Ductile iron (nodular iron) offers a versatile range of grades tailored for industrial applications, from water infrastructure to automotive components.The classification of ductile iron into various grades is primarily based on its mechanical properties, such as tensile strength, yield strength, and elongation. These grades are standardized by organizations like ASTM International, with ASTM A536 being a widely recognized specification that outlines the mechanical requirements for ductile iron castings.

Mechanical Properties of Common Ductile Iron Grades

The mechanical properties of ductile iron vary across different grades, influencing their suitability for various applications. Below is a detailed comparison of common ductile iron grades as per ASTM A536:

| Grade | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Brinell Hardness | Typical Applications |

|---|---|---|---|---|---|

| 60-40-18 | 60,000 | 40,000 | 18 | 149-187 | Pressure pipes, fittings |

| 65-45-12 | 65,000 | 45,000 | 12 | 170-207 | Automotive components |

| 80-55-06 | 80,000 | 55,000 | 6 | 187-255 | Gears, crankshafts |

| 100-70-03 | 100,000 | 70,000 | 3 | 217-269 | High-strength applications |

| 120-90-02 | 120,000 | 90,000 | 2 | 240-300 | Heavy-duty machinery |

These grades demonstrate a trade-off between strength and ductility; as tensile and yield strengths increase, elongation tends to decrease, affecting the material’s ability to deform plastically before fracture.

Microstructure and Its Influence on Properties

The microstructure of ductile iron significantly influences its mechanical properties. The presence of spheroidal graphite nodules within the iron matrix reduces stress concentration points, enhancing ductility and impact resistance.

The matrix structure, which can be ferritic, pearlitic, or a combination of both, also affects the material’s properties:

-

Ferritic Matrix: Offers high ductility and impact resistance but lower strength and hardness.

-

Pearlitic Matrix: Provides higher strength and hardness but reduced ductility.

-

Mixed Ferritic-Pearlitic Matrix: Balances strength and ductility, suitable for a wide range of applications.

Heat treatment processes, such as annealing or austempering, can modify the matrix structure to achieve desired mechanical properties for specific applications.

Applications of Various Ductile Iron Grades

Different ductile iron grades are selected based on the specific requirements of applications across various industries:

-

Grade 60-40-18: Ideal for applications requiring high ductility and impact resistance, such as pressure pipes and fittings.

-

Grade 65-45-12: Commonly used in automotive components, agricultural machinery, and general engineering applications due to its balanced strength and ductility.

-

Grade 80-55-06: Suitable for parts subjected to higher stresses, like gears, crankshafts, and heavy-duty machinery components.

-

Grade 100-70-03 and 120-90-02: Employed in applications demanding high strength and wear resistance, such as mining equipment, heavy-duty gears, and structural components.

Selecting the appropriate grade ensures that the component will perform reliably under the expected service conditions, optimizing both performance and cost.

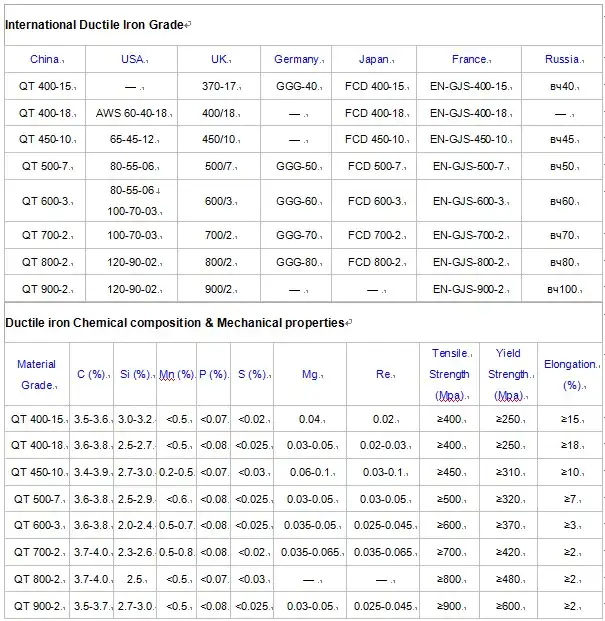

International Standards and Equivalent Grades

Ductile iron grades are standardized by various international organizations, facilitating global trade and application. Below is a comparison of equivalent grades across different standards:

| ASTM A536 Grade | ISO 1083 Grade | EN 1563 Grade | Typical Applications |

|---|---|---|---|

| 60-40-18 | 400-18 | EN-GJS-400-18 | Pressure pipes, fittings |

| 65-45-12 | 450-12 | EN-GJS-450-10 | Automotive components |

| 80-55-06 | 500-7 | EN-GJS-500-7 | Gears, crankshafts |

| 100-70-03 | 700-2 | EN-GJS-700-2 | High-strength applications |

Understanding these equivalents is essential for engineers and procurement professionals working in international contexts, ensuring compliance with local standards and specifications.

Frequently Asked Questions (FAQs)

Q1: What factors should be considered when selecting a ductile iron grade for a specific application?

A1: When selecting a ductile iron grade, consider the mechanical requirements of the application, such as tensile strength, yield strength, and elongation. Additionally, assess the operating environment, including exposure to corrosive elements, temperature variations, and mechanical stresses. The manufacturing process, cost constraints, and compliance with relevant standards should also influence the selection.

Q2: How does heat treatment affect the properties of ductile iron?

A2: Heat treatment processes, such as annealing, normalizing, and austempering, alter the microstructure of ductile iron, thereby modifying its mechanical properties. Annealing can increase ductility and reduce hardness, making the material more machinable. Austempering enhances strength and wear resistance by producing a bainitic microstructure. Selecting the appropriate heat treatment allows tailoring the material properties to specific application requirements.

Q3: Can ductile iron be welded, and does the grade affect its weldability?

A3: Ductile iron can be welded, but its weldability varies depending on the grade and microstructure. Grades with a predominantly ferritic matrix, like 60-40-18, exhibit better weldability due to their higher ductility and lower hardness. Preheating and post-weld heat treatment may be necessary to prevent cracking and ensure the integrity of the weld. It’s essential to follow appropriate welding procedures and consult relevant standards when welding ductile iron components.

Q4: How does the presence of alloying elements influence the properties of ductile iron?

A4: Alloying elements such as silicon, manganese, nickel, and copper can significantly influence the mechanical properties and microstructure of ductile iron. For instance, silicon promotes a ferritic matrix, enhancing ductility, while manganese and nickel can increase strength and hardness by promoting a pearlitic structure. The careful control of these elements during the manufacturing process allows for the customization of ductile iron properties to meet specific application needs.

Q5: What are the advantages of using ductile iron over other materials like steel or gray cast iron?

A5: Ductile iron offers a unique combination of strength, ductility, and cost-effectiveness. Compared to gray cast iron, it has superior impact resistance and tensile strength due to its nodular graphite microstructure. While steel may offer higher strength, ductile iron is more economical and provides adequate performance for many applications. Additionally, ductile iron has excellent machinability and good wear resistance, making it a versatile material choice across various industries.