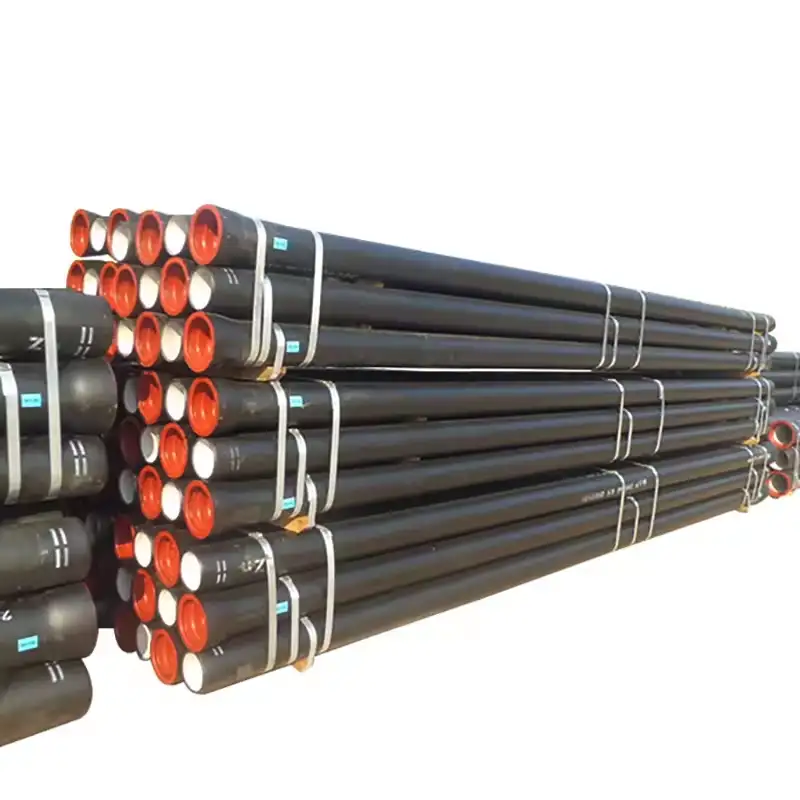

The DN800mm ductile iron pipe is a robust and versatile solution for large-scale water and wastewater infrastructure projects. Renowned for its strength, longevity, and compliance with international standards, it serves as a reliable choice for municipalities and industries worldwide.

Material & Mechanical Properties

Ductile iron pipes are manufactured using spheroidal graphite cast iron, offering superior mechanical properties compared to traditional gray cast iron. They exhibit high tensile strength, excellent elongation, and enhanced impact resistance.

Mechanical Properties Comparison

| Material Type | Tensile Strength | Elongation | Hardness (HB) |

|---|---|---|---|

| Ductile Iron Pipe | ≥420 N/mm² | ≥10% | ≤230 |

| Gray Cast Iron Pipe | 150–260 N/mm² | Negligible | ≤230 |

| Steel Pipe | ≥400 N/mm² | ≥18% | Approx. 140 |

Source: TOPSUN Ductile Iron Pipe Specifications

🌍 Applications

DN800mm ductile iron pipes are suitable for various applications, including:

-

Potable water transmission.

-

Sewerage and stormwater systems.

-

Irrigation networks.

-

Mining slurry pipelines.

-

Industrial fluid transport.

These pipes are designed for both buried and above-ground installations, ensuring versatility across different terrains.

📊 Technical Specifications

| Diameter (mm) | Wall Thickness (mm) | Weight per 6m Length (kg) | Pressure Class | Joint Type |

|---|---|---|---|---|

| 800 | 10–12 | 1,500–1,800 | PN25 | RRJ |

Note: RRJ refers to Rubber Ring Joint, a standard connection method for ductile iron pipes.

⏳ Lifespan & Durability

Modern ductile iron pipes are engineered to last over 100 years, provided they are properly designed and installed. Their durability is attributed to:

-

High resistance to internal and external corrosion.

-

Effective cement mortar linings.

-

Recycled content and recyclability, enhancing environmental sustainability.

🔧 Installation & Connection

Ductile iron pipes are typically connected using:

Proper installation ensures leak-free joints and optimal system performance. Detailed installation guides are available from the Ductile Iron Pipe Research Association (DIPRA) to assist engineers and contractors.

🌐 International Standards

DN800mm ductile iron pipes comply with several international standards, including:

-

ISO 2531:2009 – Ductile iron pipes, fittings, accessories, and their joints for water applications.

-

EN 545:2010 – Ductile iron pipes, fittings, accessories, and their joints for water pipelines.

-

ISO 7186:2009 – Ductile iron products for sewerage applications.

These certifications ensure product quality and compatibility across global markets.

💰 Price Comparison (Sample Data)

| Diameter (mm) | Pressure Class | Price Range (USD/6m Length) |

|---|---|---|

| DN800 | PN25 | $1,200 – $1,500 |

| DN1000 | PN25 | $1,500 – $1,800 |

| DN1200 | PN25 | $1,800 – $2,200 |

Note: Prices vary based on manufacturer, material specifications, and regional factors.

✅ Advantages

-

High strength and durability.

-

Corrosion resistance.

-

Long service life.

-

Compliance with international standards.

-

Environmental sustainability.

❓ Frequently Asked Questions (FAQ)

Q: What is the maximum pressure rating for DN800mm ductile iron pipes?

A: The maximum pressure rating is typically PN25, equivalent to 2,500 kPa.

Q: Can these pipes be used for both potable water and sewage systems?

A: Yes, ductile iron pipes are suitable for both applications, provided they meet the necessary standards.

Q: What is the recommended installation depth for these pipes?

A: Installation depth varies based on local conditions and regulations. Consult local guidelines and standards for specific requirements.

📌 Case Study: Municipal Water Supply Project

In a recent municipal water supply project, DN800mm ductile iron pipes were installed to replace aging infrastructure. The project resulted in:

-

Improved water quality and pressure.

-

Reduced maintenance costs.

-

Enhanced system reliability.

The successful implementation demonstrates the efficacy of ductile iron pipes in modernizing water supply systems.