Butterfly valves come in a wide range of diameters—from small ½″ (12 mm) valves for laboratory use up to massive 96″ (2 400 mm) valves for water mains and process piping. Their nominal diameter (DN or NPS) corresponds to the pipe size they connect to, defined by standards such as ANSI/ASME B16.5, EN 1092-1, and ISO 5752. Valve face-to-face and end-to-end dimensions vary by type (wafer, lug, flanged, double-flanged) and by standard (API 609, EN 593, AWWA C516), but nominal diameter remains the key metric for selection and installation. Correct diameter selection ensures proper flow capacity (Cv/Kv), minimal pressure drop, and compatibility with mating flanges or pipe ends.

I. Defining Valve Diameter

The diameter of a butterfly valve refers to the nominal bore—i.e., the inside diameter of the disc passage—which matches the pipe’s nominal diameter (NPS in inches or DN in millimeters). This nominal size defines the valve’s compatibility with piping systems: a 6″ butterfly valve has an internal passage roughly 6″ (150 mm) across.

Unlike some valves whose bodies may be larger than their bore (e.g., gate valves), butterfly valves maintain a slim profile: the disc rotates within the pipe bore, so the valve’s external dimensions can be only slightly larger than the nominal diameter.

Manufacturers label valves by this nominal diameter, but standardized face-to-face and end-to-end dimensions come from tables in ANSI B16.10, EN 558, API 609, etc., ensuring interchangeability across brands.

II. Standard Nominal Sizes & Ranges

Butterfly valves are produced in a broad span of nominal sizes:

-

Small-bore: ½″–2″ (DN 15–50 mm), typical for instrumentation and HVAC controls.

-

Medium-bore: 2″–24″ (DN 50–600 mm), the most common range for water, wastewater, and process industries.

-

Large-bore: 24″–96″ (DN 600–2400 mm), used in large water mains, power plants, and mining applications.

| Nominal Size (NPS) | DN (mm) | Typical Use Cases |

|---|---|---|

| ½″–2″ | 15–50 | Laboratory, HVAC, chemical dosing |

| 2″–12″ | 50–300 | Potable water, wastewater, HVAC |

| 14″–24″ | 350–600 | Fire protection, industrial process piping |

| 30″–96″ | 800–2400 | Water mains, hydroelectric, dredging systems |

Table 1. Common butterfly valve nominal sizes and DN equivalents.

III. Face-to-Face & End-to-End Dimensions

While nominal diameter defines the bore, face-to-face (F-F) and end-to-end (E-E) dimensions dictate the valve’s axial length, critical for piping layout:

| Standard | Type | F-F / E-E Dimension Reference |

|---|---|---|

| API 609 | Wafer / Lug | Table 5, EN 558 Cat A/B |

| ANSI B16.10 | Flanged | MSS SP-67 / 68 |

| EN 558-1 | Wafer (short pattern) | Series 15 (F-F 44 mm for DN 50) |

| AWWA C516 | Mechanical Joint | See brochure for 3″–20″ valves |

For example, a 6″ lug-type butterfly valve under EN 558-1 Series 15 has an F-F length of 65 mm, whereas in ISO 5752 table 5 it’s 63 mm. Always confirm your standard and series when designing a piping spool.

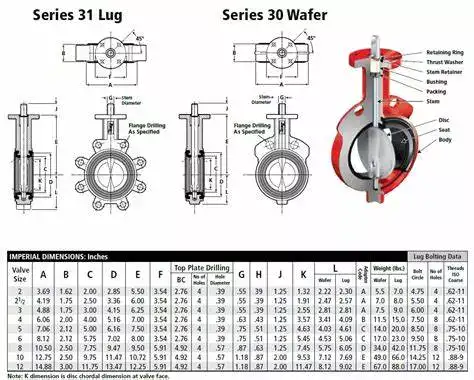

IV. Comparison by Valve Type

Wafer Style

-

Clamped between flanges using flange bolts; minimal F-F length.

-

F-F: Series 15 short or Series 20 long patterns.

-

Best for: Low-pressure, space-restricted installations.

Lug Style

-

Threaded lugs on body allow one-side removal.

-

F-F: Identical to wafer in EN 558, but with lugs.

-

Best for: Dead-end services where downstream removal is needed.

Double-Flanged

-

Flanged ends for full bolting on both sides.

-

F-F: per ANSI B16.10.

-

Best for: High-pressure and heavy industrial uses.

| Feature | Wafer | Lug | Double-Flanged |

|---|---|---|---|

| F-F Length | Shortest | Same as wafer | Longest |

| Removal | Must unbolt both sides | Downstream side only | Full flange removal |

| Pressure Rating | Up to 16 bar | Up to 16 bar | Up to 25 bar |

Table 2. Butterfly valve types compared.

V. Selecting the Right Diameter for Flow & Pressure

Valve diameter impacts flow coefficient (Cv/Kv), pressure drop, and flow control precision:

-

Full-opening butterfly valves approximate a straight-through pipe when fully open; Cv increases rapidly with diameter.

-

Undersizing leads to excessive velocity, noise, and erosion; oversizing reduces control resolution near closed position.

Sizing procedure:

-

Determine required flow rate (Q) and allowable pressure drop (ΔP).

-

Use valve Cv curves (provided by manufacturer) to find diameter where Cv ≈ Q/√ΔP.

-

Check diameter against available standard sizes.

Example: To pass 500 m³/h of water with ΔP = 0.3 bar, a 12″ valve (Cv ≈ 3 000) is appropriate; an 8″ (Cv ≈ 1 200) would generate too high a ΔP.

VI. Installation & Sizing Best Practices

-

Spacer or companion flange: For wafer valves, use spacers to avoid stressing flanges.

-

Alignment: Center valve disc at 60° open when bolting flanges to prevent disc flange contact.

-

Torque: Follow bolt torque recommendations—avoid over-compression of liner.

-

Bypass: For large diameters (> 24″), install bypass lines to avoid deadband at low flows.

Proper installation preserves face-to-face dimensions and ensures the valve performs to its rated diameter.

VII. Material & Pressure Class Impacts on Diameter

Valve body and liner materials can slightly alter internal bore dimensions:

-

Rubber-lined valves may have an internal diameter 1–2 mm smaller than nominal due to liner thickness.

-

Metal-seat and triple-offset valves maintain true bore but have heavier bodies, affecting external dimensions only.

-

Pressure class: Higher-class valves (300 lb/PN 40) often require larger wall thickness, marginally reducing effective bore.

Always check the manufacturer’s “bore chart” for the as-built I.D. when precise diameter is critical.

YouTube Video Tutorial

*How to measure and verify butterfly valve diameter and face-to-face dimensions in the field.*

Six Common Questions

1. How is butterfly valve diameter measured in the field?

To measure a valve’s diameter in situ:

-

Remove lug nuts on one side (lug style) or unbolt both flanges (wafer style).

-

Insert a straightedge across the bore; mark inside edges.

-

Measure between marks with a calibrated tape or calipers.

-

Verify against flange ID on companion flanges per ANSI/ASME or EN standards.

This direct method yields the as-installed bore, which may differ slightly from nominal size due to liner wear or manufacturing tolerances.

2. Can I install a butterfly valve in a larger piping system by using reducers?

Yes—use concentric or eccentric reducers upstream and downstream to match the valve’s nominal diameter. Ensure:

-

The piping enters/exits the valve with smooth transitions to avoid turbulence.

-

Reducers are rated for the same pressure class as the valve.

-

Face-to-face dimensions remain within design allowances; adjust spool pieces as needed.

Reducers allow using standard-sized valves in atypical pipe networks without needing custom valve sizes.

3. Why does a 24″ butterfly valve sometimes have a smaller actual bore?

Rubber lining and disc geometry reduce the true open I.D. by the combined thickness of the liner on both sides (often 2–4 mm total). In chemical-resistant lined valves, liners can be 3–5 mm thick per side, shrinking the flow-area diameter by 6–10 mm overall.

4. What standards govern butterfly valve diameter tolerances?

Key standards for tolerances include:

-

ANSI/ASME B16.5 & B16.10 for flanged valves (± 1.5% of nominal diameter).

-

EN 558-1 for wafer and lug types (± 1 mm for DN ≤ 200; ± 1.5 mm for DN > 200).

-

ISO 5752 table 5 (short pattern) and table 13 (long pattern) specify ± 1% tolerances.

These tolerances ensure mating flange alignment and sealing integrity across manufacturers.

5. How does temperature affect diameter specifications?

Thermal expansion changes both body and liner dimensions:

-

Steel body: ΔD ≈ α × D × ΔT (α ≈ 12×10⁻⁶ /°C). A 600 mm valve at ΔT = 100 °C grows ~0.72 mm.

-

Rubber liner: Thermal contraction can slightly open the bore in hot service or constrict in cold service.

Design engineers must account for these shifts when installing in high-temperature steam or sub-zero pipelines.

6. Are butterfly valve diameters interchangeable between wafer, lug, and flanged types?

Yes—nominal diameter remains consistent across types, so a DN 150 wafer valve and a DN 150 lug valve share the same internal bore. Only the face-to-face dimensions and bolt patterns differ. This interchangeability simplifies spares management: you can stock one diameter in multiple styles for different installation needs.

References:

- ASME B16.5 – Pipe Flanges and Flanged Fittings – Official ASME standard detailing dimensions and tolerances for flanged connections used in valves and piping systems.

- EN 1092-1:2018 – Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories – European standard specifying flange dimensions and types relevant for butterfly valves.

- ISO 5752:1982 – Metal Valves for use in Flanged Piping Systems — Face-to-Face and End-to-End Dimensions – International standard defining face-to-face and end-to-end valve dimensions ensuring interchangeability.

- API Standard 609 – Butterfly Valves: Double-flanged, Lug- and Wafer-type – The American Petroleum Institute’s standard for design, dimensions, and testing of butterfly valves.

- AWWA C516-13 – Standard for Valves, Butterfly, Iron Body, Resilient Seated – American Water Works Association standard for butterfly valves used in potable water systems.