When designing and installing pipeline systems, the type of joint used to connect the pipes is critical for ensuring a secure, leak-proof, and long-lasting system. Two common types of joints used in these systems are restrained joints and mechanical joints. Both offer unique advantages, but understanding their differences is essential for selecting the right option for a specific application.

In this article, we will thoroughly compare restrained joints and mechanical joints, exploring their features, installation processes, benefits, and challenges. Additionally, we will provide a detailed comparison table, answer common questions, and highlight the best use cases for each type of joint.

1. What Are Restrained Joints?

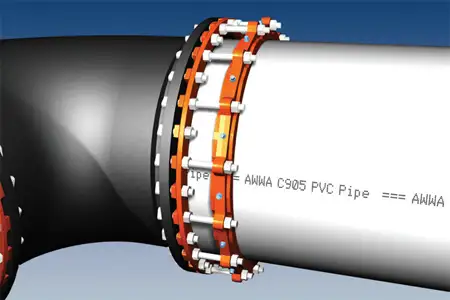

A restrained joint is a type of pipe joint that incorporates a mechanism to prevent the pipe from moving or separating under pressure. These joints use a combination of mechanical devices such as restraint rings, locking devices, or clamps to hold the pipe sections together securely.

Key Features of Restrained Joints:

-

Pressure Resistance: Designed to handle high-pressure systems, restrained joints provide additional stability and prevent separation.

-

No Need for Thrust Blocks: Unlike other types of joints, restrained joints do not require external thrust blocks or anchors to prevent movement.

-

Durability: These joints are designed to last for decades and withstand external forces such as soil movement or seismic activity.

Applications of Restrained Joints:

-

Water and Wastewater Systems: Ideal for systems that require high-pressure ratings, such as water distribution networks and sewage pipelines.

-

Fire Suppression Systems: Often used in fire suppression systems that demand high-pressure handling.

-

Industrial Applications: Suitable for industries that require robust and secure pipe systems for the transport of fluids.

2. What Are Mechanical Joints?

A mechanical joint is a pipe connection that utilizes a series of bolts, nuts, gaskets, and sleeves to form a secure, leak-proof seal. Unlike restrained joints, mechanical joints rely on the compression of the gasket and the tightening of bolts to hold the pipe sections together.

Key Features of Mechanical Joints:

-

Simple Installation: Mechanical joints are easier to install than restrained joints and require fewer specialized tools.

-

Flexibility: They allow for some degree of flexibility, making them suitable for pipe systems that may need to accommodate slight movements or changes in alignment.

-

Cost-Effective: Generally, mechanical joints are less expensive than restrained joints, making them a popular choice for low-pressure systems or temporary installations.

Applications of Mechanical Joints:

-

Low-Pressure Systems: Ideal for systems that do not face extreme pressure or forces, such as irrigation or drainage systems.

-

Residential and Commercial Projects: Often used in smaller projects where budget and ease of installation are primary concerns.

-

Temporary Installations: Due to their ease of disassembly, mechanical joints are often used in systems that need to be taken apart or modified.

3. Comparison of Restrained Joint vs Mechanical Joint

The following table provides a side-by-side comparison of restrained joints and mechanical joints, highlighting their features, benefits, and ideal applications.

| Feature | Restrained Joint | Mechanical Joint |

|---|---|---|

| Connection Method | Uses restraint mechanisms like rings or clamps | Uses bolts, nuts, and gaskets |

| Pressure Handling | Suitable for high-pressure systems | Best for low to medium-pressure systems |

| Durability | Very durable, can last decades without issues | Less durable under high-pressure or heavy load |

| Installation Complexity | More complex, requires special tools | Easier and faster to install |

| Flexibility | Rigid, no movement between pipes | Some flexibility, can accommodate minor shifts |

| Cost | More expensive due to the complexity | More cost-effective |

| Use Case | Water, wastewater, and industrial pipelines | Low-pressure systems, temporary installations |

| Maintenance | Low maintenance required once installed | May require more frequent maintenance |

| Strength | Extremely strong and resistant to forces | Less strength under heavy external forces |

4. Advantages of Restrained Joints

Restrained joints offer a range of advantages that make them ideal for specific applications. Here are some key benefits:

4.1. High-Pressure Resistance

Restrained joints are engineered to withstand higher pressure ratings compared to mechanical joints. This makes them suitable for critical applications like municipal water systems, fire suppression, and industrial fluid transport, where maintaining system integrity under high pressure is paramount.

4.2. Enhanced Safety

By preventing the separation of pipe sections under pressure, restrained joints improve the overall safety of the pipeline system. This is especially important in areas where pipeline failure could lead to significant damage or hazards, such as industrial sites or heavily populated areas.

4.3. Long-Term Durability

The combination of robust materials and design features ensures that restrained joints have a longer lifespan compared to mechanical joints. Their resistance to corrosion, pressure surges, and environmental factors makes them a preferred choice for critical infrastructure.

5. Advantages of Mechanical Joints

Mechanical joints also provide a number of advantages, particularly in less demanding applications:

5.1. Easy Installation and Maintenance

Mechanical joints are simpler to install, requiring fewer tools and less specialized knowledge. Additionally, they are easier to disassemble for maintenance or repairs, making them ideal for systems that may need modifications or upgrades over time.

5.2. Cost-Effective

Mechanical joints are typically less expensive than restrained joints, making them an attractive choice for lower-budget projects or systems where high-pressure resistance is not required.

5.3. Flexibility

Mechanical joints offer a certain degree of flexibility, allowing the pipes to shift slightly due to ground movements, thermal expansion, or slight misalignment during installation. This can be an advantage in areas where pipe movement is anticipated.

6. Frequently Asked Questions (FAQs)

1. What is the main difference between a restrained joint and a mechanical joint?

The primary difference lies in the method of securing the pipe sections. A restrained joint uses restraint mechanisms such as rings or clamps to prevent movement under pressure, whereas a mechanical joint relies on the compression of a gasket and the tightening of bolts for a leak-proof seal.

2. Which type of joint is better for high-pressure systems?

Restrained joints are better suited for high-pressure systems because they are designed to resist pressure surges and prevent pipe separation. Mechanical joints, on the other hand, are typically used for lower-pressure applications.

3. Are restrained joints more expensive than mechanical joints?

Yes, restrained joints are generally more expensive due to the complexity of the design and materials involved. They are often used in more demanding applications where durability and pressure resistance are critical.

4. Can mechanical joints be used in water distribution systems?

Mechanical joints can be used in water distribution systems, but they are typically reserved for lower-pressure systems. For high-pressure applications, restrained joints are the preferred choice.

5. How do I decide between using a restrained joint or a mechanical joint?

The choice depends on several factors, including the pressure rating of the system, the required durability, installation complexity, and budget. For high-pressure or critical systems, restrained joints are recommended, while mechanical joints are suitable for low-pressure, less demanding applications.

Conclusion

Choosing between restrained joints and mechanical joints depends on the specific needs of your pipeline system. Restrained joints provide superior pressure resistance and durability, making them ideal for high-pressure, industrial, and municipal applications. Mechanical joints, on the other hand, offer cost savings, ease of installation, and flexibility, making them a good choice for low-pressure systems or temporary installations.