TR Flex Pipe is a type of flexible, jointed pipe system commonly used in water and wastewater infrastructure projects. It is designed to provide enhanced flexibility and strength, making it suitable for challenging conditions where conventional rigid piping may be less effective. TR Flex Pipe systems are known for their ability to resist corrosion, accommodate soil movements, and simplify the installation process.

This article aims to provide a comprehensive overview of TR Flex Pipe, covering its composition, benefits, key applications, installation process, and comparisons with other common piping systems. By understanding the features and advantages of TR Flex Pipe, professionals in construction, water management, and infrastructure projects can make informed decisions when selecting piping systems for their needs.

1. What is TR Flex Pipe?

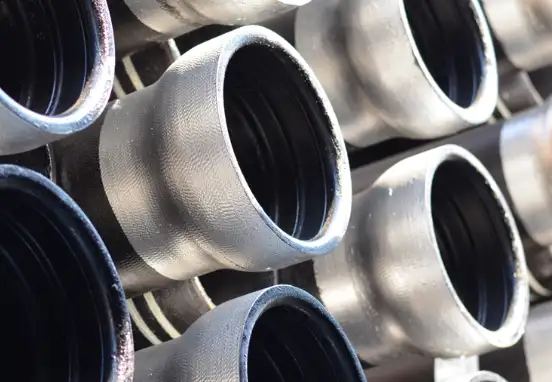

TR Flex Pipe is a specific type of pipe system made from ductile iron, known for its flexibility, durability, and resistance to corrosion. Unlike traditional rigid piping, TR Flex Pipe utilizes an advanced joint design that allows for controlled movement, making it ideal for areas with shifting soils, seismic activity, or other environmental factors that may cause ground movements.

The TR Flex system is often used for water transmission and distribution in municipal, industrial, and commercial projects. The system’s unique joint design, which includes a mechanical coupling, provides flexibility without compromising the pipe’s strength or integrity.

Composition and Design

-

Ductile Iron: The pipe itself is made from ductile iron, a material known for its high tensile strength, impact resistance, and ability to withstand high pressures. Ductile iron is a strong, long-lasting material that is less likely to crack under stress compared to traditional cast iron.

-

TR Flex Joint: The defining feature of TR Flex Pipe is its flexible joint system. This joint design allows for axial movement, rotation, and deflection, making it suitable for use in environments with shifting soils, high seismic risk, or areas that require significant pipe expansion or contraction.

-

Corrosion Resistance: The pipes are often coated with a protective layer such as cement lining, epoxy, or bituminous coating to enhance corrosion resistance, particularly when exposed to water or aggressive chemicals.

2. Benefits of TR Flex Pipe

TR Flex Pipe offers several advantages over traditional rigid piping systems. Below are the key benefits:

2.1 Flexibility and Seismic Resistance

The unique flexible joint design allows TR Flex Pipe to absorb ground movements, such as settling or shifting due to seismic activity, making it ideal for use in areas prone to earthquakes or soil instability. The flexibility ensures that the pipe can accommodate shifts in the ground without compromising its integrity or risking breakage.

2.2 Durability and Longevity

Made from ductile iron, TR Flex Pipe offers superior strength and durability compared to other materials like PVC or standard cast iron. The pipes are resistant to cracking, impact damage, and fatigue, which extends their service life, especially in high-pressure systems.

2.3 Corrosion Resistance

TR Flex Pipes are often lined with coatings such as cement or epoxy to provide an additional layer of protection against corrosion. This makes the pipes ideal for use in corrosive environments, such as wastewater treatment plants or areas with high chemical exposure.

2.4 Easy Installation and Maintenance

TR Flex Pipe’s flexible joint system simplifies installation, as the pipes can be installed quickly without the need for complex fittings or special tools. Additionally, the system requires less maintenance due to its ability to absorb soil movement and prevent pipe breakage.

2.5 Cost-Effective

Although TR Flex Pipe can be more expensive initially than other piping systems, its durability, flexibility, and minimal maintenance requirements can reduce long-term costs, making it a cost-effective solution for many applications.

3. Applications of TR Flex Pipe

TR Flex Pipe is commonly used in a variety of applications, particularly in municipal water systems and industrial projects. Its flexibility and durability make it ideal for environments that experience soil movement or seismic activity. Below are some of the most common applications:

3.1 Water Transmission and Distribution

TR Flex Pipe is widely used in municipal water systems for transporting potable water over long distances. The flexibility of the joint design ensures that the pipe can withstand pressure changes and ground movement without risking rupture or failure.

3.2 Wastewater Systems

TR Flex Pipe is ideal for sewage and wastewater systems, where the pipes are often exposed to aggressive conditions such as chemicals, high pressure, and fluctuating temperatures. The corrosion-resistant coatings on TR Flex Pipes make them a reliable choice for underground sewage lines.

3.3 Industrial Pipelines

Industries such as chemical processing, power generation, and manufacturing often use TR Flex Pipe to transport liquids and gases under high pressure. The flexibility and durability of the pipe make it suitable for use in harsh environments with fluctuating pressures and temperatures.

3.4 Seismic Zones

TR Flex Pipe is commonly used in earthquake-prone regions due to its ability to absorb ground movements. The flexibility in the joints allows the pipe to maintain its structural integrity even during seismic events, preventing fractures or ruptures that can occur with rigid piping systems.

4. Comparison of TR Flex Pipe with Other Piping Systems

To provide a better understanding of when TR Flex Pipe is the ideal choice, it is helpful to compare it with other common piping materials. Below is a comparison between TR Flex Pipe, standard ductile iron pipe, PVC, and steel pipes.

| Property | TR Flex Pipe | Ductile Iron (Standard) | PVC Pipe | Steel Pipe |

|---|---|---|---|---|

| Flexibility | High (flexible joints) | Low (rigid joints) | Moderate (depends on pressure) | Low (rigid joints) |

| Corrosion Resistance | High (protective coatings) | Moderate (depends on coating) | Low (prone to chemical degradation) | Moderate (requires protective coating) |

| Durability | Very high (long lifespan) | High (long lifespan) | Moderate (less durable under pressure) | High (long lifespan) |

| Installation Ease | Easy (flexible joints reduce complexity) | Moderate (requires rigid joints) | Easy (lightweight, easy to handle) | Moderate (requires welding or threading) |

| Pressure Capacity | High | Very high (suitable for high-pressure) | Moderate (limited to lower pressures) | Very high (suitable for heavy-duty applications) |

| Cost | Higher initial cost | Moderate to high | Low (cheapest option) | High (expensive, especially for large diameter pipes) |

5. Key Considerations When Choosing TR Flex Pipe

When deciding whether TR Flex Pipe is the right choice for a specific project, it’s important to consider the following factors:

5.1 Soil and Environmental Conditions

TR Flex Pipe is ideal for use in environments with shifting soils, seismic activity, or areas that experience significant ground movement. If the project site is prone to such conditions, TR Flex Pipe is the best option to prevent pipe failure.

5.2 Pressure and Flow Requirements

TR Flex Pipe is designed to handle high-pressure systems, making it suitable for water transmission, industrial pipelines, and other applications requiring durable, high-pressure piping solutions.

5.3 Budget Constraints

While TR Flex Pipe can have a higher initial cost than other types of piping, its long lifespan and minimal maintenance requirements can offset the initial investment over time. For projects where durability and flexibility are critical, TR Flex Pipe offers long-term value.

6. Commonly Asked Questions (FAQs)

1. How does the TR Flex joint system work?

The TR Flex joint system allows for movement between pipe sections, accommodating soil shifts, pressure changes, and seismic activity. The flexible joint design helps reduce the stress on the pipe, preventing fractures and extending the life of the system.

2. Can TR Flex Pipe be used in areas with high seismic activity?

Yes, TR Flex Pipe is an excellent choice for earthquake-prone areas. The flexible joints are specifically designed to absorb ground movements, ensuring that the pipe remains intact during seismic events without rupturing or cracking.

3. How is TR Flex Pipe installed?

TR Flex Pipe installation is relatively straightforward, as the flexible joints reduce the need for complex fittings and reduce the risk of pipe breakage during installation. The pipes are simply aligned and secured using mechanical couplings, making the process faster and more efficient than with rigid piping systems.

4. What are the corrosion protection options for TR Flex Pipe?

TR Flex Pipes can be coated with a variety of corrosion-resistant materials, including cement lining, epoxy coatings, or bituminous coatings. These coatings protect the pipe from aggressive chemicals and environmental factors that could otherwise lead to corrosion.

5. What is the expected lifespan of TR Flex Pipe?

TR Flex Pipe is known for its durability and long service life. With proper installation and maintenance, these pipes can last for 50 to 100 years, depending on the environmental conditions and the nature of the fluids being transported.

6. How does TR Flex Pipe compare to other materials like PVC or steel?

TR Flex Pipe offers superior flexibility and resistance to seismic activity compared to rigid materials like PVC and steel. It also provides better corrosion resistance than PVC and is more durable than steel, especially in harsh environments with high pressures and fluctuating temperatures.

Conclusion

TR Flex Pipe is a highly flexible and durable piping solution suitable for a wide range of applications. Whether used in municipal water systems, industrial pipelines, or areas prone to seismic activity, TR Flex Pipe offers unmatched flexibility, corrosion resistance, and longevity. By understanding its benefits, key applications, and how it compares to other piping materials, professionals can make informed decisions for their infrastructure projects.