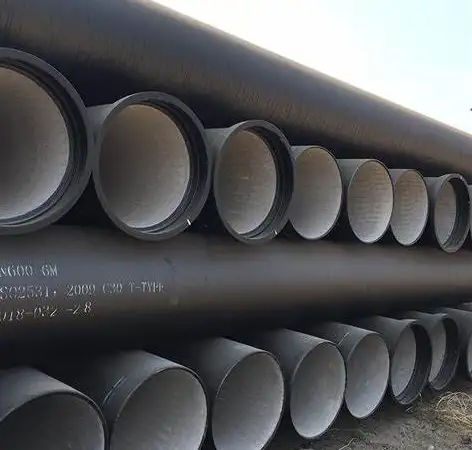

Ductile iron pipes are widely used in water supply, sewage systems, and industrial applications due to their durability and flexibility. One critical factor in designing these systems is understanding the standard length of ductile iron pipe, which affects installation efficiency, transportation costs, and project timelines.

Standard Length Ranges for Ductile Iron Pipe

Most manufacturers produce ductile iron pipes in standardized lengths to ensure compatibility with joint systems and installation equipment. Here are common length ranges:

| Pipe Diameter (mm) | Standard Length (meters) | Common Applications |

|---|---|---|

| 80–300 | 5.5–6.1 | Residential water supply |

| 350–600 | 5.5–6.1 | Municipal sewage systems |

| 700–1200 | 5.5–6.1 | Industrial pipelines |

| 1400–2600 | 5.0–5.5 | Large-scale water transport |

Note: Lengths may vary slightly depending on regional standards or manufacturer specifications.

Why Are Standard Lengths Important?

-

Cost Efficiency: Pre-cut lengths reduce on-site welding and labor costs.

-

Transportation: Optimized for truckload capacities (e.g., 6-meter pipes fit standard trailers).

-

Joint Compatibility: Designed to work with push-on joints, mechanical joints, or flanges.

Regional Variations in Pipe Length Standards

While 5.5–6.1 meters is the global norm, regional practices differ:

-

North America: Typically 5.5–6.1 meters (18–20 feet).

-

Europe: Often 5.8–6.0 meters (EN 545 standards).

-

Asia: Varies between 5.5–6.0 meters, with Japan favoring shorter 5.0-meter pipes for urban projects.

Factors Influencing Pipe Length Selection

-

Project Scale: Longer pipes reduce joints in large pipelines but require heavy machinery.

-

Terrain: Shorter pipes are preferred for hilly or congested areas.

-

Joint Type: Push-on joints accommodate minor length adjustments, while welded joints demand precision.

FAQ: Common Questions About Ductile Iron Pipe Lengths

Q1: Can ductile iron pipes be customized to non-standard lengths?

Yes. Manufacturers often cut pipes to custom lengths (e.g., 3 meters for repairs), but this may increase costs.

Q2: How does pipe length affect shipping?

Pipes over 6 meters may require special permits or vehicles, raising logistics expenses.

Q3: Are shorter pipes weaker than standard-length pipes?

No. Strength depends on wall thickness and material grade, not length.

Q4: What’s the maximum recommended length for underground installation?

6.1 meters is ideal for most cases. Excessively long pipes risk deflection during backfilling.

Case Study: Optimizing Pipe Length for a Water Supply Project

A municipal project in Germany saved 12% on labor costs by using 6-meter pipes with push-on joints, minimizing connections. However, a similar project in Tokyo opted for 5-meter pipes to navigate narrow streets.

Key Takeaways

-

The standard length of ductile iron pipe ranges from 5.5 to 6.1 meters, balancing practicality and performance.

-

Always check regional standards and consult manufacturers for project-specific requirements.

-

Proper length selection reduces installation time, leaks, and lifecycle costs.

References:

- Ductile Iron Pipe – Wikipedia

- ISO 2531:2009 – Ductile Iron Pipes and Fittings for Water Applications

- EN 545:2010 – Ductile Iron Pipes and Fittings for Water Pipelines

- Ductile Iron Pipe Specifications – DIPRA (Ductile Iron Pipe Research Association)

- AWWA C150 – Thickness Design of Ductile-Iron Pipe (American Water Works Association)