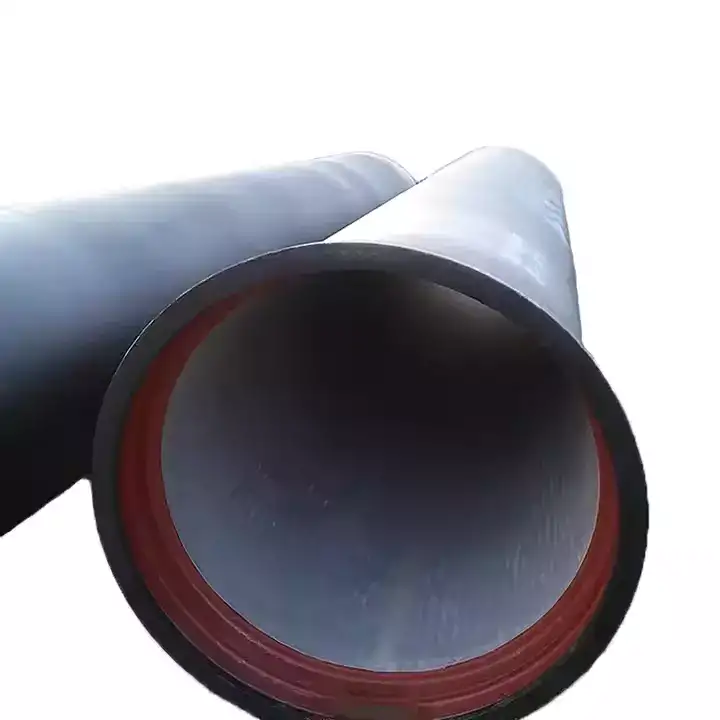

Class K12 DN2000 ductile iron pipe features a 2 000 mm internal diameter and a 30 mm wall (e = 12·(0.5 + 0.001 · 2000)) per ISO 2531, with cement-mortar lining (ISO 4179) and zinc/bitumen coating (ISO 8179) for superior corrosion resistance. It’s rated for pressures up to PN 25–40 and excels in open-cut, HDD and pipe-jacking installations using Tyton, restrained-mechanical or ANSI-flanged joints. Proven to exceed 100 years of service life under normal conditions, it delivers exceptional reliability for municipal, industrial and irrigation networks.

Application Scenarios

Class K12 DN2000 pipes serve as primary trunk mains in municipal water distribution, where large flow volumes demand minimal head loss and strict potable-water purity. In sewerage systems, their smooth mortar lining resists deposition and eases maintenance. They span long-distance irrigation canals, reservoir feeds and hydraulic works, maintaining structural integrity across varied terrains. For industrial loops—power plants, factories, large HVAC circuits—their toughness withstands vibration, surge and cyclic loading . Finally, compatibility with trenchless methods (HDD up to DN 1000; pipe jacking beyond) enables crossings under roads, rivers and ecological zones without open-cut disruption.

Service Life

Modern ductile iron pipe consistently achieves 100+ years of service, as evidenced by utilities in the DIPRA Century Club. Internally, cement-mortar linings (ISO 4179) virtually eliminate corrosion, while external zinc/bitumen coatings (ISO 8179) provide sacrificial protection against aggressive soils. Independent studies show ductile iron outlasts alternatives (e.g. HDPE’s ~55 years) with minimal maintenance, lowering life-cycle cost. An Environmental Product Declaration confirms recyclability at end-of-life and sustained mechanical performance throughout service.

Installation & Connection

-

Joint Types: Push-on (Tyton) gaskets per ISO 4633, mechanical restraint (AWWA C111) and ANSI B16.1 flanges enable rapid, leak-free assembly with standard tooling.

-

Open-Cut & Trenchless: Open-trench follows AWWA C600 guidelines; trenchless options (HDD/PJ) minimize surface impact and accelerate schedules.

-

Angular Deflection: Socket-spigot joints allow ~±0.5 % deflection (~10 mm over 2 m), reducing the need for bends and fittings.

-

Backfill & Recovery: Pipes can be backfilled immediately after assembly, even in wet conditions, boosting productivity in diverse climates.

International Standards

-

ISO 2531 / EN 545: Ductile iron pipes, fittings & accessories for potable water.

-

ISO 7186 / EN 598: Products for sewerage applications.

-

ISO 13470: Requirements for trenchless jacking pipe components.

-

ISO 4179: Cement-mortar lining specifications .

-

ISO 8179: Zinc coating and external protection standards .

Other Series Price Comparison

| Class | Wall Thickness @ DN2000 (mm) | Typical Price (USD/m) |

|---|---|---|

| K7 | 17.5 | 400–480 |

| K8 | 20.0 | 420–560 |

| K9 | 22.5 | 430–600 |

| K12 | 30.0 | 425–558 |

Advantages

-

Structural Strength: Resists up to 3× PFA and high external loads (traffic, settlement).

-

Leak-Free Integrity: Gasketed and restrained joints maintain performance under surge and cyclic pressures.

-

Corrosion Protection: Multi-layer exterior coatings and robust linings ensure durability in varied soils.

-

Sustainability: High recycled content; fully recyclable at end-of-life; low carbon footprint.

-

Flexible Alignment: Joint deflection reduces fittings, simplifies routing and lowers labor.

Frequently Asked Questions

Q1: What does Class K12 mean?

It defines wall-thickness via ISO 2531: e = 12·(0.5 + 0.001 · DN), giving ~30 mm at DN 2000.

Q2: Which standards apply?

Core standards are ISO 2531/EN 545 (water), ISO 7186/EN 598 (sewage), ISO 13470 (trenchless), ISO 4179 (lining) and ISO 8179 (coating).

Q3: How long is service life?

With proper lining/coating, 100+ years is routinely achieved, often reaching 125 years in favorable conditions.

Q4: What installation methods are supported?

Compatible with open-cut (AWWA C600), HDD and pipe-jacking, using push-on, mechanical and flanged joints.

Q5: How does K12 compare cost-wise?

At USD 425–558/m FOB China, K12 often proves most economical over its life cycle, despite higher upfront cost versus thinner classes.

Case Studies

-

Rapid Repair, Germany: A major contractor needed a DN 2000 external repair coupling in 24 hours; VIPSeal delivered a custom solution that restored full service under pressure.

-

Aurora, CO Water Dept.: Facing high cyclic loading from pumping operations, the city selected DN 2000 DI mains for their proven resilience; decades later performance remains unimpaired.

-

Birmingham Wildfire Test: In May 2022, a DN 2000 pipeline underwent a controlled wildfire temperature trial, demonstrating negligible loss of integrity under extreme heat.

ductile iron pipe dimensions

| Pipe body weight (kg/m) | |||||||||||||||

| (Inside Diameter) | (Outside Diameter) | Socket Weight | K8 | K9 | K10 | C class | Total weight of Active Length=6M (kg) | Total weight of Active Length=5.7M (kg) | |||||||

| DN(mm) | OD(mm) | ≈ kg | Class | kg/m | K8 | K9 | K10 | C class | K8 | K9 | K10 | C class | |||

| 80 | 98 | 3.40 | 12.20 | 12.20 | 12.20 | C40 | 9.10 | 77.00 | 77.00 | 77.00 | 58.00 | 73.00 | 73.00 | 73.00 | 55.00 |

| 100 | 118 | 4.30 | 14.90 | 15.10 | 15.10 | C40 | 11.12 | 93.70 | 95.00 | 95.00 | 71.00 | 90.00 | 91.00 | 90.00 | 68.00 |

| 125 | 144 | 5.70 | 18.90 | C40 | 119.00 | ||||||||||

| 150 | 170 | 7.10 | 21.80 | 22.80 | 22.80 | C40 | 16.48 | 138.00 | 144.00 | 144.00 | 106.00 | 132.00 | 138.00 | 137.00 | 101.00 |

| 200 | 222 | 10.30 | 28.70 | 30.60 | 30.60 | C40 | 22.62 | 183.00 | 194.00 | 194.00 | 146.00 | 174.00 | 185.00 | 185.00 | 139.00 |

| 250 | 274 | 14.20 | 35.60 | 40.20 | 44.30 | C40 | 32.63 | 228.00 | 255.00 | 280.00 | 210.00 | 218.00 | 244.00 | 267.00 | 200.00 |

| 300 | 326 | 18.90 | 45.30 | 50.80 | 56.30 | C30 | 43.90 | 290.00 | 323.00 | 357.00 | 282.00 | 278.00 | 309.00 | 340.00 | 269.00 |

| 350 | 378 | 23.70 | 55.90 | 63.20 | 69.60 | C30 | 51.88 | 359.00 | 403.00 | 441.00 | 335.00 | 343.00 | 384.00 | 420.00 | 319.00 |

| 400 | 429 | 29.50 | 67.30 | 75.50 | 83.70 | C30 | 60.78 | 433.00 | 482.00 | 532.00 | 394.00 | 414.00 | 460.00 | 506.00 | 376.00 |

| 450 | 480 | 38.30 | 80.00 | 89.30 | 99.00 | C30 | 73.30 | 515.00 | 575.00 | 632.00 | 472.00 | 492.00 | 550.00 | 597.00 | 450.00 |

| 500 | 532 | 42.80 | 92.80 | 104.30 | 115.60 | C30 | 87.20 | 600.00 | 669.00 | 736.00 | 566.00 | 572.00 | 638.00 | 702.00 | 540.00 |

| 600 | 635 | 59.30 | 122.00 | 137.30 | 152.00 | C30 | 120.62 | 791.00 | 882.00 | 971.00 | 783.00 | 755.00 | 842.00 | 926.00 | 747.00 |

| 700 | 738 | 79.10 | 155.00 | 173.90 | 193.00 | C25 | 142.15 | 1009.00 | 1123.00 | 1237.00 | 932.00 | 963.00 | 1071.00 | 1179.00 | 889.00 |

| 800 | 842 | 102.60 | 192.00 | 215.20 | 239.00 | C25 | 177.07 | 1255.00 | 1394.00 | 1537.00 | 1165.00 | 1197.00 | 1330.00 | 1465.00 | 1112.00 |

| 900 | 945 | 129.60 | 232.00 | 260.20 | 289.00 | C25 | 197.68 | 1521.00 | 1691.00 | 1863.00 | 1446.00 | 1452.00 | 1613.00 | 1777.00 | 1257.00 |

| 1000 | 1048 | 161.30 | 275.00 | 309.30 | 343.20 | C25 | 266.28 | 1811.00 | 2017.00 | 2221.00 | 1759.00 | 1729.00 | 1925.00 | 2118.00 | 1679.00 |

| 1100 | 1152 | 194.70 | 362.80 | 2372.00 | |||||||||||

| 1200 | 1255 | 237.70 | 374.00 | 420.10 | 466.10 | C25 | 373.88 | 2482.00 | 2758.00 | 3034.00 | 2481.00 | 2370.00 | 2632.00 | 2894.00 | 2369.00 |

| 1400 | 1462 | 279.30 | 547.20 | 3563.00 | |||||||||||

ductile iron pipe Mechanical property

| Mechanical Property | |||||||

| Nominal Diameter | Hydraulic test | Tensile strength | Elogation | Yield strength | Bending strength | Brinell hardness | Thickness of cement lining |

| DN(MM) | Mpa | Mpa | % | Mpa | Mpa | HB | mm |

| DN80-DN300 | 5 | ≥420 | ≥10 | ≥300 | ≥590 | ≤230 | 3 |

| DN350-DN600 | 4 | ≥420 | ≥10 | ≥300 | ≥590 | ≤230 | 5 |

| DN700-DN1000 | 3.2 | ≥420 | ≥10 | ≥300 | ≥590 | ≤230 | 6 |

| DN1100-DN1600 | 2.5 | ≥420 | ≥7 | ≥300 | ≥590 | ≤230 | ….. |