The primary ASTM standards governing ductile iron pipe include:

-

ASTM A746: Standard specification for ductile iron gravity sewer pipe, centrifugally cast with push-on joints.

-

ASTM A716: Specification for ductile iron culvert pipe used in drainage and culvert applications.

-

ASTM A674: Covers polyethylene encasement for ductile iron pipe to protect against corrosion.

-

ASTM A377: An index of all specifications for ductile iron pressure pipe.

-

ASTM A536: Defines the material properties (chemical and mechanical) for ductile iron castings used to manufacture pipe.

Together, these standards ensure consistent dimensions, mechanical integrity, corrosion protection, and performance of ductile iron piping systems.

Key ASTM Standards for Ductile Iron Pipe

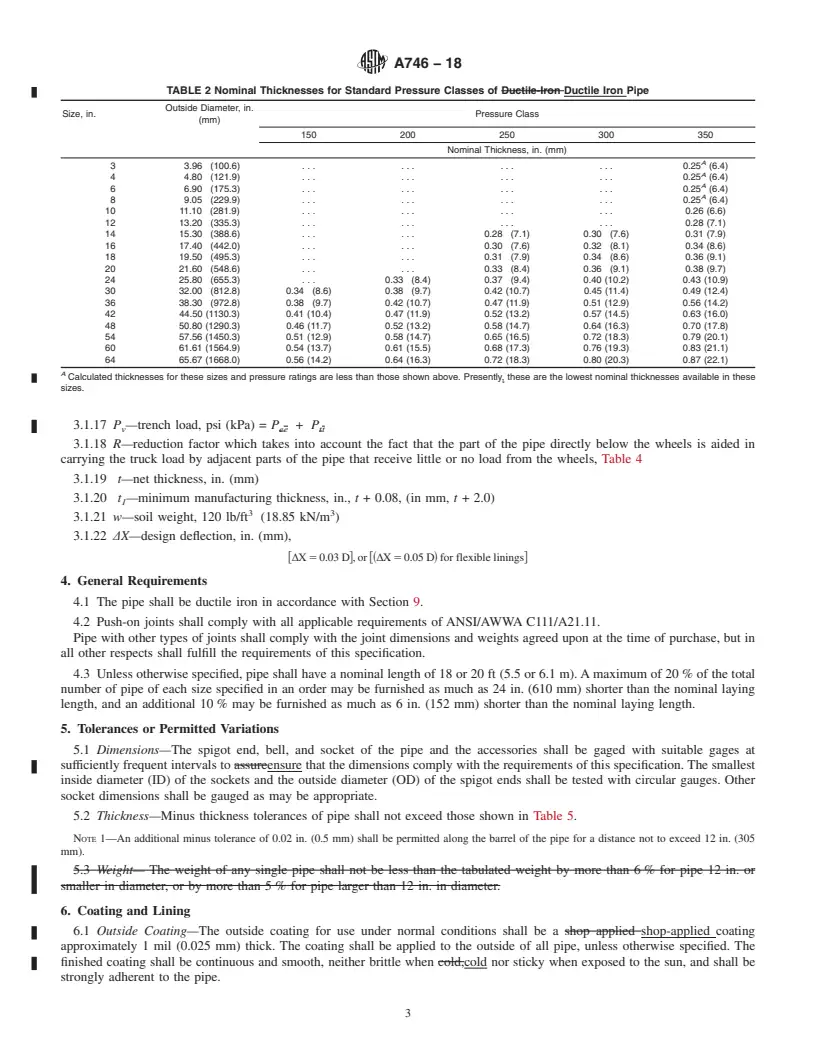

ASTM A746 – Ductile Iron Gravity Sewer Pipe

-

Scope: Covers 4–64 in. diameter ductile iron gravity sewer pipe, centrifugally cast, with push-on joints. Includes trench-load design and maximum cover depths for cement-lined and flexible-lined pipes.

-

Joint Types: Push-on (unrestrained) or other joint types by purchase agreement.

-

Applications: Municipal gravity sewer systems.

ASTM A716 – Ductile Iron Culvert Pipe

-

Scope: Applies to ductile iron culvert pipe 14–64 in. diameter, centrifugally cast for gravity flow of stormwater and drainage.

-

Coating/Lining: Typically asphaltic or cement-mortar.

-

Applications: Highway culverts, drainage structures.

ASTM A674 – Polyethylene Encasement for Ductile Iron Pipe

-

Scope: Specifies requirements for polyethylene sheeting used to encase ductile iron pipe in corrosive soils, enhancing corrosion protection.

-

Film Thickness: Minimum 8 mil.

-

Applications: Water and wastewater service lines in aggressive environments.

ASTM A377 – Standard Index of Specifications for Ductile Iron Pressure Pipe

-

Scope: An index listing all ASTM standards relevant to ductile iron pressure pipe for water and other liquids under pressure.

-

Utility: Quick reference to find applicable specifications for pipe, fittings, linings, and encasements.

ASTM A536 – Standard Specification for Ductile Iron Castings

-

Scope: Defines material requirements—chemical composition and mechanical properties—for ductile iron grades (e.g., 60-40-18, 65-45-12, 80-55-06) used in pipe and fittings.

-

Key Metrics: Tensile strength (min 400 MPa), yield strength (min 250 MPa), elongation (min 12 % for common grades).

Standards Comparison Table

| ASTM Standard | Title | Diameter Range | Joint / Treatment |

|---|---|---|---|

| A746 | Ductile Iron Gravity Sewer Pipe | 4–64 in. | Push-on joints; cement/flexible lining |

| A716 | Ductile Iron Culvert Pipe | 14–64 in. | Asphalt or cement-mortar lining |

| A674 | Polyethylene Encasement for Ductile Iron Pipe | Any diameter | 8 mil PE film |

| A377 | Index of Specifications for Ductile Iron Pipe | N/A | Reference standard list |

| A536 | Standard Spec. for Ductile Iron Castings | N/A | Defines material grades |

Frequently Asked Questions

Q1: What’s the difference between ASTM A746 and AWWA C151?

ASTM A746 covers gravity sewer pipe with push-on joints, whereas AWWA C151 covers ductile iron water pipe under pressure, including thickness design and lining requirements.

Q2: Why is ASTM A536 important for ductile iron pipe manufacturers?

ASTM A536 ensures the base ductile iron has consistent mechanical properties and graphite morphology, which directly impact pipe strength and toughness.

Q3: Can I use polyethylene encasement per ASTM A674 on any pipe diameter?

Yes—ASTM A674 specifies encasement requirements independent of diameter, focusing on film weight and durability.

Q4: How do I find all ASTM specs related to ductile iron pipe?

Refer to ASTM A377, the comprehensive index for ductile iron pressure pipe specifications.

Q5: Which standard governs ductile iron pipe for culverts vs. water mains?

-

Culverts: ASTM A716

-

Water mains (pressure): AWWA C151 (not an ASTM standard)

-

Sewer gravity: ASTM A746

References:

- ASTM A746 – Standard Specification for Ductile Iron Gravity Sewer Pipe

- ASTM A716 – Specification for Ductile Iron Culvert Pipe

- ASTM A674 – Standard Specification for Polyethylene Encasement for Ductile Iron Pipe

- ASTM A377 – Index of Specifications for Ductile Iron Pressure Pipe

- ASTM A536 – Standard Specification for Ductile Iron Castings