Ductile iron pipes (DIP) have been a staple in infrastructure projects for many decades due to their strength, durability, and corrosion resistance. One of the most critical aspects to understand when selecting ductile iron pipes is the inside diameter (ID), which determines the flow capacity, pressure rating, and suitability for various applications.

This guide will walk you through the details of ductile iron pipe inside diameters, how to interpret diameter charts, and the factors influencing pipe selection. Additionally, we’ll cover industry standards, provide a detailed chart for quick reference, and answer common questions regarding ductile iron pipe sizing.

1. What is the Inside Diameter of Ductile Iron Pipe?

The inside diameter (ID) of ductile iron pipe refers to the internal measurement of the pipe, which directly affects the flow rate and pressure capacity. It’s a key specification for engineers and contractors when designing and installing piping systems. A larger inside diameter allows more fluid to flow through, while a smaller ID is used for applications requiring higher pressure or less fluid movement.

In ductile iron pipes, the ID is critical for determining the pipe’s compatibility with fittings, valves, and other components in the pipeline system. It’s also essential for maintaining the system’s hydraulic performance.

2. Ductile Iron Pipe Sizing and Standards

Ductile iron pipe sizes are usually described by their nominal diameter (DN) or pipe size. The nominal size refers to the approximate diameter of the pipe, which can be used in conjunction with the inside diameter to ensure compatibility with the rest of the system.

2.1. Standard Nominal Sizes

Ductile iron pipes are available in various nominal sizes, with the most common being:

-

3 inches to 24 inches: Small to medium-sized systems for residential and commercial use.

-

30 inches to 64 inches: Larger systems for industrial, municipal, and utility projects.

-

Above 64 inches: Custom or specialized pipes for large-scale infrastructure projects.

2.2. Standards for Ductile Iron Pipe Sizing

Several organizations provide guidelines for the sizing of ductile iron pipes:

-

AWWA C151: This standard from the American Water Works Association specifies the dimensions and pressure ratings for ductile iron pipes, ensuring their suitability for water distribution and other uses.

-

ISO 2531: The International Organization for Standardization provides global standards for ductile iron pipes, covering everything from material specifications to installation requirements.

-

EN 545: European standards for ductile iron pipes, focusing on pressure ratings and the physical characteristics of the pipe.

2.3. The Importance of Inside Diameter

The inside diameter determines the flow capacity, which is essential for applications where flow rates are critical. For example:

-

Water Distribution Systems: The inside diameter ensures that water can flow efficiently across long distances.

-

Wastewater Systems: The ID of the pipe affects the drainage capacity and reduces the risk of clogs or blockages.

-

Industrial Applications: The inside diameter plays a role in the transport of chemicals, oil, and gas, where fluid flow and pressure control are essential.

3. Ductile Iron Pipe Inside Diameter Chart

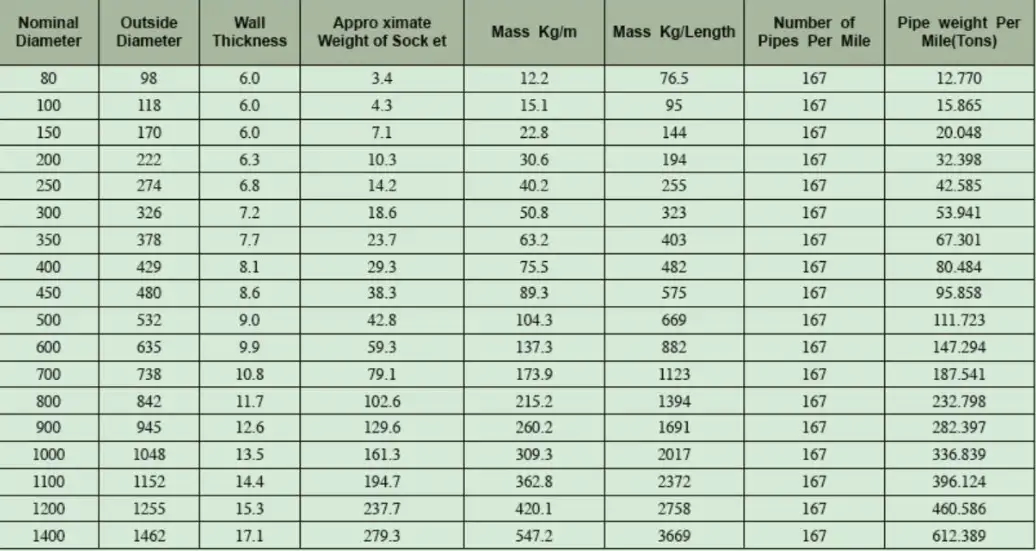

Below is a simplified chart that shows typical inside diameters for ductile iron pipes of varying nominal sizes:

| Nominal Pipe Size (inches) | Inside Diameter (inches) | Wall Thickness (inches) | Pressure Rating (psi) |

|---|---|---|---|

| 3 | 3.00 | 0.22 | 350 |

| 4 | 4.00 | 0.24 | 350 |

| 6 | 6.00 | 0.26 | 350 |

| 8 | 8.00 | 0.28 | 350 |

| 12 | 12.00 | 0.32 | 250 |

| 16 | 16.00 | 0.38 | 250 |

| 20 | 20.00 | 0.42 | 250 |

| 24 | 24.00 | 0.46 | 250 |

| 30 | 30.00 | 0.50 | 250 |

| 36 | 36.00 | 0.56 | 250 |

| 48 | 48.00 | 0.72 | 250 |

| 54 | 54.00 | 0.76 | 250 |

| 64 | 64.00 | 0.80 | 250 |

3.1. Explanation of the Chart

-

Nominal Pipe Size (NPS): This is the standardized designation of the pipe size.

-

Inside Diameter (ID): The actual inside diameter that influences the flow capacity.

-

Wall Thickness: The thickness of the pipe’s wall, which contributes to its pressure rating and durability.

-

Pressure Rating: Indicates the maximum pressure the pipe can safely handle.

This chart provides a quick reference for engineers and contractors to determine the right ductile iron pipe size for a given application.

4. Key Considerations When Selecting Ductile Iron Pipe Size

Selecting the right size of ductile iron pipe involves more than just looking at the inside diameter. Several other factors must be considered:

4.1. Flow Requirements

The inside diameter directly influences the flow rate of the system. For applications with high flow demands, such as water treatment plants or municipal water systems, larger diameters are necessary. Conversely, smaller diameters are more suitable for residential or low-pressure systems.

4.2. Pressure and Load Conditions

Pressure rating and pipe strength must match the system’s requirements. A higher pressure rating is necessary for systems exposed to extreme conditions, such as industrial applications or pipelines that experience frequent pressure surges.

4.3. Environmental Conditions

Consider the environment in which the pipe will be installed. For underground installations, additional corrosion protection may be needed. In seismic zones, the pipe’s flexibility and ability to handle ground movement should be considered.

4.4. Regulatory Standards

Ensure the selected pipe complies with local or international standards (such as AWWA C151 or ISO 2531). These standards govern material quality, joint design, and testing procedures to ensure reliable performance over the life of the pipe.

5. Frequently Asked Questions (FAQs)

1. How is the inside diameter of ductile iron pipe measured?

The inside diameter of ductile iron pipes is measured from the inner walls of the pipe, excluding the thickness of the pipe’s material. It is a crucial factor in determining the pipe’s flow capacity and is standardized for each nominal pipe size.

2. What is the difference between nominal size and inside diameter in ductile iron pipes?

The nominal size refers to the pipe’s standardized designation (such as 6 inches or 12 inches), which is a general approximation of the inside diameter. The inside diameter, however, is the actual measurement of the inner opening of the pipe, and it can vary slightly depending on the pipe wall thickness and the type of joint used.

3. How does the inside diameter affect the flow rate of a ductile iron pipe?

The inside diameter plays a direct role in the flow rate. A larger inside diameter allows more fluid to pass through the pipe, increasing the flow rate. Smaller diameters restrict the flow, making them suitable for high-pressure applications but limiting flow capacity.

4. Can ductile iron pipes with different inside diameters be connected together?

Yes, ductile iron pipes with different inside diameters can be connected using reducers, couplings, or transition fittings. These fittings ensure a smooth connection and allow for the safe and effective flow of liquids between pipes of varying sizes.

5. What are the most common applications for ductile iron pipes with larger inside diameters?

Ductile iron pipes with larger inside diameters are typically used in municipal water supply systems, sewage networks, and industrial fluid transport. They are particularly useful in systems that require high flow rates, such as fire suppression systems and large-scale water treatment plants.

Conclusion

Understanding the inside diameter of ductile iron pipes is fundamental when designing and installing pipeline systems. By referencing the ductile iron pipe inside diameter chart and considering other key factors such as pressure ratings, flow requirements, and environmental conditions, engineers can make informed decisions for their projects.