Ductile iron and austempered ductile iron (ADI) are both cast irons known for their strength and versatility. While they share similarities, their differences in microstructure, mechanical properties, and heat treatment processes make them suitable for distinct applications. This article delves into these differences to provide a comprehensive understanding of each material.

Microstructure Comparison

| Property | Ductile Iron | Austempered Ductile Iron (ADI) |

|---|---|---|

| Graphite Form | Nodular (spheroidal) | Nodular (spheroidal) |

| Matrix Structure | Ferrite, pearlite, or martensite | Ausferrite (acicular ferrite + stabilized austenite) |

| Strength | Moderate | High |

| Ductility | High | Moderate to high |

| Hardness | Moderate to high | High |

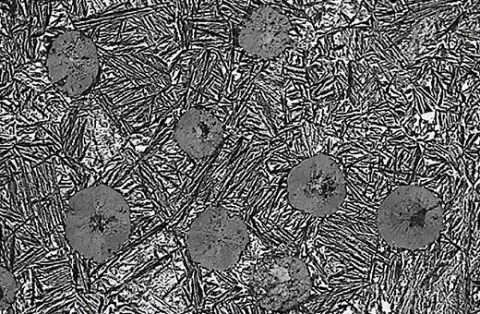

Ductile iron’s matrix can vary based on its composition and heat treatment, leading to a range of mechanical properties. In contrast, ADI undergoes a specific heat treatment process that transforms its microstructure into ausferrite, enhancing its strength and wear resistance.

Mechanical Properties

| Property | Ductile Iron (Grade 65-45-12) | Austempered Ductile Iron (Grade 700-2) |

|---|---|---|

| Tensile Strength | 448 MPa | 700 MPa |

| Yield Strength | 310 MPa | 500 MPa |

| Elongation at Break | 12% | 2% |

| Hardness | 220 HB | 350 HB |

| Impact Toughness | Moderate | High |

The data above illustrates that ADI offers superior strength and hardness compared to standard ductile iron grades. However, this comes with a trade-off in ductility, which may be a consideration depending on the specific application.

Heat Treatment Processes

| Process | Ductile Iron | Austempered Ductile Iron (ADI) |

|---|---|---|

| Heat Treatment | Annealing, normalizing, quenching | Austempering (isothermal heat treatment) |

| Temperature Range | 800–900°C | 260–400°C |

| Cooling Medium | Air, oil, or water | Molten salt bath |

| Microstructure Result | Ferrite, pearlite, or martensite | Ausferrite |

The austempering process involves heating ductile iron to an austenitizing temperature, followed by quenching in a molten salt bath to achieve the desired microstructure. This process enhances the material’s mechanical properties, making ADI suitable for more demanding applications.

Applications

| Application Area | Ductile Iron | Austempered Ductile Iron (ADI) |

|---|---|---|

| Automotive Components | Crankshafts, gears, suspension parts | High-performance gears, brake rotors |

| Industrial Machinery | Pump housings, machine frames | Wear-resistant components, gears |

| Infrastructure | Pipes, manhole covers | Railroad wheels, structural components |

Ductile iron’s versatility makes it suitable for a wide range of applications, while ADI’s enhanced properties make it ideal for components subjected to high stress and wear.

Advantages and Limitations

Ductile Iron

Advantages:

-

High ductility and impact resistance.

-

Good machinability and castability.

-

Cost-effective for large-scale production.

Limitations:

-

Lower strength and hardness compared to ADI.

-

Limited wear resistance.

Austempered Ductile Iron (ADI)

Advantages:

-

Superior strength and wear resistance.

-

Enhanced fatigue and impact resistance.

-

Suitable for high-performance applications.

Limitations:

-

Reduced ductility.

-

More complex and costly heat treatment process.

Frequently Asked Questions (FAQs)

1. What is the primary difference between ductile iron and austempered ductile iron?

The main difference lies in their microstructure and mechanical properties. While both materials have nodular graphite inclusions, ductile iron’s matrix can vary, leading to a range of properties. In contrast, ADI undergoes a specific heat treatment process that transforms its microstructure into ausferrite, enhancing its strength and wear resistance.

2. How does the austempering process affect the properties of ductile iron?

Austempering involves heating ductile iron to an austenitizing temperature and then quenching it in a molten salt bath. This process results in the formation of ausferrite, a microstructure that combines acicular ferrite and stabilized austenite, leading to improved strength, hardness, and wear resistance.

3. Can austempered ductile iron replace steel in all applications?

While ADI offers strength and wear resistance comparable to steel, its reduced ductility may limit its use in applications where flexibility and elongation are critical. Therefore, the suitability of ADI as a replacement for steel depends on the specific requirements of the application.

4. What are the cost implications of using ADI over ductile iron?

The enhanced properties of ADI come at a higher cost due to the additional heat treatment process. However, the superior performance of ADI can lead to cost savings in applications where reduced maintenance and longer service life are beneficial.

5. What industries benefit most from using ADI?

Industries such as automotive, industrial machinery, and infrastructure benefit from ADI’s combination of strength, wear resistance, and cost-effectiveness, making it ideal for components like gears, crankshafts, and structural parts.

6. Are there environmental benefits to using ADI?

Yes, ADI’s lighter weight can contribute to energy savings in transportation and machinery, and its production process can be more energy-efficient compared to traditional steel manufacturing.

Conclusion

Both ductile iron and austempered ductile iron offer unique advantages, making them suitable for different applications. Understanding their differences in microstructure, mechanical properties, and heat treatment processes is crucial in selecting the appropriate material for specific engineering needs.