China’s ductile iron fittings catalog encompasses a wide array of components—elbows, tees, reducers, crosses, flanges, couplings, caps, plugs, and specialty fittings—manufactured to international and regional standards (ISO 2531/EN 545, AWWA C110/C153, ANSI B16.1, IS 9523) to serve water, wastewater, gas, and industrial piping systems. Each fitting’s geometry, pressure rating (K7–K12 per ISO; Class 150–350 per AWWA), joint type (flanged, mechanical joint, push-on), and coating (cement-mortar, epoxy, polyethylene, zinc) influence its dimensions, weight, and performance characteristics. Accurate catalog data is critical for design, procurement, installation, and maintenance, ensuring compatibility, reliability, and cost-effectiveness across projects of all scales.

1. Catalog Structure & Ordering Process

1.1 Catalog Format & Navigation

Most ductile iron fittings catalogs are published in PDF and interactive online formats, organized by fitting type (elbows, tees, reducers), size (DN/Inch), pressure class, and joint style. Subsections include dimensional tables, weight tables, material specifications, coating options, and ordering codes.

1.2 Part Number & Ordering Code Logic

Fabricators assign part numbers combining nominal diameter, pressure class code (e.g., K9 for 250 psi), joint type suffix (MJ for mechanical joint, FL for flanged), and coating code (CM for cement‐mortar, EP for epoxy). For example, a DN 150, Class 250, mechanical joint, cement-mortar-lined elbow might be cataloged as “ELB‐150‐K9‐MJ‐CM”.

1.3 Minimum Order Quantities & Lead Times

Standard fittings often ship in batches of 10–20 pieces, with lead times of 2–4 weeks for common sizes and 6–8 weeks for large-diameter or specialty orders. Expedited services may be available at additional cost.

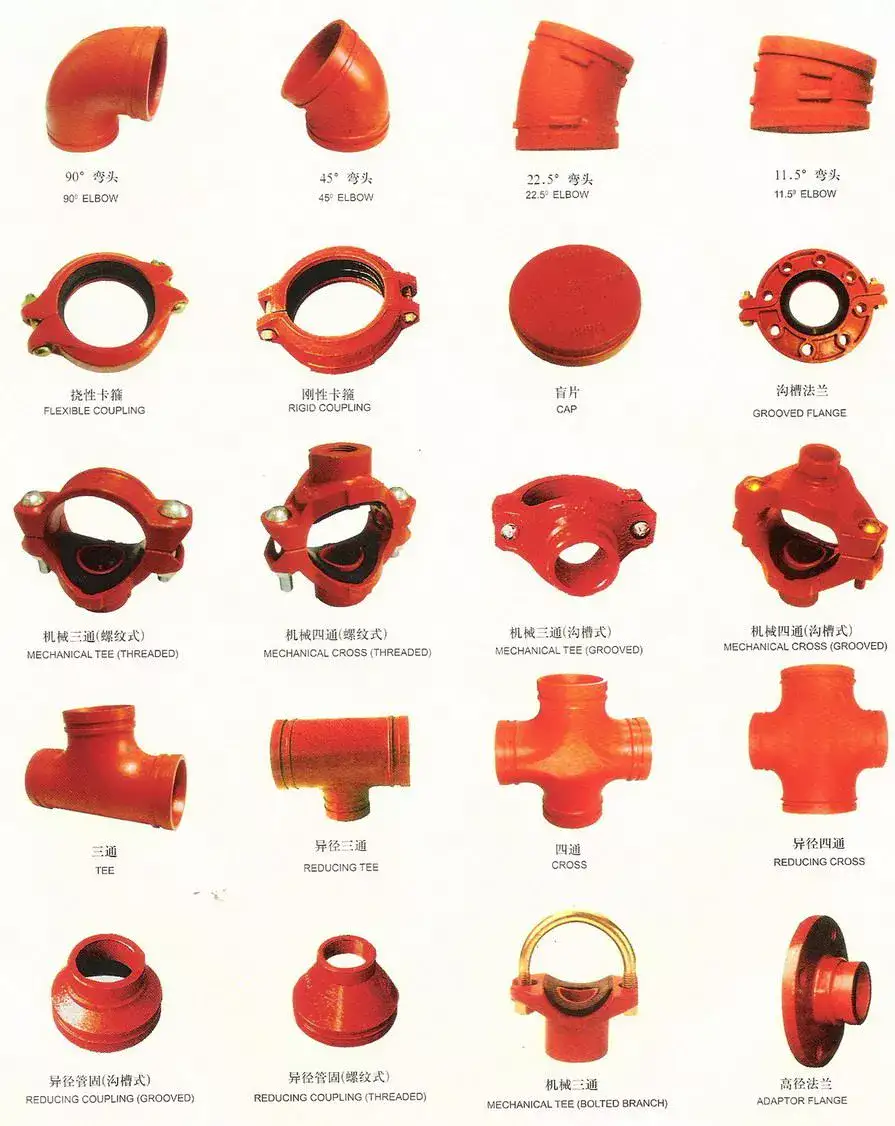

2. Types of Ductile Iron Fittings

2.1 Elbows

Elbows change pipeline direction, available in 45° and 90° angles, long-radius (LR = 1.5×DN) and short-radius (SR = 1×DN) variants. Long-radius elbows reduce head loss and are preferred in high-velocity systems; short-radius elbows save space in compact layouts.

2.2 Tees & Wyes

Tees connect three pipes at 90°; available as equal-branch and reducing; branch/runs designated as DN_R×DN_B (e.g., 200×150). Wyes (Y-branch) provide smoother flow splits at 45° branch angles, minimizing turbulence in wastewater applications.

2.3 Reducers & Adapters

Reducers transition between two diameters; available in concentric and eccentric styles; eccentric reducers maintain bottom alignment in horizontal runs to prevent air pockets . Flange adapters (flange x spigot) enable connection of pipe to valves or equipment with different end styles .

2.4 Crosses & Special Fittings

Crosses join four pipes; less common due to thrust concerns, often used with thrust blocks. Specialty fittings include seismic joints, expansion joints, deflection fittings, and fabricated offsets for unique site conditions .

2.5 Caps & Plugs

End caps (female-socket) and plugs (male-spigot) seal pipeline ends for pressure testing or system termination; available in mechanical joint and push-on styles.

3. Materials & International Standards

3.1 Ductile Iron Grades

Most fittings use Grade 60-42-10 or 65-45-12 per ASTM A536, providing tensile strength ≥ 60 ksi, yield ≥ 42 ksi, and elongation ≥ 10 %. Low-temperature grades (AD-515) maintain toughness in cold climates.

3.2 Pipe & Fitting Standards

-

ISO 2531 / EN 545 / EN 598: Dimensions, mechanical properties, joint performance for water/sewage.

-

AWWA C110 / ANSI B16.1: Flanged fittings, Class 150, rated 150 psi, DN 80–DN 1200.

-

AWWA C153: Mechanical joint fittings, high pressure Class 250, improved weight savings.

-

ASTM A536: Ductile iron castings for fittings.

-

IS 9523: Indian fitting specifications with weight tables.

3.3 Quality Management & Certification

Reputable manufacturers maintain ISO 9001:2015 quality systems, ISO 14001 environmental management, and ISO 45001 safety standards. Factory Mutual (FM) approvals and NSF 61 drinking-water certifications further validate product integrity .

4. Dimensional & Performance Specifications

4.1 Dimensional Tables

Table 4.1: 90° Long-Radius Elbows (Dimensions in mm)

| DN | OD (EN 545) | ID (ISO 2531) | Centre-to-Face (LR) | Wall Thk (K9) | Weight (kg) |

|---|---|---|---|---|---|

| 80 | 98 | 90 | 120 | 6.3 | 7.2 |

| 150 | 170 | 160 | 225 | 7.7 | 18.0 |

| 300 | 326 | 315 | 450 | 9.0 | 46.0 |

Sources: ISO 2531; EN 545.

4.2 Pressure & Thickness Classes

| Standard | Class | Pressure (psi) | Wall Thk (mm) |

|---|---|---|---|

| AWWA C110 | 150 (K7) | 150 | 8.0–16.0 |

| AWWA C153 | 250 (K9) | 250 | 10.0–20.0 |

| AWWA C153 | 350 (K12) | 350 | 12.0–24.0 |

Data per AWWA C110/C153 tables.

4.3 Hydraulic & Mechanical Performance

Fittings undergo hydrostatic tests at 1.5× rated pressure, performance tests for joint pull-out ≥ 2× working pressure, and deflection tests per ISO 2531/EN 545 . Tensile, hardness, and impact tests follow ASTM A536 mandates.

5. Jointing Methods & Accessories

5.1 Flanged Joints

Flanges (ANSI B16.1/AWWA C110) feature raised or flat faces, bolt-hole drilling per AWWA C115 or ANSI patterns . Gaskets (rubber, PTFE) seal under bolt torque; bolting sequences ensure uniform seating.

5.2 Mechanical Joints (MJ)

Mechanical joint fittings (AWWA C153) use gland, bolts, and rubber gasket; allow limited deflection (up to 5° per joint) . MJ assemblies facilitate faster trench installation and restrained-joint options (e.g., Mega-Lug) resist thrust without concrete blocks.

5.3 Push-On & Restraint Joints

Push-on (Tyton®) joints provide simple spigot-and-socket assembly; restraint variants incorporate metal inserts or external clamps for thrust resistance . Restraint capacities rated per AWWA C111 pull-out tests.

5.4 Special Joint Accessories

Accessory items include joint gaskets (EPDM, nitrile), thrust collars, restraining rods, and flange adapters. Some catalogs offer polyurethane encasement kits per AWWA C105 for corrosion protection.

6. Coatings & Linings

6.1 Internal Linings

-

Cement-Mortar (DIPRA/AWWA C104): Standard lining (min. 1.0 mm thick) for potable water; inhibits tuberculation; bond strength ≥ 2.1 MPa.

-

Epoxy/Polyurethane: Heavy-duty epoxy per EN 14901 or AWWA C210 for aggressive waters; thickness 250–500 µm; NSF 61 certified.

6.2 External Coatings

-

Asphaltic/Bituminous: 1 mil seal coat per AWWA C151; basic corrosion barrier.

-

Zinc-Silicate: 200 g/m² zinc layer with bituminous top coat; per AWWA C151.

-

Polyethylene Encasement (AWWA C105): 0.5 mm wrap, cathodic protection; used in corrosive soils.

7. Installation & Maintenance

7.1 Installation Best Practices

Proper alignment, beveling of pipe ends, joint lubrication, and torque-controlled bolting ensure leak-free assemblies . Use of vacuum lifting devices and spreader bars prevents flange damage.

7.2 Thrust Restraint & Bedding

Restraint methods include thrust blocks (concrete), mechanical restraints (Mega-Lug), and torque-shield gaskets; bedding per ASTM D2321 ensures uniform support and prevents pipe ovalization.

7.3 Routine Inspection & Repair

Visual inspections for coating damage, flange gasket leaks, and corrosion via holiday detectors. Repair kits (DIPRA approved) enable on-site patching of lining/coat defects.

7.4 Winter & Cold-Climate Considerations

Pre-heating fittings with hot water in subzero conditions improves gasket flexibility and seating . Select low-temperature ductile grades (ASTM A536 Grade 80-60-03) for frost-resistant performance.

8. Digital Catalog Tools & Resources

8.1 Online Configurators & BIM Objects

Leading manufacturers provide online configurators: select fitting type, size, joint, lining, and export CAD/BIM files (Revit, AutoCAD) for design integration.

8.2 Mobile Apps & QR-Code Catalogs

Mobile apps allow field technicians to scan QR codes on fittings for specs, installation videos, and maintenance logs.

8.3 Data Sheets & Technical Support

PDF data sheets include dimensional and weight tables, pressure ratings, material certificates, and order code cross-reference . Live chats and technical hotline ensure rapid query resolution.

Six Frequently Asked Questions

Q1: How do I interpret the part number in a ductile iron fittings catalog?

A catalog part number typically encodes the fitting type (ELB, TE, RD), nominal diameter (e.g., 150 for DN 150), pressure class code (K7, K9, K12), joint style (MJ, FL, PO), and lining/coating code (CM, EP, PE). For example, ELB-200-K9-MJ-CM denotes a DN 200, Class 250 (K9), mechanical joint elbow with cement-mortar lining. Manufacturers append special-order suffixes for tapped bosses (B), lifting lugs (L), or restraining inserts (R). Always consult the catalog’s ordering guide for exact code structures, as some firms may use additional characters for packaging units or material certificates. Accurate interpretation prevents order errors and project delays by ensuring the correct configuration is supplied.

Q2: What factors influence the weight differences between AWWA and ISO ductile iron fittings?

While both standards specify fundamental geometry, differences arise in wall thickness requirements, flange dimensions, and machining allowances. AWWA C153 mechanical joint fittings are optimized for weight savings with thinner walls (10–20 mm for Class 250) compared to ISO 2531 K9 (typically 6.3 mm for DN 150), but include heavier gland assemblies, resulting in net weight differences. Flanged fittings per AWWA C110 have larger bolt circles and thicker flanges to mate with AWWA C115 pipe flanges, whereas EN 545 flanged fittings use EN 1092-2 flange dimensions, which can be slimmer. Manufacturers’ empirical weight tables reflect these standard-driven geometry changes; always reference the correct standard’s table for precise mass calculations.

Q3: How do I choose between cement-mortar and epoxy internal linings?

Cement-mortar lining (AWWA C104) is the industry workhorse for potable water, providing cost-effective corrosion resistance and smooth hydraulics; minimum thickness 1 mm, bond strength ≥ 2.1 MPa. It’s proven over 100 years and easily inspected for delamination. Epoxy linings (AWWA C210; EN 14901 heavy‐duty) offer superior chemical resistance, ideal for aggressive water chemistries or wastewater reuse, with 250–500 µm thickness and NSF 61 certification. Epoxies cost 20–30 % more and require stricter surface prep and cure times. Select epoxy when water TDS, pH extremes, or chloramine concentrations exceed cement’s protective limits; otherwise, cement-mortar’s lower cost and established performance make it the default choice.

Q4: What are the benefits of mechanical joint vs. push-on restrained fittings?

Mechanical joint (MJ) fittings (AWWA C153) use a gland and gasket arrangement, allowing controlled deflection (up to 5°) and easy disassembly for maintenance. MJ assemblies, when paired with restraining glands (e.g., Megalug®), provide robust thrust resistance without thrust blocks, saving excavation time. Push-on restrained joints (Tyton® restraint, per AWWA C111) integrate a high-strength steel insert in the gasket, offering similar restraint capacities with fewer components. Push-on restrained joints streamline installation, reduce parts count, and eliminate bolting; however, MJ fittings can be re-torqued and reused more readily. Choice depends on site constraints, joint movement requirements, and maintenance strategy.

Q5: How should ductile iron fittings be stored on site to prevent damage?

Fittings must be kept off the ground on timber skids or pallets to avoid contact with soil moisture and debris, which can damage coatings . Cover stacks with waterproof tarpaulins to prevent rain accumulation inside openings. Do not stack beyond manufacturer’s recommended tier height—usually three high—to prevent flange distortion. Separate different lining/coating lots to prevent mix-ups. Inspect coatings and gaskets before installation; any damage should be repaired per DIPRA guidelines using approved touch-up kits. Proper storage preserves coating integrity, gasket elasticity, and dimensional accuracy, ensuring first-install success .

Q6: What digital resources exist for selecting and specifying ductile iron fittings?

Leading suppliers offer online configurators where engineers select fitting type, DN, class, joint, and lining, instantly generating CAD/BIM downloads (Revit, AutoCAD), cut sheets, and weight tables . Mobile apps enable field scanning of QR codes printed on fittings to retrieve specifications, installation videos, and maintenance history . Industry associations (DIPRA, DuctileIron.org) provide free technical bulletins, standard summaries, and training modules. These digital tools accelerate design cycles, reduce errors, and integrate seamlessly into modern BIM workflows.

References:

- ISO 2531: Ductile Iron Pipes, Fittings, Accessories and Their Joints for Water Applications — International Organization for Standardization

- AWWA Standards: C110, C153, C104, C210 — American Water Works Association

- ASTM A536: Standard Specification for Ductile Iron Castings — ASTM International

- EN 545: Ductile Iron Pipes, Fittings, and Accessories for Water Pipelines — European Committee for Standardization (CEN)

- ISO 9001: Quality Management Systems — Requirements — International Organization for Standardization