Calculating the weight of ductile iron pipes may seem straightforward, but several variables must be considered, including pipe dimensions, wall thickness, material properties, and pipe length.

1. Understanding Ductile Iron Pipe

Ductile iron pipes are made by adding small amounts of alloying elements, such as magnesium, to molten iron. This process enhances the strength, toughness, and flexibility of the material, making ductile iron an ideal choice for a wide range of applications, particularly in water and sewer systems.

Material Properties of Ductile Iron:

-

Density: The density of ductile iron is typically around 7.0 – 7.3 g/cm³, which affects the calculation of its weight.

-

Strength: Ductile iron pipes are known for their tensile strength, which ranges from 350 to 700 MPa, depending on the grade and manufacturing process.

-

Flexibility: Unlike cast iron, ductile iron can withstand higher levels of bending and deformation without breaking.

2. Factors Affecting the Weight of Ductile Iron Pipes

The weight of ductile iron pipes can be influenced by several factors, which must be taken into account during the calculation process.

Pipe Diameter:

The diameter of the pipe is one of the primary variables influencing the weight. Larger diameters will naturally result in heavier pipes.

Wall Thickness:

The wall thickness of the pipe is a crucial factor. Thicker walls will increase the overall weight of the pipe, as more material is required.

Pipe Length:

Longer pipes will, obviously, weigh more than shorter pipes, assuming all other factors remain constant.

Material Density:

The density of the ductile iron material used in the pipes may vary slightly depending on the manufacturing process and the alloy mix.

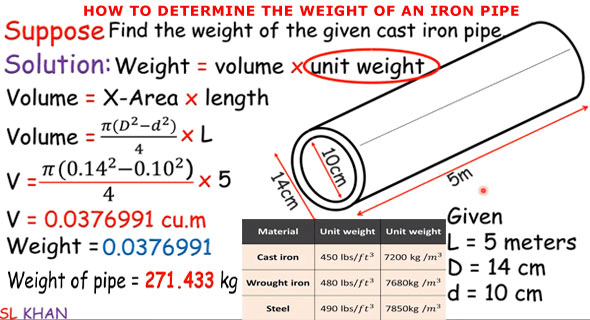

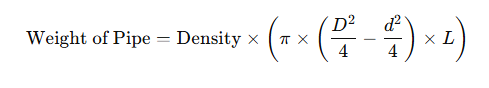

3. Basic Formula for Weight Calculation

To calculate the weight of a ductile iron pipe, the following formula is typically used:

Where:

-

DDD = Outer diameter of the pipe (in meters)

-

ddd = Inner diameter of the pipe (in meters)

-

LLL = Length of the pipe (in meters)

-

π\piπ = 3.14159

-

Density\text{Density}Density = Density of ductile iron (typically 7.0 g/cm³ or 7000 kg/m³)

Step-by-step Calculation:

-

Calculate the area of the pipe’s cross-section by subtracting the area of the inner circle from the outer circle.

-

Multiply this area by the length of the pipe.

-

Multiply the result by the material density to get the weight.

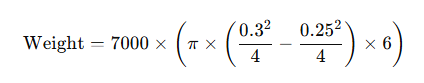

4. Detailed Weight Calculation Examples

Example 1: Standard Pipe Dimensions

Let’s calculate the weight of a ductile iron pipe with the following specifications:

-

Outer Diameter D=0.3 mD = 0.3 \, mD=0.3m

-

Inner Diameter d=0.25 md = 0.25 \, md=0.25m

-

Length L=6 mL = 6 \, mL=6m

-

Density ρ=7000 kg/m3\rho = 7000 \, kg/m^3ρ=7000kg/m3

Using the formula:

Example 2: Non-standard Pipe Dimensions

For a pipe with a larger diameter and increased wall thickness, such as:

-

Outer Diameter D=0.5 mD = 0.5 \, mD=0.5m

-

Inner Diameter d=0.4 md = 0.4 \, md=0.4m

-

Length L=12 mL = 12 \, mL=12m

-

Density ρ=7000 kg/m3\rho = 7000 \, kg/m^3ρ=7000kg/m3

5. Using Standard Tables for Weight Calculation

While formulas are essential, many manufacturers provide standard weight tables based on common pipe sizes and classes. These tables allow for quick and accurate weight estimation without having to perform manual calculations.

6. Weight Calculation for Different Pipe Classes

Ductile iron pipes are classified into different classes based on their wall thickness and pressure rating. The weight calculation varies slightly depending on the pipe class. Here’s an example comparison:

| Pipe Class | Wall Thickness (mm) | Weight per Meter (kg) |

|---|---|---|

| Class 50 | 5.0 | 40 |

| Class 52 | 6.0 | 45 |

| Class 54 | 7.0 | 50 |

7. Common Challenges in Pipe Weight Calculation

Non-standard Shapes:

While most ductile iron pipes have a standard cylindrical shape, non-standard shapes can pose challenges in weight calculations. These shapes may include fittings or pipes with varying diameters and wall thicknesses.

Variability in Material Density:

Material density can slightly vary depending on the manufacturer and the specific alloy composition used in the pipe. This variability can result in small discrepancies in the calculated weight.

8. Practical Considerations

How Weight Affects Transportation:

The weight of ductile iron pipes can impact transportation logistics, including the number of pipes that can be shipped in a single load and the required lifting equipment for installation.

Installation Tips Based on Pipe Weight:

Heavier pipes require stronger lifting equipment and careful planning during installation. Additionally, installation teams must be aware of the weight to ensure they are using proper tools and safety measures.

9. Frequently Asked Questions

Q1: What is the standard weight of a ductile iron pipe per meter?

Answer: The weight of a ductile iron pipe varies depending on the pipe’s size and class. For example, a Class 50 ductile iron pipe with a diameter of 200 mm and a wall thickness of 5 mm weighs around 25 kg per meter, while a Class 54 pipe of the same size can weigh up to 30 kg per meter.

Q2: How does the wall thickness affect the weight of ductile iron pipes?

Answer: The wall thickness directly impacts the weight of ductile iron pipes. Thicker walls mean more material is used, resulting in a higher weight per meter. The added weight also contributes to increased strength and durability.

Q3: Can I use standard weight tables for non-standard pipe sizes?

Answer: Standard weight tables are most effective for commonly used pipe sizes. For non-standard pipe sizes or custom fittings, it’s best to calculate the weight using the formula provided earlier or consult with the manufacturer for specific weight information.

Q4: Why is it important to know the weight of a ductile iron pipe before installation?

Answer: Knowing the weight of the pipe before installation is crucial for ensuring proper handling, transport, and storage. It also helps in determining the correct lifting equipment and safety measures to avoid accidents or damage during installation.

Q5: Can the density of ductile iron pipes vary between manufacturers?

Answer: Yes, the density of ductile iron can vary slightly depending on the alloy composition and manufacturing process used by different manufacturers. This may affect the calculated weight, though the difference is generally minimal.

Q6: Are there any specific challenges when calculating the weight of large-diameter ductile iron pipes?

Answer: Large-diameter pipes present additional challenges, such as the need for specialized equipment to handle and transport them. The weight calculation itself may not change, but practical considerations such as logistics, lifting techniques, and installation processes become more complex.

10. Conclusion

Calculating the weight of ductile iron pipes is an essential task for engineers, contractors, and those involved in water distribution and sewer systems. By understanding the variables that impact the weight, using the right formulas, and referring to standard tables, you can ensure accurate weight estimation for proper handling, transportation, and installation.

References:

- Ductile Iron – Wikipedia

- ASTM A536 Standard Specification for Ductile Iron Castings – ASTM International

- AWWA Standards for Ductile Iron Pipe and Fittings – American Water Works Association

- Density of Materials – Engineering Toolbox

- ISO 2531: Ductile iron pipes, fittings, accessories and their joints for water applications – International Organization for Standardization (ISO)