Heat treatment processes are essential in metallurgy to modify the physical and mechanical properties of metals, particularly ferrous alloys. Among these processes, tempering and austempering are widely utilized to enhance the performance of steel and cast iron components. While both aim to improve toughness and reduce brittleness, they differ significantly in methodology, resulting microstructures, and applications.

Overview of Tempering

Tempering is a heat treatment process applied to quenched steel to reduce brittleness and relieve internal stresses. The process involves reheating the steel to a temperature below its eutectoid temperature (typically between 150°C and 650°C), holding it at that temperature for a specified duration, and then cooling it. This treatment allows for the formation of tempered martensite, which balances hardness and ductility.

Process Steps:

-

Heating: The quenched steel is reheated to a predetermined temperature below the eutectoid point.

-

Holding: The material is maintained at this temperature for a specified time to allow for the transformation of the microstructure.

-

Cooling: The steel is then cooled, typically in air, to room temperature.

Microstructure:

The resulting microstructure is tempered martensite, which exhibits improved toughness and reduced brittleness compared to as-quenched martensite.

Overview of Austempering

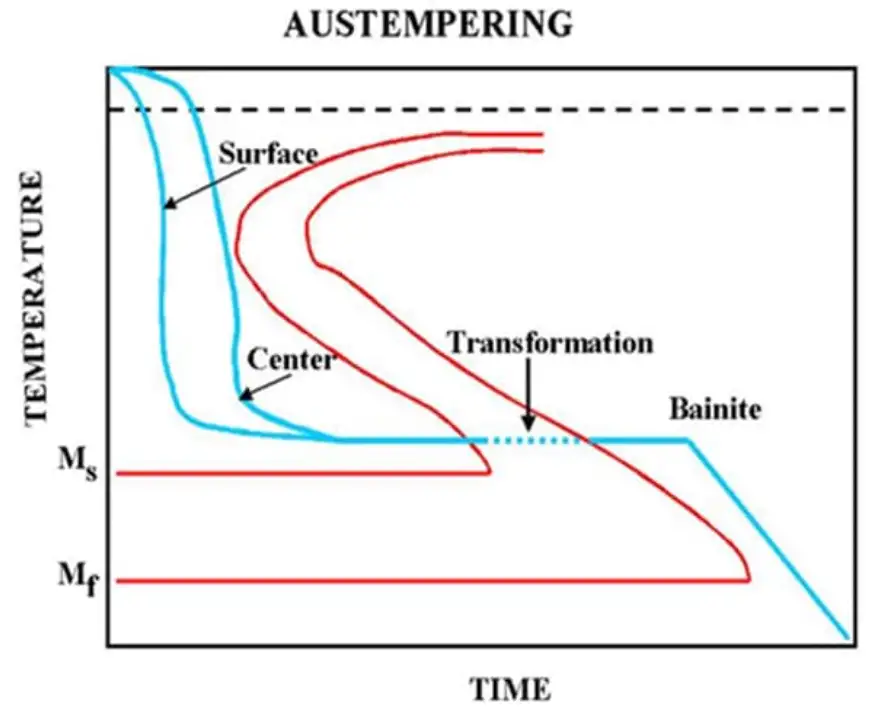

Austempering is an isothermal heat treatment process applied to ferrous alloys to produce a bainitic microstructure. The process involves heating the material to the austenitizing temperature, quenching it to a temperature above the martensite start (Ms) temperature, and holding it at this temperature for a specified time to allow for the transformation to bainite. This treatment results in improved strength and toughness without the need for subsequent tempering.

Process Steps:

-

Austenitizing: The material is heated to the austenitizing temperature, typically between 800°C and 900°C.

-

Quenching: The material is rapidly cooled to a temperature above the Ms temperature, usually between 250°C and 400°C.

-

Holding: The material is held at this temperature for a specified duration to allow for the transformation to bainite.

-

Cooling: The material is then cooled to room temperature.

Microstructure:

The resulting microstructure is bainite, which provides a combination of high strength and toughness.

Comparative Analysis: Tempering vs. Austempering

| Feature | Tempering | Austempering |

|---|---|---|

| Purpose | Reduce brittleness and relieve stresses | Achieve bainitic microstructure without subsequent tempering |

| Temperature Range | 150°C to 650°C | 250°C to 400°C |

| Cooling Rate | Slow (air cooling) | Rapid (quenching) |

| Final Microstructure | Tempered martensite | Bainite |

| Need for Subsequent Treatment | Yes (tempering required) | No (self-tempering) |

| Applications | Tools, springs, automotive components | Automotive gears, suspension parts |

Microstructural Differences

-

Tempered Martensite: Formed by reheating quenched martensite to a temperature below the eutectoid point, resulting in a microstructure that balances hardness and ductility.

-

Bainite: Formed by holding the material at a temperature above the Ms temperature, resulting in a microstructure that provides a combination of high strength and toughness.

Mechanical Property Comparison

| Property | Tempered Martensite | Bainite |

|---|---|---|

| Hardness | High | High |

| Toughness | Moderate | High |

| Wear Resistance | Good | Excellent |

| Distortion | Moderate | Low |

| Fatigue Resistance | Moderate | High |

Applications of Tempering and Austempering

Tempering:

-

Tools and Dies: To reduce brittleness and improve toughness.

-

Automotive Components: Such as gears and shafts, to enhance durability.

-

Springs: To achieve the desired balance between strength and ductility.

Austempering:

-

Automotive Gears: To achieve high strength and toughness without subsequent tempering.

-

Suspension Components: Such as control arms and spindles, to enhance performance.

-

Ductile Iron Castings: To produce components with improved mechanical properties.

Advantages and Limitations

Tempering:

Advantages:

-

Allows for precise control over hardness and toughness.

-

Widely applicable to various steel grades.

Limitations:

-

Requires additional processing steps, increasing time and cost.

-

May result in higher distortion compared to austempering.

Austempering:

Advantages:

-

Achieves desired mechanical properties without the need for subsequent tempering.

-

Reduces distortion and residual stresses.

Limitations:

-

Limited to specific alloy compositions.

-

Requires precise control of temperature and time.

Frequently Asked Questions (FAQs)

1. What is the primary difference between tempering and austempering?

The primary difference lies in the heat treatment process and resulting microstructure. Tempering involves reheating quenched steel to a temperature below the eutectoid point to reduce brittleness and relieve internal stresses, resulting in tempered martensite. Austempering, on the other hand, involves quenching the material to a temperature above the martensite start temperature and holding it at that temperature to form bainite, eliminating the need for subsequent tempering.

2. Can austempering be applied to all types of steel?

No, austempering is primarily applicable to medium-to-high carbon steels and ductile iron castings. Alloy compositions with sufficient hardenability are required to achieve the desired bainitic microstructure.

3. Does austempering eliminate the need for tempering?

Yes, austempering produces a bainitic microstructure that provides a balance of strength and toughness, eliminating the need for subsequent tempering.

4. What are the advantages of austempering over conventional quenching and tempering?

Austempering offers reduced distortion, improved fatigue resistance, and better wear resistance compared to conventional quenching and tempering. Additionally, it eliminates the need for a separate tempering step, streamlining the heat treatment process.

5. In what industries is austempering commonly used?

Austempering is commonly used in the automotive industry for components such as gears, suspension parts, and ductile iron castings that require high strength and toughness.

6. Are there any limitations to using austempering?

Yes, austempering requires precise control of temperature and time, and is limited to specific alloy compositions. Additionally, the process may not be suitable for components with complex geometries or large cross-sectional areas.

Conclusion

Both tempering and austempering are vital heat treatment processes that enhance the mechanical properties of ferrous alloys. While tempering is widely applicable and allows for precise control over hardness and toughness, austempering offers advantages in terms of reduced distortion and elimination of the need for subsequent tempering. The choice between the two processes depends on the specific requirements of the application, including material composition, desired properties, and manufacturing considerations.