When it comes to pipe fittings and connections, understanding the different types of threads is essential for ensuring proper functionality, compatibility, and safety. Two common thread types used in piping systems are NPT (National Pipe Thread) and AWWA (American Water Works Association) threads. Each thread standard has specific applications and characteristics that make it suitable for different environments and uses. In this article, we will explore the differences between NPT and AWWA threads, including their design, applications, advantages, and disadvantages, to help you make an informed decision when selecting thread types for your projects.

1. Understanding NPT Threads

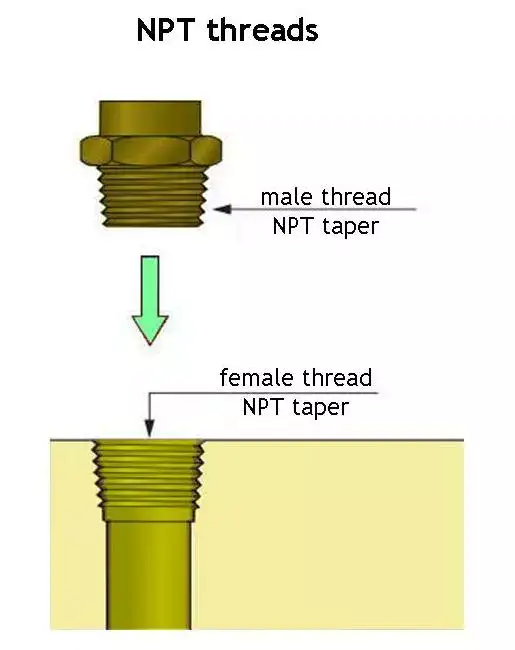

National Pipe Thread (NPT) is a widely used thread standard in the United States for joining pipes and fittings. NPT threads are designed for tapered threads that create a seal when tightened, providing a leak-free connection. They are used in many industries, including plumbing, oil and gas, and manufacturing.

Key Features of NPT Threads:

-

Tapered Design: NPT threads are tapered, meaning that the diameter of the thread decreases as it moves toward the end of the pipe. This allows for a tight, leak-resistant seal when the threads are tightened.

-

Seal Mechanism: The tight fit and tapered design create a mechanical seal between the male and female threads, which is enhanced when sealing compounds like thread sealant tape are used.

-

Standardization: NPT threads are standardized by ANSI (American National Standards Institute) and ASTM (American Society for Testing and Materials).

-

Common Uses: NPT threads are used in a wide range of applications, including plumbing systems, hydraulic fittings, compressors, and steam lines.

2. Understanding AWWA Threads

American Water Works Association (AWWA) threads are primarily used in water distribution systems and fittings. AWWA threads are non-tapered, designed specifically for waterworks and municipal applications. The AWWA thread standard governs many different types of pipe fittings, including flanges, valves, and hydrants.

Key Features of AWWA Threads:

-

Non-Tapered Design: AWWA threads are straight or parallel threads, unlike NPT’s tapered threads. This design ensures that the connection is made by the physical engagement of the threads rather than the creation of a seal through tightening.

-

Standardization: AWWA threads are also standardized by the American Water Works Association, which sets guidelines for water infrastructure.

-

Seal Enhancement: AWWA threads rely on sealing elements, such as rubber gaskets or O-rings, to create a leak-proof connection rather than depending on the tightness of the threads themselves.

-

Common Uses: AWWA threads are typically found in water supply systems, fire protection systems, sewer systems, and municipal water infrastructure.

3. Key Differences Between NPT and AWWA Threads

| Feature | NPT Threads | AWWA Threads |

|---|---|---|

| Thread Type | Tapered threads | Parallel threads |

| Sealing Mechanism | Mechanical seal via tight fit and thread tape | Seals are created by O-rings or gaskets |

| Standardization | ANSI/ASTM standards | AWWA standards |

| Primary Application | Plumbing, industrial, gas, hydraulic systems | Water distribution, fire hydrants, municipal systems |

| Usage | Requires thread sealant for leak prevention | Requires gasket or O-ring for sealing |

| Thread Profile | Tapered, conical shape | Straight, uniform diameter |

| Material Compatibility | Commonly used with metal pipes and fittings | Commonly used with cast iron, ductile iron, and steel |

| Pressure Handling | Suitable for moderate to high-pressure applications | Best for low to moderate pressure systems |

4. When to Use NPT Threads

NPT threads are best suited for applications where a secure, leak-free connection is essential, and where the use of sealants like PTFE tape or pipe dope is an option. These include:

-

Gas lines: NPT threads are ideal for gas applications due to the need for a strong seal.

-

Hydraulic systems: They are commonly used in high-pressure hydraulic lines, where a tight seal is crucial for safe operation.

-

Steam pipes: NPT threads can withstand the heat and pressure of steam lines, where leakage is not an option.

Advantages of NPT Threads:

-

Tight seals: The tapered design provides a strong, leak-resistant seal.

-

Versatility: NPT threads can be used with a wide variety of materials, including metals, plastics, and composites.

-

Widely used: Due to their common use in many industries, NPT threads are easily available and compatible with a variety of fittings and accessories.

Disadvantages of NPT Threads:

-

Requires sealant: NPT threads depend on sealants like PTFE tape or pipe dope to achieve a leak-proof seal, which can be messy and time-consuming.

-

Potential for cross-threading: If not properly aligned, NPT threads can be prone to cross-threading, which can lead to damage and leaks.

5. When to Use AWWA Threads

AWWA threads are more specialized and are best suited for waterworks and municipal applications. These are typically found in:

-

Water distribution systems: AWWA threads are ideal for connecting pipes and fittings in public water systems.

-

Fire hydrants: Fire hydrants often use AWWA threads to ensure secure connections to water mains.

-

Sewer systems: AWWA threads are commonly used in sewer infrastructure, particularly in fittings and valves.

Advantages of AWWA Threads:

-

No sealant required: AWWA threads rely on gaskets or O-rings to create a seal, reducing the need for messy sealants.

-

Durable: AWWA threads are designed to handle the unique demands of municipal water systems and are built to last.

-

Widely accepted in municipal systems: AWWA threads are a standard for waterworks applications, making them compatible with many different fittings and systems.

Disadvantages of AWWA Threads:

-

Not suitable for high-pressure applications: AWWA threads are generally not designed for high-pressure systems, as they rely on external sealing elements.

-

Limited versatility: AWWA threads are less commonly used outside of waterworks and municipal systems, making them less versatile than NPT threads in other industries.

6. Common FAQs about NPT and AWWA Threads

Q1: Can NPT and AWWA threads be used interchangeably?

No, NPT and AWWA threads are not interchangeable due to their different thread profiles and sealing mechanisms. NPT threads are tapered and require sealant, while AWWA threads are parallel and rely on gaskets or O-rings to seal.

Q2: What materials can be used with NPT threads?

NPT threads can be used with a wide variety of materials, including steel, brass, copper, plastic, and cast iron. The thread type is highly versatile, making it suitable for many different applications.

Q3: Are AWWA threads compatible with high-pressure systems?

No, AWWA threads are designed for low to moderate pressure systems, particularly in waterworks and municipal applications. For high-pressure systems, NPT threads are generally preferred due to their tapered design and tight seal.

Q4: Do AWWA threads require sealing compounds?

No, AWWA threads typically do not require sealing compounds. Instead, they use gaskets or O-rings to create a leak-proof seal. This makes installation easier and cleaner compared to NPT threads.

Q5: How can I tell if I need NPT or AWWA threads for my project?

The choice between NPT and AWWA threads depends on your application. If you are working with a water distribution system, fire hydrants, or sewer infrastructure, AWWA threads are likely the best option. For industrial applications requiring a tight, leak-proof seal, such as gas or hydraulic systems, NPT threads are typically preferred.

Q6: Can AWWA threads be used for non-water applications?

AWWA threads are primarily designed for waterworks and municipal applications, so they may not be the best choice for industrial or high-pressure systems. However, some water-related systems, such as fire suppression systems, may use AWWA threads for connections.

Conclusion

Understanding the differences between NPT and AWWA threads is crucial for selecting the right fitting for your specific application. NPT threads are ideal for industrial and high-pressure applications, while AWWA threads are more suitable for waterworks and municipal systems. By knowing when and where to use each thread type, engineers, contractors, and maintenance personnel can ensure that their piping systems are secure, durable, and leak-free.