An irrigation check valve is a vital component in many irrigation systems. It ensures water flows in one direction and prevents reverse flow, which can cause issues like contamination, water waste, and system inefficiency. This article will cover the importance of irrigation check valves, their types, applications, and key benefits, along with a comparison of different models and answers to common questions.

1. What is an Irrigation Check Valve?

An irrigation check valve is a device used in irrigation systems to regulate the flow of water. It prevents the backflow or reverse flow of water into the system, ensuring that once the water moves in a certain direction, it doesn’t flow backward. This function is crucial for maintaining water pressure, protecting plants from contaminated water, and improving system efficiency.

Check valves are typically installed at various points in the irrigation system, such as the mainline, sprinkler heads, and pump outlets.

2. How Does an Irrigation Check Valve Work?

An irrigation check valve operates using a simple yet effective mechanism that prevents water from flowing backward. It is designed with a spring-loaded or gravity-operated mechanism that automatically closes when there is no water pressure or when water attempts to flow backward. This closure blocks the reverse flow, effectively sealing the system.

When water is flowing in the desired direction, the valve remains open, allowing water to pass freely. However, once the pressure drops or the flow is reversed, the valve closes tightly to stop the water from returning.

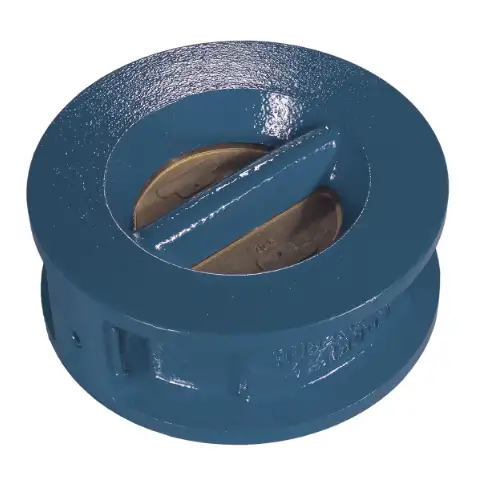

3. Types of Irrigation Check Valves

There are several types of irrigation check valves, each suited for different applications and systems. These include:

-

Spring-Loaded Check Valves: These use a spring mechanism to keep the valve closed when water pressure is low or reversed.

-

Gravity Check Valves: These valves rely on gravity to close the valve when the water flow is disrupted.

-

In-line Check Valves: Installed directly within the pipeline, in-line valves are ideal for maintaining consistent flow in irrigation systems.

-

Anti-Siphon Valves: Often used in sprinkler systems, these valves are designed to prevent water from being siphoned back into the water supply.

Each type has its own unique set of advantages depending on the system’s requirements.

4. Importance of Irrigation Check Valves

Irrigation check valves are critical in ensuring the efficiency and longevity of an irrigation system. They serve several key purposes:

-

Preventing Contamination: Without check valves, water can flow backward into the supply lines, potentially contaminating the water source.

-

Maintaining System Pressure: Check valves ensure that water doesn’t flow back into the system, which helps maintain proper pressure for efficient irrigation.

-

Reducing Water Waste: By stopping water from flowing backward, check valves prevent unnecessary drainage and water loss, which can be both costly and inefficient.

5. Key Benefits of Using Check Valves in Irrigation Systems

The benefits of installing irrigation check valves extend beyond just preventing backflow. Some of the major advantages include:

-

Increased Efficiency: Check valves help keep water moving in the correct direction, which maintains the efficiency of the irrigation system.

-

Better Water Conservation: By stopping water from draining back into the system, check valves reduce water wastage, which is crucial for sustainable irrigation practices.

-

Improved System Longevity: By preventing water from flowing backward, check valves help reduce wear and tear on pumps, pipes, and other irrigation components, ultimately extending the lifespan of the system.

-

Enhanced Water Quality: With proper backflow prevention, check valves help ensure the water flowing through the system is clean and safe, which is important for agricultural irrigation.

6. Common Problems and Solutions

While check valves are generally reliable, there are some issues that can arise:

-

Clogging: Sediment and debris can accumulate in the valve, causing it to malfunction. Regular cleaning and maintenance can prevent this.

-

Spring Failure: Over time, the spring in a spring-loaded valve may wear out. This issue can often be resolved by replacing the valve or its spring mechanism.

-

Installation Errors: Improper installation can result in a valve not performing correctly. It’s essential to ensure the valve is installed in the correct orientation and that the system’s pressure is properly regulated.

7. When to Install an Irrigation Check Valve

Check valves are most often installed in the following situations:

-

At the pump outlet: To prevent water from flowing backward into the pump.

-

On irrigation lines: To prevent water from flowing backward into the mainline after the system shuts off.

-

At sprinkler heads: To avoid drainage after the sprinkler is turned off.

8. Maintenance of Irrigation Check Valves

To ensure the longevity and proper functioning of irrigation check valves, regular maintenance is essential. Maintenance tasks include:

-

Cleaning the Valve: Remove any debris or sediment that may have accumulated within the valve. Use clean water and avoid harsh chemicals.

-

Inspecting for Leaks: Check for any signs of water leakage, especially around the valve’s seals.

-

Replacing Worn Parts: Over time, parts like springs or seals may degrade. Regularly inspect and replace worn-out components to keep the valve functioning optimally.

9. Comparison Table: Different Types of Irrigation Check Valves

| Type | Mechanism | Pros | Cons | Ideal Use Case |

|---|---|---|---|---|

| Spring-Loaded Check Valve | Uses a spring to prevent reverse flow | Reliable, easy to install | May wear out over time | Low-pressure systems |

| Gravity Check Valve | Relies on gravity to close the valve | Simple and cost-effective | May not be as precise in controlling flow | Sloped systems |

| In-line Check Valve | Installed within the pipeline | Compact, effective | Requires professional installation | Mainline installation |

| Anti-Siphon Valve | Prevents siphoning back into the supply | Prevents contamination | May be more expensive | Sprinkler systems |

10. FAQs

Q1: What happens if an irrigation check valve is installed incorrectly?

An incorrectly installed check valve can result in water flowing in the wrong direction, reducing system efficiency and potentially causing contamination of the water supply. It’s essential to follow installation guidelines and ensure the valve is oriented correctly to prevent these issues.

Q2: How do I know if my irrigation check valve is working properly?

To test the valve, observe whether water continues to flow through the system even when the pressure drops. If water flows backward, it indicates a malfunction. Additionally, check for signs of water leaks or a decrease in system pressure, which may suggest an issue with the valve.

Q3: Can check valves be used in all irrigation systems?

Yes, check valves can be used in most irrigation systems, but the type of valve required will depend on the specific needs of the system. For instance, anti-siphon valves are ideal for sprinkler systems, while in-line check valves are commonly used in mainline installations.

Q4: How often should irrigation check valves be replaced?

The lifespan of a check valve depends on the type and usage. On average, check valves should be replaced every 5 to 10 years, or sooner if you notice any signs of malfunction or reduced system performance.

Q5: Are there eco-friendly check valve options?

Yes, many modern irrigation systems are designed with sustainability in mind, and eco-friendly check valves are available. These valves are typically made from materials that are more durable and resistant to corrosion, reducing the need for frequent replacements.

Q6: What are the signs that my check valve needs maintenance?

Common signs that your check valve needs maintenance include water flow issues, leaks, or unusual noises. If you notice any of these problems, it’s essential to inspect the valve, clean it, and replace any damaged components.