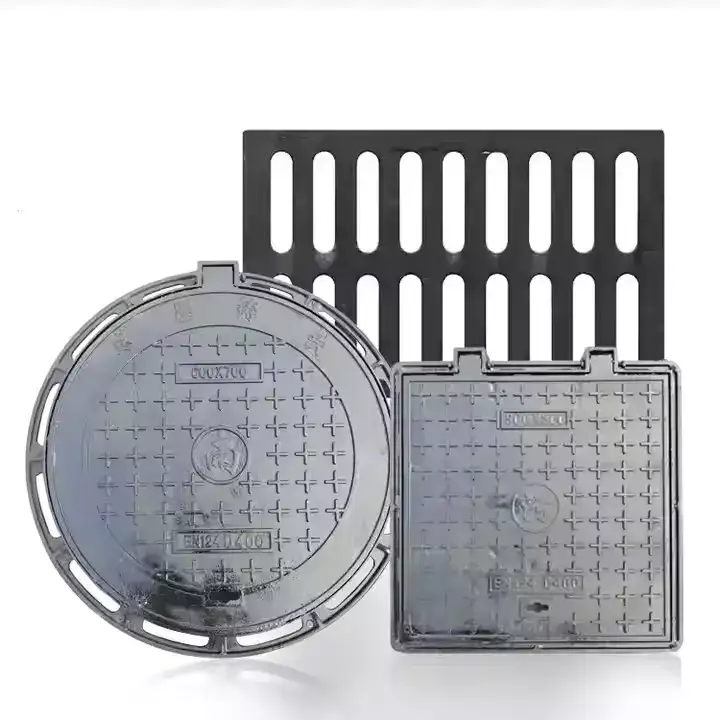

Manhole covers are essential components of urban infrastructure, providing access to underground utilities and ensuring safety. The weight of a manhole cover is influenced by factors such as size, material, and intended use. This article delves into the specifics of 32-inch manhole covers, addressing common questions and providing detailed information for professionals and enthusiasts alike.

1. Understanding Manhole Cover Weights

1.1 Standard Weights for 32-Inch Manhole Covers

The weight of a 32-inch manhole cover varies based on its material and design. For instance, a standard cast iron cover of this size typically weighs between 100 to 300 pounds. However, variations exist depending on the specific requirements and standards applied.

1.2 Factors Influencing Weight

-

Material: Cast iron covers are heavier compared to composite materials.

-

Design: Solid covers are generally heavier than vented or perforated ones.

-

Load Classification: Covers designed for vehicular traffic are heavier than those intended for pedestrian areas.

2. Material Composition and Its Impact on Weight

2.1 Cast Iron

Cast iron is a traditional material known for its durability and strength. A 32-inch cast iron manhole cover typically weighs between 150 to 250 pounds. This weight ensures the cover remains securely in place under heavy traffic conditions.

2.2 Ductile Iron

Ductile iron offers enhanced strength and ductility compared to cast iron. A 32-inch ductile iron cover may weigh slightly less than its cast iron counterpart while maintaining similar load-bearing capacity.

2.3 Composite Materials

Composite manhole covers, made from materials like fiberglass or polymer, are lighter and resistant to corrosion. These covers are ideal for areas requiring frequent access and where weight is a concern.

3. Load Classifications and Standards

3.1 EN 124 Standard

The European standard EN 124 classifies manhole covers based on their load-bearing capacity. For example, a Class D400 cover can withstand up to 400 kN, suitable for areas with heavy vehicular traffic.

3.2 AASHTO M306

In the United States, the American Association of State Highway and Transportation Officials (AASHTO) provides standards for manhole covers. These standards ensure that covers meet specific load and safety requirements.

4. Manufacturing Processes

4.1 Casting

Traditional manhole covers are produced through casting, where molten metal is poured into molds to form the desired shape. This process is common for cast and ductile iron covers.

4.2 Compression Molding

Composite covers are often manufactured using compression molding, where material is placed into a mold and subjected to heat and pressure to form the cover.

5. Applications of 32-Inch Manhole Covers

5.1 Urban Infrastructure

32-inch manhole covers are commonly used in urban settings to provide access to sewer systems, electrical vaults, and other underground utilities.

5.2 Industrial Sites

In industrial areas, these covers are used to access equipment pits and maintenance shafts, ensuring safety and functionality.

6. Frequently Asked Questions (FAQs)

6.1 Why are manhole covers round?

Round manhole covers are used because a round shape cannot fall through its opening, unlike square or rectangular covers. This design ensures safety and ease of handling.

6.2 How do I determine the load classification needed?

The required load classification depends on the expected traffic load. For pedestrian areas, a Class A15 cover may suffice, while areas with heavy vehicular traffic may require a Class D400 cover.

6.3 Are composite manhole covers as durable as metal ones?

Yes, composite manhole covers are designed to be durable and resistant to corrosion. They are often used in areas where weight and corrosion resistance are priorities.

6.4 How often should manhole covers be inspected?

Regular inspections are recommended to ensure the integrity of manhole covers. The frequency depends on the location and traffic conditions but should be at least annually.

6.5 Can manhole covers be customized?

Yes, manhole covers can be customized with logos, designs, or specific load classifications to meet particular requirements.

6.6 What maintenance is required for manhole covers?

Maintenance includes regular inspections for cracks or damage, cleaning to remove debris, and ensuring that the cover fits securely in its frame.

7. Conclusion

Understanding the weight, material composition, and standards associated with 32-inch manhole covers is crucial for selecting the appropriate cover for specific applications. By considering factors such as load classification and manufacturing processes, professionals can ensure the safety and functionality of urban infrastructure.

References:

- EN 124: Specification for Manhole Covers and Gully Tops – European Committee for Standardization (CEN)

- AASHTO M306 – Standard Specification for Manhole Frames and Covers – American Association of State Highway and Transportation Officials

- ASTM Standards on Cast and Ductile Iron – ASTM International

- Manhole Cover – Wikipedia

- Bridge and Roadway Load Classifications – Federal Highway Administration (FHWA)