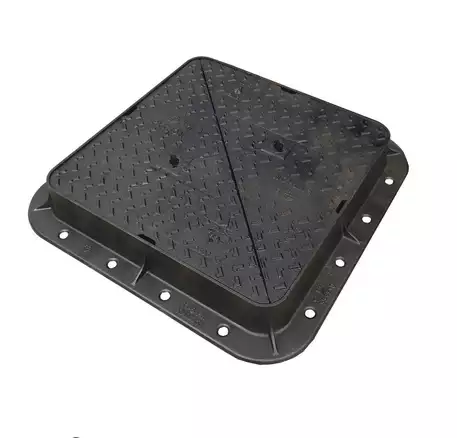

Our D400 double‑triangular cover is fully certified to BS EN 124:2015 Class D400, tested to 400 kN (40 t) static loads for main roads and carriageways. It offers a precise 600 mm clear opening within a 100 mm deep circular frame, seamlessly integrating with standard chambers and surfacing. Crafted from high‑grade ductile iron (EN GJS 400‑15), the cover and frame resist corrosion and fatigue under heavy cyclic loads. The patented double‑triangular, three‑point suspension non‑rock design prevents rattling and debris ingress, ensuring long‑term stability and quiet operation. A slip‑resistant diamond tread pattern enhances safety in wet and dry conditions. Finished with black bitumen coating and backed by BSI Kitemark certification, the frame incorporates anti‑movement technology to secure bedding material and maintain flush seating over time. Available in hinged (135°) or lift‑out configurations with ergonomic keyholes for compliant one‑man lifts, it simplifies maintenance and supports rapid access.

Technical Specifications

| Specification | Details |

|---|---|

| Standard | BS EN 124:2015 Class D400 |

| Load Capacity | 400 kN (40 tonne) |

| Clear Opening | 600 mm diameter |

| Frame Depth | 100 mm |

| Material | Ductile Iron (EN GJS 400‑15) |

| Suspension | Double-triangular, three-point non-rock design |

| Coating | Black bitumen (optional epoxy/powder coat) |

| Tread Pattern | Slip-resistant diamond pattern |

| Certification | BSI Kitemark |

| Lifting Mechanism | Hinged (135°) or lift-out; ergonomic keyholes |

Key Features

Robust Load Class

Engineered and tested to BS EN 124:2015 D400 standards, sustaining 400 kN loads for highways and busy urban environments.

Precision Fit

A precise 600 mm diameter aperture in a 100 mm deep circular frame accommodates standard chambers, ensuring flush installation and minimal surfacing build‑up.

Premium Ductile Iron

Manufactured from EN GJS 400‑15 ductile iron, the cover and frame resist corrosion, cracking, and fatigue under cyclic loading.

Non‑Rock Stability

Unique double‑triangular three‑point suspension prevents cover movement and noise, enhancing structural stability and public comfort.

Slip‑Resistant Surface

Diamond tread pattern meets slip‑resistance requirements, providing enhanced grip for pedestrians and vehicles in all weather conditions.

Secure Bedding

Anti‑movement frame technology locks bedding material in place, preserving road integrity and preventing subsidence over time.

Certified Quality

BSI Kitemark certified and black‑bitumen coated as standard, with optional epoxy or powder‑coat finishes to suit project aesthetics.

Ergonomic Handling

Available hinged (135° opening for safety) or lift‑out design; strategically placed keyholes allow compliant one‑man lifting under EN 13155 regulations.

Applications

-

Main Roads & Carriageways: Engineered for heavy traffic zones and emergency routes.

-

Industrial & Distribution Sites: Withstands forklift and delivery vehicle loads.

-

Commercial Car Parks: Delivers strength and safety for public parking areas.

-

Urban Streets & Plazas: Flush integration preserves aesthetic continuity.

Installation & Maintenance

-

Drop‑In Frame: Place the 100 mm deep frame into a prepared round aperture with minimal bedding mortar.

-

Hinged Models: Secure cover with integrated hinges—opening locks at 135° for safe one‑man operation.

-

Lift‑Out Variants: Use standard D400 lifting keys in ergonomic keyholes for fast, compliant removal.

-

Maintenance: Inspect periodically; reapply bitumen touch‑up or chosen finish to extend service life.

Why Choose Our D400 Double Triangular Cover?

Combining industry‑leading non‑rock technology, slip‑resistant surfaces, and ductile‑iron durability, our cover ensures long‑term infrastructure reliability and safety. Backed by BSI Kitemark certification and global supply support, it represents a future‑proof investment for trafficked environments. For custom badging, specialized coatings, or project-specific technical assistance, contact our engineering team for bespoke solutions and rapid delivery.

| Family: | Municipal |

| Packaging Qty: | 10 |

| Product Type: | Access Covers |

| Certified Class: | D400 |

| Standards: | EN124 |

| Surface Finish: | Anti-slip surface |

| Clear Opening: | 600 mm |

| Flange Outer Length: | 750 mm |

| Flange Outer Width: | 750 mm |

| Frame Height: | 100 mm |

| Weight: | 73 kg |

| Watertight: | No |

| Cover/Grating Shape: | Double Triangular |

| Cover/Grating Length: | 590 mm |

| Hinged: | No |

| Opening Direction: | Vertical |

| Frame Style: | Monoblock as Cast |

| Frame Shape on Vertical Section: | Flat |

| Frame Surface Protection By: | Water-Based Paint |

| Nb Anchoring Hole: | 16 |

| Installation Type: | To Concrete Pre Cast |

| Installation On: | Concrete Clear Dia 650mm Maxi |

| Handling Key: | CLE BA1 BS / 511793 |

| Locking Key: | N/A |

Ductile iron manhole cover specifications and parameters

| Parameter | Specification/Value |

|---|---|

| Material | Ductile Cast Iron (Grade 500-7) |

| Standard Compliance | EN 124, BS 497, ASTM A536, ISO 1083 |

| Shape | Round, Square, Oval |

| Load Rating | A15, B125, C250, D400, E600, F900 (EN 124 load classes) |

| Load Bearing Capacity | 1.5 – 90 tons (depending on the rating) |

| Size (Diameter/Length) | 300mm – 1500mm (depending on type and design) |

| Thickness of Lid | 20mm – 60mm (depending on the load class) |

| Weight | 10 kg to 150 kg (depending on size and class) |

| Cover Surface | Smooth, Anti-slip, Textured for grip |

| Corrosion Resistance | Excellent, with epoxy coatings or bituminous treatment |

| Gasket Type | Rubber, Neoprene, EPDM |

| Sealing Mechanism | Bolt-down, Locking system, Hinged |

| Drainage Holes | Yes, optional (for water drainage) |

| Coating Type | Bitumen coated, Epoxy coating, Hot-dip galvanizing |

| Temperature Resistance | -30°C to +150°C (depending on coating type) |

| Fire Resistance | Flame-retardant (meets local standards for fire resistance) |

| Noise Level | Low noise design for urban areas |

| Ventilation | Optional vented covers for gas or sewage systems |

| Color | Black, Gray, Custom colors available |

| Manufacturing Process | Sand casting, Lost wax casting, Centrifugal casting |

| Edge Type | Flat, Raised, Beveled, or Reinforced edges |

| Bearing Surface | Cast iron, Epoxy, Stainless Steel (optional) |

| Longevity | 50+ years with proper maintenance |

| Environmental Compliance | RoHS, REACH, and other regional environmental standards |