditions.

-

Cost Constraints: Consider your budget and whether Ductile Iron 80 60 03 offers the best value for your project.

-

Custom Manufacturing: If custom sizes or shapes are required, ensure that your supplier can accommodate these needs.

-

Supplier Reputation: Choose a reputable supplier like Luokaiwei, a leading manufacturer of ductile iron products, to ensure quality and reliability.

Frequently Asked Questions (FAQs)

1. What is the difference between Ductile Iron 80 60 03 and other ductile iron grades?

Ductile Iron 80 60 03 is a medium-grade material with balanced strength and elongation. It is ideal for use in high-pressure systems but may not offer the same level of tensile strength or corrosion resistance as other higher-grade materials. Compared to grades like Ductile Iron 100 70 03, it has a slightly lower tensile strength but offers better flexibility.

2. How is the price of Ductile Iron 80 60 03 determined?

The price is influenced by several factors, including market demand, the volume of the order, and the complexity of the material. Additional factors like customization (e.g., coatings or specific dimensions) can also impact the price.

3. Is Ductile Iron 80 60 03 suitable for outdoor installations?

Yes, Ductile Iron 80 60 03 is well-suited for outdoor applications, especially when used in water or sewage pipes. Its resistance to corrosion and ability to withstand harsh environmental conditions make it a preferred choice for outdoor systems.

4. How does Ductile Iron 80 60 03 compare to stainless steel in terms of corrosion resistance?

While stainless steel has superior corrosion resistance, Ductile Iron 80 60 03 is more cost-effective and still performs well in corrosive environments, particularly when used with protective coatings. For less aggressive environments, Ductile Iron 80 60 03 is an excellent alternative to stainless steel.

5. Can Ductile Iron 80 60 03 be used in seismic areas?

Yes, Ductile Iron 80 60 03 is capable of handling seismic conditions. Its toughness and ability to deform without breaking make it suitable for installations in seismic zones, especially when used in pipeline systems.

6. What is the best method for joining Ductile Iron 80 60 03 pipes and fittings?

The best method for joining Ductile Iron 80 60 03 pipes and fittings is typically through flanged joints or mechanical couplings. Welding is generally not recommended due to the material’s high carbon content, which can affect the weldability.

Conclusion

Ductile Iron 80 60 03 is a versatile, cost-effective material with excellent mechanical properties, making it ideal for various industrial applications. Its strength, impact resistance, and corrosion resistance, combined with its affordability, make it a popular choice for pipes, valves, and fittings. By understanding its equivalents, price range, and dimensions, you can make informed decisions about its use in your projects.

References:

- ASTM A536 – Standard Specification for Ductile Iron Castings (ASTM International)

- ISO 1083:2018 – Spheroidal graphite cast irons (International Organization for Standardization)

- Ductile Iron – Mechanical Properties and Applications (Wikipedia)

- Dura-Bar Ductile Iron Specifications – Including 80-60-03 Grade

- Modulus of Elasticity for Metals – Reference Table (Engineering Toolbox)