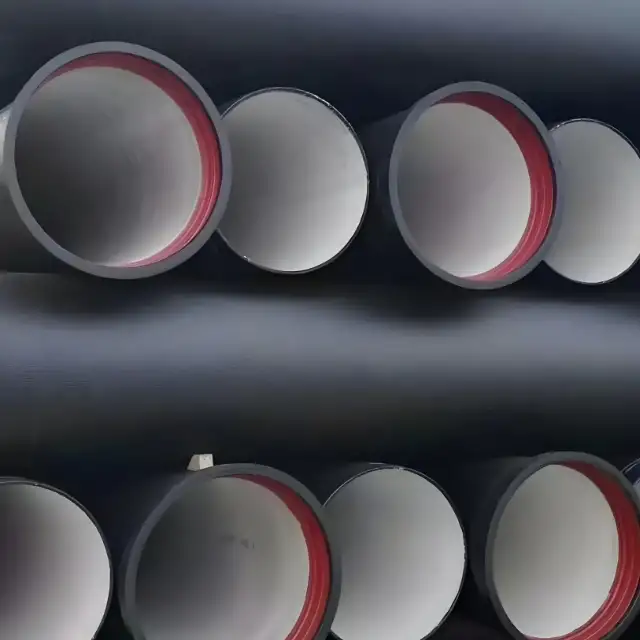

Ductile iron pipes are essential components in water distribution, wastewater treatment, and various infrastructure projects around the world. Their high strength, durability, and corrosion resistance make them a preferred choice for engineers and municipal planners.

Introduction

Ductile iron pipes have evolved significantly since their inception, offering improved mechanical properties over traditional cast iron counterparts. Their flexible nature—combined with enhanced ductility and fracture toughness—makes them suitable for diverse pressure applications. Today, ductile iron pipes are classified along several dimensions: pressure rating, manufacturing process, lining and coating systems, and regional standards. By understanding these classifications, professionals can select the right pipe for any given application while complying with international standards.

Key Classification Criteria

1. Pressure Rating and Design Strength

One of the primary ways ductile iron pipes are classified is by their pressure rating and design strength. This includes:

-

Nominal Pressure Class: Pipes are usually designated by a code (e.g., PN10, PN16, PN25) that indicates the maximum working pressure in bar. For instance, a PN16 ductile iron pipe is designed to withstand 16 bar of pressure.

-

SDR (Standard Dimension Ratio): This ratio relates the pipe’s diameter to its wall thickness, directly impacting its pressure resistance and structural integrity.

-

Application-Specific Design: Distribution pipes are designed for lower pressures and smaller diameters, while transmission or high-pressure pipes are built for major infrastructure projects.

Example Data Table – Pressure Ratings of Ductile Iron Pipes:

| Pressure Class | Nominal Pressure (bar) | Typical SDR | Common Uses |

|---|---|---|---|

| PN10 | 10 | 40–50 | Residential water supply |

| PN16 | 16 | 32–40 | Municipal distribution systems |

| PN25 | 25 | 25–32 | High-pressure transmission |

| PN40 | 40 | 20–25 | Industrial and specialized use |

Table Note: The figures provided are indicative and may vary based on regional standards and specific engineering requirements.

2. Manufacturing Process

Ductile iron pipes can also be classified based on their manufacturing method:

-

Centrifugally Cast Ductile Iron Pipes: Produced using centrifugal casting, these pipes offer uniform quality and excellent mechanical properties.

-

Rolled or Spun Ductile Iron Pipes: Utilized in certain regions, the rolling process can result in variations in wall thickness and yield a different set of mechanical characteristics.

-

Precise Tolerancing: Advances in casting techniques allow manufacturers to produce pipes that strictly adhere to dimensional tolerances, ensuring compatibility with diverse installation systems.

The choice of manufacturing process can affect the pipe’s performance, cost, and compliance with international standards.

3. Lining and Coating Systems

To enhance durability and prevent corrosion, ductile iron pipes are often classified by their lining or coating:

-

Cement Mortar Lined Pipes: These are widely used due to their cost-effectiveness and proven track record in resisting chemical attack.

-

Polymer Lined Pipes: Suitable for aggressive water conditions, polymer liners provide superior resistance to corrosion and scaling.

-

Bituminous Coating: Commonly applied for additional protection, bituminous coatings extend the pipe’s service life in challenging environments.

Advanced lining and coating technologies also ensure that the pipes meet both environmental regulations and longevity requirements, making them suitable for international markets.

4. Standard and Regulatory Compliance

Ductile iron pipes are manufactured according to various regional and international standards:

-

ISO Standards: Many manufacturers comply with ISO 2531, which covers requirements for ductile iron pipes and fittings.

-

EN Standards: In Europe, EN 545 and EN 598 specify the technical characteristics of ductile iron pipes used in water and sewage systems.

-

ASTM and ANSI Standards: In North America, standards such as ASTM A536 and corresponding ANSI codes help assure consistency in the mechanical properties and performance of ductile iron pipes.

-

Local Adaptations: Some regions modify or supplement these international standards to address specific environmental conditions and infrastructure demands.

Compliance with such regulations ensures that ductile iron pipes not only perform reliably but are also safe and environmentally sound in diverse global markets.

Case Studies: Real-World Applications

Municipal Water Distribution in Europe

A mid-sized European city upgraded its water distribution network by replacing older cast iron pipes with PN16-grade ductile iron pipes. The project, guided by EN 545 standards, resulted in:

-

Increased Durability: The replacement resulted in a 35% reduction in maintenance costs over five years.

-

Enhanced Flow Efficiency: Improved hydraulic performance reduced energy costs by approximately 20%.

-

Extended Service Life: The high-quality cement mortar lining provided consistent performance even in corrosive water conditions.

Industrial Application in North America

An industrial complex in North America required high-pressure transmission lines for cooling water supply. Engineers selected PN25-rated ductile iron pipes, produced under strict ASTM compliance. The installation not only met the rigorous demands of the facility but also demonstrated:

-

Reliability Under Stress: High-pressure and high-temperature conditions were managed without performance loss.

-

Operational Safety: Extensive testing confirmed the pipes’ ability to withstand fluctuating pressures, ensuring safety and continuity in operations.

These examples highlight how careful classification and compliance with standards lead to significant operational benefits and cost savings.

Data-Driven Analysis and Infographics

To further simplify the decision-making process, here are suggestions for infographics and data visualization that can be used on a website:

-

Pressure Class Distribution Pie Chart: Visualize the proportion of pipe use by nominal pressure class in different applications.

-

Performance Comparison Graph: Compare ductile iron pipe performance (e.g., lifespan, maintenance costs, hydraulic efficiency) under different lining and coating systems.

-

Global Standards Map: Show an interactive map that outlines which standards (ISO, EN, ASTM) apply in different regions, thereby aiding international users.

These visual elements enhance user engagement and aid in comprehensive understanding by translating complex technical data into digestible formats.

Ductile iron pipes play a pivotal role in modern infrastructure, and their classification based on pressure ratings, manufacturing processes, lining/coating systems, and regulatory compliance is essential for making informed purchasing and engineering decisions.

References:

- ISO 2531: Ductile Iron Pipes, Fittings, Accessories and Their Joints for Water Applications – International Organization for Standardization

- EN 545: Ductile Iron Pipes, Fittings, and Their Joints for Water Pipelines – European Committee for Standardization (CEN)

- ASTM A536 – Standard Specification for Ductile Iron Castings – ASTM International

- AWWA Standards for Ductile Iron Pipe Pressure Classes – American Water Works Association

- Ductile Iron Pipe – Wikipedia