Ductile iron pipes are widely used in water distribution systems due to their strength, durability, and resistance to corrosion. An essential parameter in designing and analyzing these systems is the absolute roughness of the pipe material. This property significantly influences the hydraulic performance of the pipeline, affecting factors like flow rate and pressure loss.

1. What Is Absolute Roughness?

Absolute roughness (denoted as ε) refers to the measure of the surface irregularities of a pipe’s interior. It is defined as the mean height of the roughness elements on the pipe wall. This parameter is crucial for determining the frictional resistance to fluid flow within the pipe.

In practical applications, absolute roughness is used in various empirical formulas, such as the Darcy-Weisbach equation and the Hazen-Williams equation, to calculate head loss and pressure drop due to friction.

2. Absolute Roughness of Ductile Iron Pipes

The absolute roughness of ductile iron pipes varies depending on factors like the pipe’s age, internal coating, and surface condition. For new, clean ductile iron pipes, the typical absolute roughness is approximately 0.26 mm (0.00085 ft). However, this value can increase over time due to factors such as corrosion, scaling, or internal deposits.

For instance, older or corroded ductile iron pipes may exhibit higher roughness values, potentially exceeding 1.5 mm (0.005 ft) . Therefore, it’s essential to consider the pipe’s condition when assessing its hydraulic performance.

3. Factors Influencing Pipe Roughness

Several factors can influence the absolute roughness of ductile iron pipes:

-

Age of the Pipe: Older pipes tend to accumulate deposits and corrosion, increasing surface roughness.

-

Internal Coatings: Coatings like cement lining can smooth the internal surface, reducing roughness.

-

Fluid Characteristics: The type of fluid, its velocity, and its temperature can affect the accumulation of deposits and corrosion rates.

-

Environmental Conditions: Factors such as soil composition and moisture levels can influence the rate of corrosion and scaling.

4. Impact of Roughness on Fluid Flow

The internal roughness of a pipe directly affects the frictional resistance to fluid flow. Higher roughness values lead to increased friction, resulting in higher energy consumption to maintain desired flow rates. This can also lead to higher pressure losses and reduced system efficiency.

In systems where maintaining specific flow rates is crucial, such as in water distribution networks, understanding and accounting for pipe roughness is vital for accurate system design and operation.

5. Calculating Pressure Loss Due to Roughness

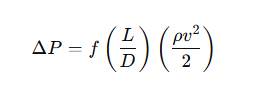

To calculate the pressure loss due to friction in a ductile iron pipe, engineers often use the Darcy-Weisbach equation:

Where:

-

ΔP = Pressure loss (Pa)

-

f = Darcy friction factor (dimensionless)

-

L = Length of the pipe (m)

-

D = Diameter of the pipe (m)

-

ρ = Density of the fluid (kg/m³)

-

v = Flow velocity (m/s)

The Darcy friction factor fff can be determined using the Colebrook-White equation, which incorporates the relative roughness of the pipe. For ductile iron pipes, the relative roughness is calculated as the absolute roughness divided by the pipe diameter.

6. Comparison with Other Pipe Materials

Understanding how ductile iron pipes compare to other materials in terms of roughness is essential for selecting the appropriate pipe material for a given application.

| Pipe Material | Absolute Roughness (mm) |

|---|---|

| Ductile Iron (new) | 0.26 |

| Cast Iron (new) | 0.26 |

| Steel (new) | 0.05 |

| Concrete (new) | 0.30 |

| PVC (new) | 0.0015 |

| Copper (new) | 0.0015 |

As shown in the table, ductile iron pipes have a higher absolute roughness compared to materials like PVC and copper. This higher roughness can lead to increased frictional losses and pressure drops in ductile iron pipelines.

7. Maintenance and Aging Effects

Over time, ductile iron pipes can experience changes in their internal surface due to factors like corrosion, scaling, and the accumulation of deposits. These changes can lead to an increase in the absolute roughness, resulting in higher frictional losses and reduced flow efficiency.

Regular maintenance, such as cleaning and internal inspections, can help mitigate these effects and maintain the hydraulic performance of the pipeline.

8. Frequently Asked Questions (FAQs)

Q1: What is the typical absolute roughness of a new ductile iron pipe?

A new, clean ductile iron pipe typically has an absolute roughness of approximately 0.26 mm (0.00085 ft). This value can vary based on factors like internal coatings and manufacturing processes.

Q2: How does the roughness of ductile iron pipes compare to other materials?

Ductile iron pipes have a higher absolute roughness compared to materials like PVC and copper. This higher roughness can lead to increased frictional losses and pressure drops in ductile iron pipelines.

Q3: How does pipe roughness affect fluid flow?

Higher pipe roughness increases the frictional resistance to fluid flow, leading to higher energy consumption, increased pressure losses, and reduced system efficiency.

Q4: How can I calculate pressure loss due to pipe roughness?

Pressure loss due to pipe roughness can be calculated using the Darcy-Weisbach equation, which incorporates the Darcy friction factor. The friction factor depends on the pipe’s relative roughness and the flow conditions.

Q5: Can the roughness of ductile iron pipes change over time?

Yes, over time, ductile iron pipes can experience changes in their internal surface due to factors like corrosion, scaling, and the accumulation of deposits, leading to an increase in the absolute roughness.

Q6: How can I mitigate the effects of increased pipe roughness?

Regular maintenance, such as cleaning and internal inspections, can help mitigate the effects of increased pipe roughness and maintain the hydraulic performance of the pipeline.