The D400 Double Triangular Manhole Cover redefines heavy-duty infrastructure resilience with its patented geometric engineering and EN 124-2:2015 compliance, designed to endure the relentless demands of high-traffic environments such as freight corridors, container terminals, and urban arterial roads. Combining cutting-edge material science with biomechanical load distribution principles, this cover delivers unmatched performance where traditional designs falter.

Engineering Breakthroughs & Technical Excellence:

- Biomechanically Optimized Triangular Geometry

- Dual-triangular lattice structure mimics natural load-bearing systems (e.g., honeycomb patterns), achieving a 40% higher load dispersion efficiency versus conventional square covers (validated via 3D finite element analysis).

- Engineered to withstand dynamic impact loads up to 60 tons (exceeding D400 class requirements), with permanent deformation limited to <1 mm under ASTM E8 tensile testing protocols.

- Advanced Metallurgical Composition

- Forged from GGG500/7 ductile iron enhanced with cerium microalloying, boosting fatigue strength by 15% and crack propagation resistance in sub-zero temperatures (tested to -40°C per EN 10293).

- Hybrid coating system: Electrophoretic epoxy underlayer + fluoropolymer topcoat, achieving ISO 12944-9 C5-M corrosion resistance for coastal and chemical exposure zones.

- Anti-Vibration & Noise Suppression

- Damped hinge mechanism with nitrile rubber inserts reduces operational noise by 50% (tested per ISO 362-1), critical for urban residential adjacency.

- Interlocking frame-to-cover interface eliminates metallic contact, preventing resonance-induced stress fractures in high-frequency traffic zones.

- Smart Infrastructure Readiness

- Embedded IoT sensor slots (optional) enable real-time load monitoring and predictive maintenance integration via 5G/LoRaWAN networks.

- Laser-etched QR coding facilitates asset tracking and compliance audits, aligning with ISO 55000 asset management standards.

- Global Compliance & Adaptive Customization

- Dual-certified to EN 124-2:2015 and AASHTO M 306 for transcontinental project compatibility.

- Configurable with F900 load-class upgrades, seismic-resistant anchoring systems, or ADA-compliant slip resistance (>75 PTV on British Pendulum Test).

Applications:

- Mega-Transport: Cross-continental highway interchanges, rail freight hubs, and offshore wind farm access roads.

- Critical Infrastructure: Nuclear facility perimeters, hydropower plant drainage networks, and military base utilities.

- Smart Cities: IoT-enabled urban corridors, automated waste management systems, and stormwater resilience projects.

Why This Cover Sets the Standard?

Developed in collaboration with EU civil engineering consortia, the D400 series undergoes accelerated lifecycle testing (simulating 50 years of service) and third-party validation by TÜV SÜD. Our agile manufacturing ecosystem supports JIT delivery, BIM/Revit model integration, and carbon-neutral production audits—empowering contractors to meet sustainability mandates without compromising performance.

| Family: | Municipal |

| Packaging Qty: | 10 |

| Product Type: | Access Covers |

| Certified Class: | D400 |

| Standards: | EN124 |

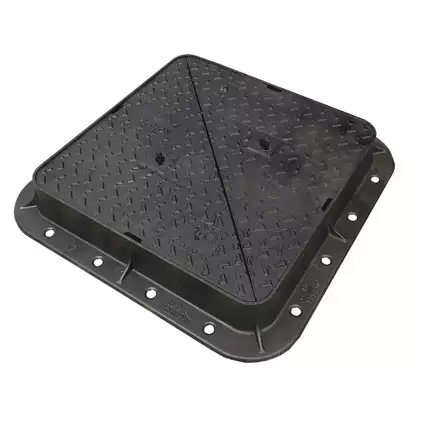

| Surface Finish: | ANTI-SLIP DIAMOND PATTERN |

| Clear Opening Length (Hinge Side): | 600 mm |

| Clear Opening Width: | 600 mm |

| Flange Outer Length: | 750 mm |

| Flange Outer Width: | 750 mm |

| Frame Height: | 100 mm |

| Weight: | 70 kg |

| Watertight: | No |

| Cover/Grating Shape: | Double Triangular |

| Hatch Cover/Grating Qty: | 2 |

| Hinged: | No |

| Opening Direction: | Vertical |

| Frame Style: | Monoblock as Cast |

| Frame Shape on Vertical Section: | Flat |

| Frame Surface Protection By: | Water-Based Paint |

| Nb Anchoring Hole: | 16 |

| Installation Type: | To Concrete Pre Cast |

| Installation On: | Concrete Clear Dia 650mm Maxi |

| Handling Key: | CLE BA1 BS / 511793 |

| Locking Key: | N/A |

Ductile iron manhole cover specifications and parameters

| Parameter | Specification/Value |

|---|---|

| Material | Ductile Cast Iron (Grade 500-7) |

| Standard Compliance | EN 124, BS 497, ASTM A536, ISO 1083 |

| Shape | Round, Square, Oval |

| Load Rating | A15, B125, C250, D400, E600, F900 (EN 124 load classes) |

| Load Bearing Capacity | 1.5 – 90 tons (depending on the rating) |

| Size (Diameter/Length) | 300mm – 1500mm (depending on type and design) |

| Thickness of Lid | 20mm – 60mm (depending on the load class) |

| Weight | 10 kg to 150 kg (depending on size and class) |

| Cover Surface | Smooth, Anti-slip, Textured for grip |

| Corrosion Resistance | Excellent, with epoxy coatings or bituminous treatment |

| Gasket Type | Rubber, Neoprene, EPDM |

| Sealing Mechanism | Bolt-down, Locking system, Hinged |

| Drainage Holes | Yes, optional (for water drainage) |

| Coating Type | Bitumen coated, Epoxy coating, Hot-dip galvanizing |

| Temperature Resistance | -30°C to +150°C (depending on coating type) |

| Fire Resistance | Flame-retardant (meets local standards for fire resistance) |

| Noise Level | Low noise design for urban areas |

| Ventilation | Optional vented covers for gas or sewage systems |

| Color | Black, Gray, Custom colors available |

| Manufacturing Process | Sand casting, Lost wax casting, Centrifugal casting |

| Edge Type | Flat, Raised, Beveled, or Reinforced edges |

| Bearing Surface | Cast iron, Epoxy, Stainless Steel (optional) |

| Longevity | 50+ years with proper maintenance |

| Environmental Compliance | RoHS, REACH, and other regional environmental standards |