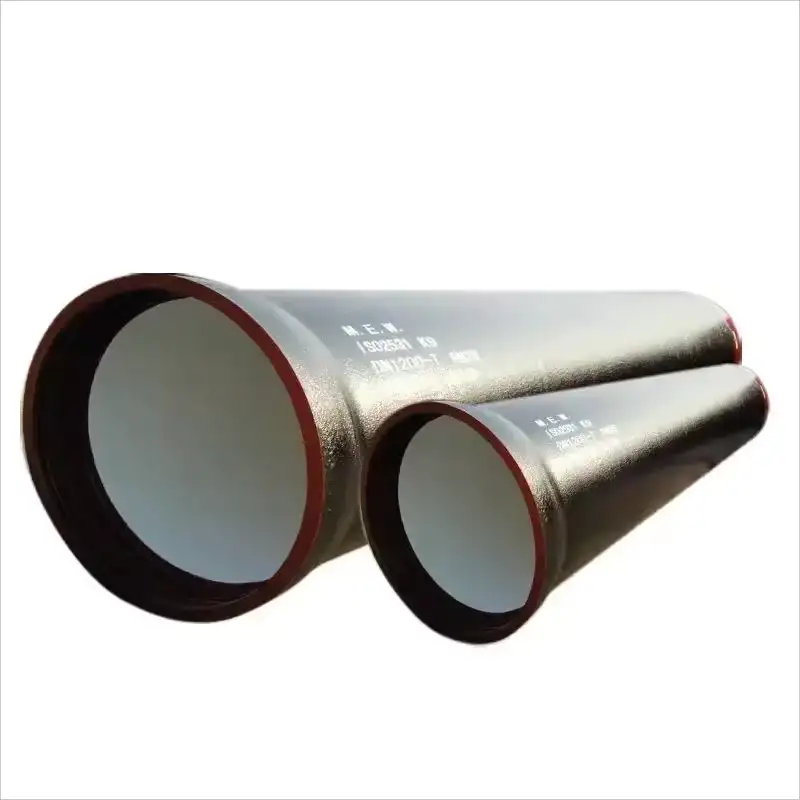

Ductile iron pipes are widely used in water distribution systems due to their strength, durability, and cost-effectiveness. However, to ensure their longevity and resistance to corrosion, these pipes are often coated or lined with various materials. Understanding the different types of coatings and linings can help in selecting the appropriate protection for specific environmental conditions.

Common Coatings and Linings for Ductile Iron Pipes

1. Cement-Mortar Lining (CML)

This is the standard internal lining for ductile iron pipes, providing a smooth surface that resists corrosion and minimizes water quality issues.

2. Polyethylene Encasement (PE)

A widely used external coating, polyethylene encasement involves wrapping the pipe in a loose-fitting polyethylene sleeve. This method is cost-effective and effective in protecting against corrosion, especially in aggressive soil conditions.

3. Zinc Coating

Zinc coatings, applied through metallizing or hot-dip methods, provide sacrificial protection to the pipe surface. This is particularly beneficial in areas with highly corrosive soils or environments.

4. Asphaltic Coating

A bituminous (asphalt-based) coating applied to the exterior of the pipe offers temporary protection during storage and handling. While not intended for long-term corrosion resistance, it serves as an initial protective layer.

5. Epoxy and Ceramic Linings

Epoxy coatings and ceramic-enhanced linings provide enhanced protection against internal corrosion and abrasion. These are particularly useful in pipes transporting potable water or wastewater.

Factors Influencing Coating Selection

-

Soil Conditions: Highly acidic or saline soils may require more robust coatings like zinc or epoxy.

-

Water Quality: Transporting potable water necessitates coatings that prevent contamination, such as cement-mortar linings or NSF-approved epoxy coatings.

-

Installation Environment: Areas prone to mechanical damage or abrasion may benefit from additional protective coatings.

-

Regulatory Standards: Compliance with local and international standards, such as AWWA (American Water Works Association) or ISO, ensures the selected coatings meet safety and performance requirements.

Best Practices for Installation and Maintenance

-

Proper Installation: Ensure coatings are applied and installed according to manufacturer specifications to maintain their protective qualities.

-

Regular Inspections: Conduct periodic inspections to detect any damage or degradation of coatings, allowing for timely maintenance.

-

Environmental Considerations: Choose coatings that align with the environmental conditions and regulatory requirements of the installation site.

Selecting the appropriate coating or lining for ductile iron pipes is crucial for ensuring their durability and performance. By considering factors such as soil conditions, water quality, and environmental factors, and adhering to industry standards, one can make informed decisions that enhance the lifespan and reliability of the piping system.