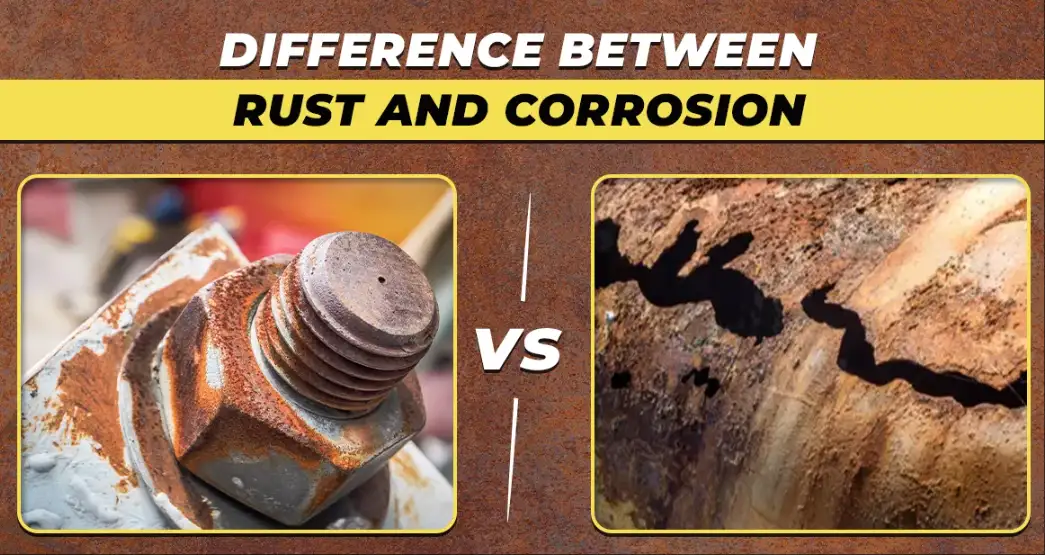

In the world of materials science and engineering, understanding the phenomena of rust and corrosion is crucial for maintaining the longevity and integrity of metal structures. While often used interchangeably, rust and corrosion are distinct processes with different implications for materials. This comprehensive guide delves into their differences, causes, effects, and prevention methods.

What is Corrosion?

Corrosion is a natural electrochemical process that leads to the deterioration of metals due to reactions with environmental elements such as oxygen, water, acids, or salts. It encompasses a wide range of reactions beyond just rust formation. Corrosion can affect various metals, including iron, aluminum, copper, and their alloys.

Types of Corrosion

-

Uniform Corrosion: Occurs evenly across the surface of the metal, leading to a gradual thinning of the material.

-

Pitting Corrosion: Localized corrosion that leads to the formation of small pits or holes on the metal surface.

-

Galvanic Corrosion: Happens when two dissimilar metals are in electrical contact in the presence of an electrolyte, causing one metal to corrode faster than the other.

-

Crevice Corrosion: Occurs in confined spaces where the access of the working fluid is limited, leading to localized corrosion.

-

Intergranular Corrosion: Takes place along the grain boundaries of a metal, often due to impurities or alloying elements.

What is Rust?

Rust is a specific type of corrosion that occurs when iron or its alloys, such as steel, react with oxygen and moisture over time. The chemical reaction produces iron oxides, commonly known as rust, which typically appears as a reddish-brown flaky substance on the metal surface.

Chemical Reaction of Rust Formation

The formation of rust involves several electrochemical reactions:

-

Oxidation at the Anode: Iron (Fe) loses electrons to form iron ions (Fe²⁺).

-

Reduction at the Cathode: Oxygen (O₂) and water (H₂O) gain electrons to form hydroxide ions (OH⁻).

-

Formation of Iron Hydroxide: Iron ions (Fe²⁺) react with hydroxide ions (OH⁻) to form iron(II) hydroxide.

-

Oxidation to Iron Oxide: Iron(II) hydroxide is further oxidized to form iron(III) oxide, commonly known as rust.

This process is accelerated in the presence of electrolytes like saltwater, which facilitate the movement of ions.

Key Differences Between Rust and Corrosion

| Aspect | Corrosion | Rust |

|---|---|---|

| Definition | General term for metal deterioration | Specific type of corrosion affecting iron |

| Occurrence | Affects various metals | Primarily affects iron and its alloys |

| Appearance | Varies (e.g., tarnish on silver, patina on copper) | Reddish-brown flaky substance |

| Protective Layer | Some forms can form protective oxide layers | No protective layer; accelerates further corrosion |

| Electrochemical Process | Involves electron transfer reactions | Involves specific reactions leading to iron oxides |

Causes of Rust and Corrosion

Environmental Factors

-

Moisture: Water is a key component in both rust and corrosion processes.

-

Oxygen: Essential for the formation of oxides in corrosion and rust.

-

Salts: Presence of salts, especially in marine environments, accelerates corrosion.

-

Acids: Acidic conditions can lead to aggressive corrosion of metals.

Material Factors

-

Alloy Composition: Metals with certain alloying elements may corrode differently.

-

Surface Finish: Rough or damaged surfaces are more susceptible to corrosion.

-

Protective Coatings: Lack of protective coatings increases vulnerability to corrosion.

Effects of Rust and Corrosion

Structural Integrity

Both rust and corrosion compromise the strength and stability of metal structures, leading to potential failures in bridges, pipelines, and machinery.

Economic Impact

The cost of repairing or replacing corroded components is substantial, affecting industries globally. For instance, the U.S. Department of Defense spends approximately $23 billion annually on corrosion-related issues .

Environmental Concerns

Corrosion can lead to environmental contamination, especially when hazardous materials leak from corroded containers or pipelines.

Prevention Methods

Protective Coatings

Applying paints, galvanization, or other coatings can shield metals from environmental factors.

Cathodic Protection

Attaching a more anodic material (like zinc) to the metal structure can prevent corrosion by sacrificing itself.

Environmental Control

Reducing exposure to moisture, oxygen, and corrosive agents can minimize corrosion risks.

Material Selection

Choosing corrosion-resistant materials or alloys can enhance longevity.

Frequently Asked Questions (FAQs)

1. Is all corrosion rust?

No, not all corrosion is rust. Rust specifically refers to the corrosion of iron and its alloys. Other metals undergo different corrosion processes, such as tarnishing in silver or patina formation in copper .

2. Can rust be prevented?

Yes, rust can be prevented by applying protective coatings, using corrosion-resistant materials, and employing methods like cathodic protection .

3. What is the role of salt in corrosion?

Salt acts as an electrolyte, facilitating the movement of ions and accelerating the corrosion process, especially in marine environments.

4. How does corrosion affect infrastructure?

Corrosion can weaken structural components, leading to failures in bridges, pipelines, and buildings, posing safety risks and incurring significant repair costs.

5. Are there eco-friendly methods to combat corrosion?

Yes, eco-friendly methods include using biodegradable inhibitors, applying non-toxic coatings, and employing green technologies for corrosion prevention.

Conclusion

Understanding the differences between rust and corrosion is essential for effectively managing and preventing metal deterioration. While rust is a specific type of corrosion affecting iron, corrosion encompasses a broader range of reactions impacting various metals. By implementing appropriate prevention strategies, the adverse effects of these processes can be mitigated, ensuring the longevity and safety of metal structures.