Sizing a ductile iron tapping tee is a critical task in pipeline construction and maintenance. An appropriately sized tapping tee ensures a secure and leak-free connection, maintaining the integrity and efficiency of the entire system. This guide aims to provide engineers and contractors with the necessary knowledge to accurately size tapping tees for various applications.

Understanding Tapping Tees

1 Definition and Purpose

A tapping tee is a fitting used to create a branch connection on an existing pipeline without interrupting the flow. It allows for the installation of valves, hydrants, or other equipment, facilitating system expansion or maintenance.

2 Components of a Tapping Tee

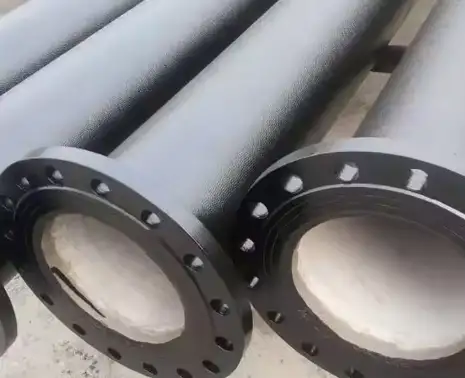

A typical ductile iron tapping tee comprises:

-

Body: The main structure, usually made of ductile iron, providing strength and durability.

-

Outlet: The branch connection, which can be flanged, threaded, or grooved, depending on the application.

-

Gaskets: Sealing elements that prevent leaks between the tee and the existing pipe.

-

Bolts and Nuts: Fasteners used to secure the tee to the existing pipe.

Factors Influencing Tapping Tee Sizing

1.Pipe Diameter

The diameter of the existing pipe is a fundamental factor in determining the size of the tapping tee. Common ductile iron pipe sizes range from 3 inches to 64 inches. The tapping tee must match the outside diameter (OD) of the existing pipe to ensure a proper fit.

2.Pressure Rating

The pressure rating of the tapping tee should align with the operating pressure of the pipeline. Most ductile iron tapping tees are designed to handle pressures up to 250 psi, but higher-rated tees are available for specific applications.

3.Wall Thickness

The wall thickness of the existing pipe affects the type of tapping method used. Thicker walls can accommodate larger taps, while thinner walls may require special considerations to prevent damage.

4.Material Compatibility

Ensure that the material of the tapping tee is compatible with the existing pipe material to prevent galvanic corrosion and ensure a secure connection.

Sizing Methodology

1.Step-by-Step Guide

-

Measure the Outside Diameter (OD): Use calipers or a tape measure to determine the OD of the existing pipe.

-

Determine the Pressure Rating: Identify the operating pressure of the pipeline.

-

Select the Appropriate Tapping Tee: Choose a tee that matches the OD and pressure rating.

-

Verify Wall Thickness Compatibility: Ensure the tee can accommodate the wall thickness of the existing pipe.

2.Calculation Examples

Example 1:

-

Existing Pipe OD: 8 inches

-

Operating Pressure: 150 psi

-

Wall Thickness: 0.25 inches

A suitable tapping tee would be an 8-inch ductile iron tee with a pressure rating of at least 150 psi and compatible wall thickness.

Example 2:

-

Existing Pipe OD: 12 inches

-

Operating Pressure: 200 psi

-

Wall Thickness: 0.375 inches

Select a 12-inch ductile iron tapping tee with a pressure rating of 200 psi and compatible wall thickness.

Comparison of Tapping Tee Sizes

| Pipe Size (inches) | Tapping Tee Size (inches) | Pressure Rating (psi) | Wall Thickness (inches) |

|---|---|---|---|

| 6 | 6 | 250 | 0.25 |

| 8 | 8 | 250 | 0.25 |

| 10 | 10 | 250 | 0.375 |

| 12 | 12 | 250 | 0.375 |

| 16 | 16 | 250 | 0.5 |

| 20 | 20 | 250 | 0.5 |

Installation Considerations

1.Site Assessment

Conduct a thorough site assessment to determine the location of the existing pipe, accessibility, and any potential obstacles that may affect the installation process.

2.Tools and Equipment

Ensure that all necessary tools and equipment are available, including tapping machines, wrenches, gaskets, and bolts.

3.Safety Protocols

Follow all safety protocols, including wearing appropriate personal protective equipment (PPE) and ensuring that the work area is secure.

Maintenance and Inspection

Regular maintenance and inspection of tapping tees are essential to ensure their continued performance. Check for signs of wear, corrosion, or leaks, and replace components as necessary.

Case Studies

Case Study 1:

In a municipal water distribution system, a 12-inch ductile iron pipe required a new branch connection. A 12-inch tapping tee with a pressure rating of 250 psi was selected and successfully installed, providing a secure and leak-free connection.

Case Study 2:

During the expansion of a fire protection system, a 16-inch ductile iron pipe needed a new outlet. A 16-inch tapping tee with a pressure rating of 250 psi was chosen, and the installation was completed without issues, ensuring the system’s integrity.

Frequently Asked Questions (FAQs)

Q1: What is the maximum size of a tapping tee for ductile iron pipe?

The maximum size of a tapping tee depends on the pipe diameter and wall thickness. For ductile iron pipes 24 inches and larger, direct taps up to 2 inches are generally acceptable. However, larger taps may require special considerations and equipment.

Q2: Can tapping tees be used on all types of ductile iron pipes?

Yes, tapping tees are compatible with all classes of ductile iron pipes. However, the wall thickness must be sufficient to accommodate the tap size.

Q3: How do I determine the appropriate pressure rating for a tapping tee?

The pressure rating of the tapping tee should match or exceed the operating pressure of the existing pipeline. Ensure that the selected tee is rated for the specific application.

Q4: What tools are required for installing a ductile iron tapping tee?

Essential tools include a tapping machine, wrenches, gaskets, bolts, and safety equipment. Ensure that all tools are in good condition and suitable for the task.

Q5: Are there any special considerations for installing tapping tees in high-pressure systems?

Yes, high-pressure systems may require tapping tees with higher pressure ratings and additional reinforcement. Consult manufacturer specifications and industry standards for guidance.

Q6: How can I ensure a leak-free connection when installing a tapping tee?

Proper installation is key to preventing leaks. Ensure that gaskets are correctly positioned, bolts are tightened to the specified torque, and all components are compatible and in good condition.

Conclusion

Accurately sizing and installing a ductile iron tapping tee is essential for maintaining the integrity and efficiency of a pipeline system. By considering factors such as pipe diameter, pressure rating, wall thickness, and material compatibility, engineers and contractors can ensure a secure and reliable connection. Regular maintenance and inspection further contribute to the long-term performance of the system.

References:

- Ductile Iron Pipe – Wikipedia

- American Water Works Association (AWWA) Standards C110 & C153 for Ductile Iron Pipe and Fittings

- ISO 2531: Ductile Iron Pipes, Fittings, Accessories, and Their Joints for Water Applications

- EN 545: Ductile Iron Pipes, Fittings, and Accessories – Requirements and Tests

- U.S. Environmental Protection Agency (EPA) – Water Infrastructure Research and Standards