Class 52 ductile iron pipes are widely used in water and wastewater infrastructure due to their strength, durability, and resistance to corrosion. The weight of these pipes is a critical factor in various stages of their lifecycle, including transportation, installation, and long-term maintenance.

1. What is Class 52 Ductile Iron Pipe?

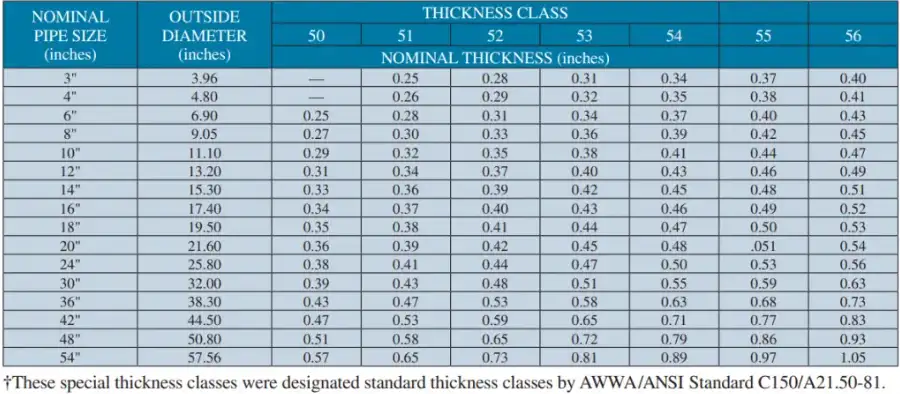

Class 52 ductile iron pipes are manufactured according to the American Water Works Association (AWWA) C151 standard. The “52” denotes the pipe’s thickness class, indicating a wall thickness designed to withstand a pressure of 350 psi. These pipes are commonly used in municipal water systems, fire protection lines, and other applications requiring high-pressure capabilities.

2. Factors Influencing the Weight of Class 52 Ductile Iron Pipes

2.1 Pipe Diameter

The diameter of the pipe directly impacts its weight. Larger diameter pipes require more material, thus increasing their weight.

2.2 Wall Thickness

Class 52 pipes have a specific wall thickness designed for 350 psi pressure. Variations in wall thickness can affect the overall weight of the pipe.

2.3 Length of the Pipe

Standard lengths for ductile iron pipes are typically 18 or 20 feet. Longer pipes will naturally weigh more due to the increased material.

2.4 Coatings and Linings

Ductile iron pipes are often coated and lined to prevent corrosion. Common coatings include cement mortar and epoxy. These coatings add to the overall weight of the pipe.

3. Standard Weight Specifications

According to McWane Ductile, the average weight per foot for various pipe sizes in Class 52 is as follows:

| Pipe Size (Inches) | Weight per Foot (lbs) |

|---|---|

| 3 | 9.90 |

| 4 | 12.60 |

| 6 | 19.60 |

| 8 | 22.80 |

| 10 | 31.00 |

| 12 | 39.00 |

| 14 | 48.00 |

| 16 | 57.00 |

| 18 | 66.00 |

| 20 | 75.00 |

These weights are approximate and can vary based on specific manufacturer specifications and coating types.

4. Practical Implications of Pipe Weight

4.1 Transportation

The weight of ductile iron pipes affects transportation logistics. Heavier pipes require more robust vehicles and may incur higher shipping costs. It’s essential to consider the total weight when planning transportation to ensure compliance with road weight limits and to optimize delivery efficiency.

4.2 Installation

Handling and installing heavy pipes necessitate specialized equipment and trained personnel. The weight influences the choice of lifting devices, trenching methods, and the overall timeline of the installation process.

4.3 Structural Support

The weight of the pipe affects the design of supports and anchors. Adequate support structures must be in place to prevent sagging, movement, or potential damage to the pipe during operation.

5. Comparison with Other Pipe Classes

| Pipe Size (Inches) | Class 50 Weight per Foot (lbs) | Class 52 Weight per Foot (lbs) | Class 53 Weight per Foot (lbs) |

|---|---|---|---|

| 3 | 8.00 | 9.90 | 11.00 |

| 4 | 10.00 | 12.60 | 14.00 |

| 6 | 15.00 | 19.60 | 22.00 |

| 8 | 20.00 | 22.80 | 25.00 |

| 10 | 28.00 | 31.00 | 34.00 |

| 12 | 36.00 | 39.00 | 42.00 |

| 14 | 44.00 | 48.00 | 51.00 |

| 16 | 52.00 | 57.00 | 60.00 |

| 18 | 60.00 | 66.00 | 69.00 |

| 20 | 68.00 | 75.00 | 78.00 |

This comparison illustrates the incremental increase in weight as the class number rises, indicating thicker walls and higher pressure ratings.

6. Frequently Asked Questions (FAQs)

6.1 What is the standard length of a Class 52 ductile iron pipe?

Standard lengths for Class 52 ductile iron pipes are typically 18 or 20 feet. However, custom lengths can be manufactured based on project requirements.

6.2 How does the wall thickness affect the weight of the pipe?

The wall thickness determines the pipe’s pressure rating and strength. Thicker walls increase the pipe’s weight due to the additional material required.

6.3 Are there variations in weight among different manufacturers?

Yes, slight variations in weight can occur due to differences in manufacturing processes, material specifications, and coating applications. It’s essential to consult the manufacturer’s data sheets for precise weight information.

6.4 How does the coating affect the pipe’s weight?

Coatings such as cement mortar or epoxy are applied to prevent corrosion and enhance durability. These coatings add to the overall weight of the pipe.

6.5 Why is it important to know the weight of a ductile iron pipe?

Knowing the weight is crucial for transportation planning, installation procedures, and structural support design. It ensures that the appropriate equipment is used and that safety and efficiency are maintained during handling and installation.

6.6 Can the weight of a ductile iron pipe vary between manufacturers?

Yes, the weight of a ductile iron pipe can vary between manufacturers due to differences in manufacturing processes, material specifications, and coating applications. It’s important to consult the manufacturer’s data sheets for precise weight information.

7. Conclusion

Understanding the weight of Class 52 ductile iron pipes is essential for various aspects of infrastructure planning and development. Factors such as pipe diameter, wall thickness, length, and coatings all influence the overall weight. By considering these factors, professionals can ensure efficient transportation, safe installation, and adequate structural support for ductile iron pipelines.