In the realm of pipeline construction and infrastructure, one of the critical decisions that engineers and contractors must make is the type of joint to use for connecting pipes. Restrained and unrestrained joints are two common options, each with distinct characteristics that affect their performance, durability, and applications.

Whether you’re working on water distribution systems, wastewater systems, or industrial piping, understanding the key differences between these two joint types can have a significant impact on the project’s overall efficiency, longevity, and cost. This article will explore both types of joints in-depth, helping you choose the right option for your specific needs.

We’ll cover everything from their design, benefits, and installation processes, to their suitability for various applications. Additionally, we’ll provide a comparison table and answer some of the most frequently asked questions about restrained and unrestrained joints.

1. What Are Restrained Joints?

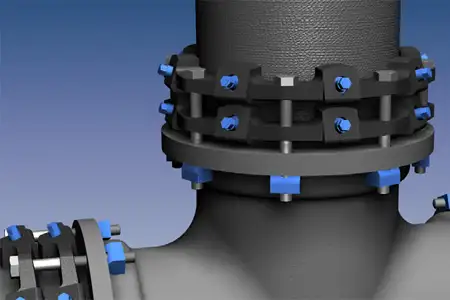

A restrained joint is a type of pipe joint designed to resist the axial movement of the pipe. This is achieved using mechanical devices like restraint rings, clamps, or locking systems, which prevent the pipe from separating under pressure or external forces. Restrained joints are commonly used in high-pressure systems or applications where the pipeline is exposed to significant external forces.

Key Features of Restrained Joints:

-

Pressure Resistance: Restrained joints are capable of withstanding high internal pressure, making them ideal for systems such as water supply networks, sewage systems, and fire protection systems.

-

No Thrust Blocks: One of the most notable benefits of restrained joints is that they don’t require external thrust blocks, which are typically needed for unrestrained joints to prevent pipe movement.

-

Durability: These joints are highly durable and designed to handle harsh environmental conditions and external stresses.

-

Maintenance: Restrained joints are low maintenance due to their robust construction, which ensures a secure, long-lasting connection.

Applications of Restrained Joints:

-

Water and Wastewater Systems: Used extensively in municipal water supply and sewer systems, where high-pressure and long-term durability are essential.

-

Fire Suppression Systems: These joints are common in fire safety applications, where they must handle high water pressure.

-

Industrial Systems: Restrained joints are often used in industries that require secure connections for the transportation of fluids under high pressure.

2. What Are Unrestrained Joints?

In contrast, unrestrained joints are designed to allow for axial movement in the pipe. These joints rely on the sealing ability of gaskets or compression fittings to create a secure connection. Unrestrained joints do not have the same mechanical locking systems as restrained joints, making them less suited for high-pressure applications where pipe movement must be controlled.

Key Features of Unrestrained Joints:

-

Simpler Design: Unrestrained joints have a simpler construction compared to restrained joints, making them easier and quicker to install.

-

Flexibility: These joints allow some movement between the pipes, which can be useful in systems that may experience slight shifts or thermal expansion.

-

Cost-Effective: Typically, unrestrained joints are less expensive than restrained joints, making them ideal for low-budget projects or systems that do not face high internal pressures.

-

Dependence on Thrust Blocks: To prevent the separation of pipes under pressure, unrestrained joints require external thrust blocks, which add to the overall installation complexity.

Applications of Unrestrained Joints:

-

Low-Pressure Systems: Unrestrained joints are suitable for low-pressure pipelines, such as irrigation or drainage systems, where pipe movement is not a concern.

-

Temporary Installations: Often used in temporary pipeline setups, where disassembly or modification is needed.

-

Residential Projects: Common in residential plumbing systems, where pipes are not subjected to extreme forces.

3. Comparison Between Restrained and Unrestrained Joints

The table below highlights the key differences between restrained and unrestrained joints. This side-by-side comparison will help you better understand when to use each type of joint.

| Feature | Restrained Joints | Unrestrained Joints |

|---|---|---|

| Pipe Movement Control | Prevents axial movement of pipes | Allows for axial movement between pipes |

| Pressure Handling | High-pressure systems | Best for low-pressure systems |

| Flexibility | Rigid, no flexibility | Allows for slight flexibility and movement |

| Installation Complexity | More complex, requires special tools | Easier to install with fewer tools required |

| Durability | Extremely durable, resistant to external forces | Less durable, vulnerable to separation under pressure |

| Cost | More expensive due to complex design | More cost-effective, ideal for low-budget projects |

| Thrust Blocks | No need for thrust blocks | Requires external thrust blocks for pipe stability |

| Maintenance | Low maintenance, long-lasting connections | Higher maintenance needs due to reliance on thrust blocks |

4. Advantages of Restrained Joints

4.1. High-Pressure Resistance

One of the primary advantages of restrained joints is their ability to withstand high internal pressure. This makes them perfect for water distribution systems, fire suppression, and other industrial applications where maintaining pressure is critical.

4.2. Increased Safety

By preventing pipe movement, restrained joints reduce the risk of pipe separation under pressure, which can lead to system failure or even catastrophic damage.

4.3. Longer Lifespan

Restrained joints are highly durable and designed to last for decades with minimal maintenance. They are less susceptible to wear and tear, making them ideal for long-term infrastructure projects.

5. Advantages of Unrestrained Joints

5.1. Lower Installation Costs

Unrestrained joints are more affordable, making them an attractive option for projects on a budget. Their simplicity and ease of installation make them ideal for smaller-scale projects or low-pressure systems.

5.2. Easier to Disassemble

Since they do not rely on mechanical locking systems, unrestrained joints are easier to disassemble and modify, making them suitable for temporary or adaptable installations.

5.3. Flexibility

Unrestrained joints can accommodate slight shifts or movements in the pipeline, making them suitable for installations where ground movement or temperature fluctuations might occur.

6. Frequently Asked Questions (FAQs)

1. What is the primary difference between restrained and unrestrained joints?

The main difference between restrained and unrestrained joints lies in the ability to resist pipe movement. Restrained joints use mechanical systems to prevent the pipe from moving, while unrestrained joints allow for some movement between the pipes. Restrained joints are suitable for high-pressure systems, whereas unrestrained joints are used for lower-pressure applications where flexibility and movement are not a concern.

2. Are restrained joints more expensive than unrestrained joints?

Yes, restrained joints are generally more expensive than unrestrained joints due to their complex design and the additional materials required for pipe restraint. The added cost comes with the benefit of superior pressure resistance and durability, which makes them suitable for critical systems such as water distribution and fire suppression networks.

3. Can unrestrained joints be used in high-pressure systems?

Unrestrained joints are typically not recommended for high-pressure systems. While they are cost-effective and easier to install, they cannot handle the high internal pressure without the risk of pipe separation. For high-pressure systems, restrained joints are the preferred choice because they can handle greater forces and provide a more secure connection.

4. Do unrestrained joints require maintenance?

Yes, unrestrained joints generally require more maintenance compared to restrained joints. Since they rely on external thrust blocks to prevent pipe movement, these blocks need to be checked regularly for any signs of displacement or failure. In contrast, restrained joints are less prone to such issues and typically require less maintenance.

5. In what types of projects are unrestrained joints most suitable?

Unrestrained joints are most suitable for low-pressure systems, such as residential plumbing, drainage systems, and irrigation. They are also ideal for temporary installations or systems that do not require high-pressure resistance. Their affordability and ease of installation make them a good choice for smaller projects or projects with a limited budget.

Conclusion

In conclusion, both restrained and unrestrained joints have their unique advantages and are suited to different types of projects. Restrained joints provide superior pressure resistance, durability, and safety, making them ideal for high-pressure systems and long-term infrastructure projects. On the other hand, unrestrained joints are more cost-effective, easier to install, and suitable for low-pressure applications or temporary systems.