The outside diameter (OD) of a 4-inch ductile iron pipe (DIP) is 4.80 inches (121.92 mm) according to ANSI/AWWA C151 standards, which govern ductile iron pipe dimensions in North America. This standardized OD ensures compatibility with fittings, valves, and joint systems across municipal water, wastewater, and industrial networks.

1. Introduction to Ductile Iron Pipes

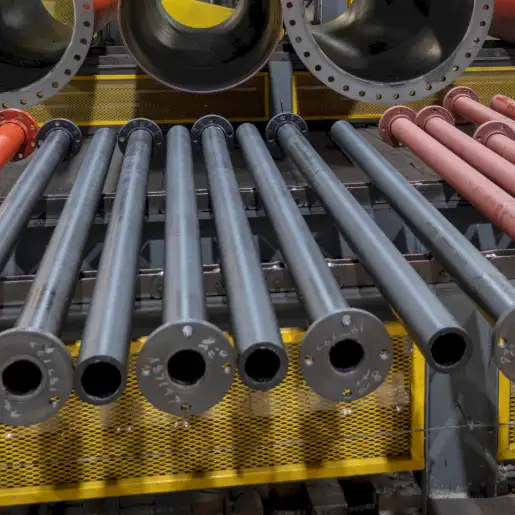

Ductile iron pipes are a modern evolution of traditional cast iron pipes, offering enhanced strength, flexibility, and durability. They are widely used in water and wastewater systems, as well as in industrial applications. The term “ductile” refers to the material’s ability to undergo significant deformation before failure, a property achieved through the addition of small amounts of magnesium during the casting process.

2. Understanding Pipe Dimensions

2.1 Nominal Pipe Size (NPS)

The nominal pipe size is a standardized designation used to identify pipe dimensions. For example, a 4-inch nominal pipe size refers to a pipe that is approximately 4 inches in internal diameter. However, the actual outside diameter (OD) and wall thickness can vary depending on the pipe material and manufacturing standards.

2.2 Outside Diameter (OD)

The outside diameter is the total external measurement of the pipe, including the wall thickness. This dimension is crucial for ensuring compatibility with fittings, flanges, and other components.

2.3 Wall Thickness

Wall thickness refers to the thickness of the pipe’s material. It influences the pipe’s pressure rating, weight, and overall strength.

3. Standard Dimensions for 4-Inch Ductile Iron Pipe

According to industry standards, the dimensions for a 4-inch ductile iron pipe are as follows:

-

Nominal Size: 4 inches

-

Outside Diameter (OD): 4.80 inches

-

Wall Thickness: Varies depending on the pressure class and lining type

These dimensions are standardized to ensure compatibility with various fittings and components.

4. Pressure Classes and Their Impact on Dimensions

Ductile iron pipes are manufactured in different pressure classes, which correspond to the pipe’s ability to withstand internal pressure. Common pressure classes include:

-

Class 52: Designed for a working pressure of 150 psi.

-

Class 54: Designed for a working pressure of 150 psi.

-

Class 56: Designed for a working pressure of 150 psi.

-

Class 56: Designed for a working pressure of 150 psi.

The wall thickness increases with the pressure class, affecting the pipe’s weight and external dimensions.

5. Comparison with Other Pipe Materials

| Pipe Material | Nominal Size | Outside Diameter (OD) | Wall Thickness | Pressure Class |

|---|---|---|---|---|

| Ductile Iron | 4 inches | 4.80 inches | Varies | Class 52 |

| PVC | 4 inches | 4.80 inches | Varies | SDR 21 |

| Steel | 4 inches | 4.50 inches | Varies | Schedule 40 |

This comparison highlights the differences in dimensions and pressure ratings among various pipe materials.

6. Applications of 4-Inch Ductile Iron Pipe

4-inch ductile iron pipes are commonly used in:

-

Water Distribution Systems: Transporting potable water to residential and commercial areas.

-

Sewer Systems: Carrying wastewater from homes and businesses to treatment facilities.

-

Industrial Applications: Serving as conduits for various industrial processes.

Their durability and strength make them suitable for both underground and above-ground installations.

7. Frequently Asked Questions (FAQs)

Q1: What is the significance of the 4.80-inch outside diameter for 4-inch ductile iron pipe?

A1: The 4.80-inch outside diameter ensures compatibility with standard fittings and flanges designed for ductile iron pipes. This standardization simplifies installation and maintenance processes.

Q2: How does the wall thickness affect the pipe’s performance?

A2: The wall thickness determines the pipe’s pressure rating and strength. Thicker walls allow the pipe to withstand higher internal pressures, making them suitable for specific applications.

Q3: Can the outside diameter vary for the same nominal size?

A3: Yes, the outside diameter can vary depending on the pipe material and manufacturing standards. For instance, PVC pipes may have a different OD compared to ductile iron pipes of the same nominal size.

Q4: What is the relationship between pressure class and wall thickness?

A4: Higher pressure classes require thicker walls to withstand increased internal pressures. For example, a Class 56 pipe will have a thicker wall than a Class 52 pipe of the same nominal size.

Q5: Are there international standards for ductile iron pipe dimensions?

A5: Yes, international standards such as ISO 2531 and EN 545/598 provide guidelines for ductile iron pipe dimensions. However, dimensions may vary slightly between different standards.

Q6: How does the outside diameter affect installation?

A6: The outside diameter is crucial for ensuring that the pipe fits properly with other components like fittings and valves. Standardizing the OD simplifies the procurement and installation processes.

8. Conclusion

Understanding the dimensions of a 4-inch ductile iron pipe, particularly its outside diameter, is essential for ensuring compatibility with other system components and for selecting the appropriate pipe for specific applications. By adhering to standardized dimensions, engineers and contractors can streamline installation processes and maintain system integrity.