Ductile iron companion flanges (also called companion or backing flanges) are essential components for creating threaded or mechanical connections in waterworks, irrigation, and industrial piping systems. Manufactured to stringent standards such as ANSI/AWWA C110/A21.10 and ASME B16.1, they provide reliable bolt-on connections that mate with lap-joint flanges or hub ends on ductile iron pipe.

1. Introduction to Ductile Iron Companion Flanges

Ductile iron companion flanges serve as loose, mating flanges that bolt onto the end of lap-joint (long-slip) or plain-end ductile iron pipe. Unlike welded or integrally cast flanges, companion flanges slide over the pipe end, allowing rotation for bolt alignment without rotating the pipe itself . They are typically used in water distribution, fire protection, and industrial systems where ease of assembly and maintenance is paramount.

2. Material Properties and Applicable Standards

2.1 Ductile Iron (ASTM A536)

Companion flanges are cast from ductile iron conforming to ASTM A536 (Grade 65-45-12), offering high tensile strength (65 000 psi), excellent ductility, and impact resistance. The nodular graphite microstructure ensures toughness under cyclic loads and pressure surges.

2.2 Flange Standards

-

ANSI/AWWA C110/A21.10: Covers dimensions, tolerances, and coatings for cast iron companion and other flanged fittings up to 64″ diameter.

-

ASME B16.1: Specifies Class 125 and Class 250 cast iron flanges; companion flanges are commonly rated Class 125 for water service.

-

ANSI/AWWA C207: Applies to ductile iron flanges for mechanical joints; companion flanges must mate correctly with these flanges for system compatibility.

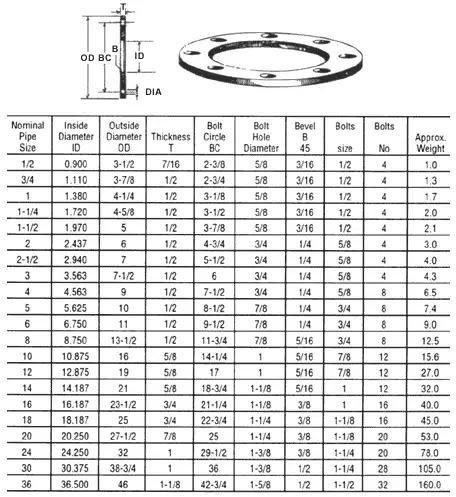

3. Dimensional Standards and Comparison

The dimensions of companion flanges vary slightly between ANSI/AWWA C110 and ASME B16.1. The table below compares key dimensions for nominal pipe sizes (NPS) 2″–12″.

| NPS (in) | Bolt Circle Dia. (in) | No. of Holes | Hole Dia. (in) | Raised Face OD (in) | OD (in) ANSI/AWWA C110 | OD (in) ASME B16.1 |

|---|---|---|---|---|---|---|

| 2 | 4.75 | 4 | 0.625 | 3.75 | 6.25 | 6.00 |

| 4 | 7.50 | 4 | 0.625 | 5.50 | 8.00 | 7.50 |

| 6 | 9.50 | 8 | 0.750 | 8.00 | 10.75 | 10.00 |

| 8 | 12.00 | 8 | 0.750 | 10.00 | 13.50 | 13.00 |

| 10 | 14.00 | 8 | 0.875 | 12.00 | 15.50 | 15.00 |

| 12 | 16.00 | 8 | 0.875 | 14.00 | 17.50 | 17.00 |

Table: ANSI/AWWA C110 vs. ASME B16.1 companion flange dimensions

4. Size Range and Pressure Ratings

Companion flanges are available in sizes from 2″ up to 64″ for waterworks applications. Standard pressure classes include:

-

Class 125 (150 psi): Most common for potable water and fire protection.

-

Class 250 (250 psi): Available for high-pressure systems, but less common; note that Class 125 and Class 250 are not interchangeable due to differing bolt patterns.

5. Flange Types and Variations

5.1 Threaded Companion Flange

Threaded for NPT pipe (per ASME B1.20.1), these flanges screw onto the male threaded end of the pipe. They are quick-to-install and ideal for repair and retrofit applications.

5.2 Blind Companion Flange

Blank, solid flanges used to cap off pipe ends during shutdowns or testing. Available with optional 2″ test taps per ANSI/AWWA C110.

5.3 Reducing Companion Flange

Flanges with different hub and flange bore diameters allow connecting pipes of differing sizes (e.g., 5″ × 11″ reducing flange).

6. Manufacturing Process

Companion flanges are produced via sand-casting or shell-molding. Key steps include:

-

Pattern creation: Machined patterns per standard templates (125 lb drilling).

-

Molding and pouring: Molten ductile iron poured into molds, then solidified.

-

Heat treatment: Ensures spheroidal graphite structure and mechanical properties per ASTM A536.

-

Machining: Finish-machining bolt holes, sealing faces, and threads per ASME B16.1 and B1.20.1.

-

Coating: Asphaltic or epoxy primers (e.g., Tnemec Pota-Pox N140) for corrosion protection.

7. Installation and Maintenance

-

Gasket selection: Use resilient gaskets rated for intended pressure; compressed on raised face areas.

-

Bolt tightening: Follow star-pattern sequence, torque to manufacturer’s specifications (typically 75–125 ft-lb for Class 125) to ensure uniform seal.

-

Inspection: Regular checks for corrosion, bolt torque, and gasket condition.

-

Repair: Companion flanges can be unbolted and replaced without disturbing pipe alignment.

8. Corrosion Protection and Coatings

To extend service life in buried or corrosive environments, companion flanges receive:

-

Internal coating: Cement-mortar lining per ANSI/AWWA C104/A21.4 for potable water.

-

External coating: Asphaltic or epoxy primers (e.g., Tnemec Pota-Pox N140-1211) applied after blast cleaning to SSPC-SP-10.

-

Cathodic protection: Recommended for aggressive soils, using sacrificial anodes or impressed-current systems.

9. Pricing Factors and Cost Analysis

Price drivers include:

| Factor | Influence on Price |

|---|---|

| Size (NPS) | Larger diameters require more material and machining |

| Pressure Class | Class 250 flanges cost ~15–25% more than Class 125 |

| Coating Type | Epoxy coatings add 10–20% to base cast cost |

| Threading vs. Blind | Threading requires additional machining and inspection |

| Order quantity | Bulk orders often receive 10–15% volume discounts |

Table: Key pricing factors for ductile iron companion flanges

Example street prices (U.S.A., single-piece, Class 150):

| NPS (in) | Threaded FF (MSRP) | Now (USD) |

|---|---|---|

| 2 | — | 36.02 |

| 4 | — | 73.13 |

| 10 | 58.21 | 68.97 |

Source: BuyFittingsOnline

10. Market Availability and Major Suppliers

Leading suppliers of ductile iron companion flanges include:

-

Tyler Union (Mueller): Comprehensive C110/A21.10 lineup, 2″–64″, asphaltic coatings.

-

Midland Industries: Threaded and blind flanges in Class 150, NS sizes up to 12″, black paint finish.

-

Winsupply: Regional distributor stocking flanged fittings and companion flanges.

-

BMI Canada: Excel price lists for U.S market; deep inventory of 4-bolt, 8-bolt patterns.

Six Commonly Asked Questions (FAQs)

1. What is the difference between a companion flange and a welded flange?

A companion flange (also called backing flange) is a loose flange that slides over the pipe end and bolts to another flange (e.g., lap-joint flange) or hub. It is not welded or integrally cast with the pipe, which allows it to rotate freely around the pipe. This rotational freedom is particularly valuable during installation and alignment of bolt holes, as it prevents the need to rotate the entire pipe assembly. Companion flanges are typically used with plain-end or lap-joint fittings and are rated for water and low-pressure steam services under ANSI/AWWA C110/A21.10 and ASME B16.1 Class 125 standards.

By contrast, a welded flange (e.g., weld neck flange per ASME B16.5) is permanently joined to the pipe via butt-welding, socket-welding, or threaded connection at the factory or job site. Welded flanges provide a strong, leak-tight joint capable of higher pressures and temperatures, making them suitable for process industries (oil & gas, chemical) where pressures exceed 300 psi or where high-temperature steam services are encountered. However, welded flanges require skilled welders and post-weld heat treatment or inspection, adding to installation cost and complexity.

In summary, companion flanges offer ease of assembly and alignment for low-pressure water systems, whereas welded flanges provide superior strength and integrity for high-pressure, high-temperature applications.

2. How do I select the correct gasket for a ductile iron companion flange?

Proper gasket selection is critical to ensure a leak-free seal between the raised faces of companion flanges. Key considerations:

-

Temperature and Pressure Rating

– For Class 125 (150 psi) potable water service: EPDM or nitrile (Buna-N) gaskets rated to 212 °F and 150 psi are commonly used.

– For hot water or steam (up to 300 °F): Non-asbestos compressed fiber gaskets rated to 300 °F and 150–200 psi. -

Gasket Type

– Full-face gaskets cover the entire flange face, providing added corrosion protection but require careful alignment.

– Ring-type joint (RTJ) gaskets are steel‐reinforced and fit into a groove for high-pressure service (rare for companion flanges). -

Material Compatibility

– EPDM resists ozone, UV, and most potable water chemicals.

– Nitrile is suitable for oils and fuels but limited for hot water. -

Thickness and Diameter

– Standard thickness is 1/8″ for most services.

– Inner and outer diameters must match the raised face OD and bolt circle to prevent extrusion under pressure.

3. Can companion flanges be used in buried piping systems?

Yes, companion flanges are routinely used in buried ductile iron water mains, especially in mechanical joint configurations. To ensure long-term performance underground:

-

Coating: External asphaltic or epoxy primer to SSPC standards.

-

Cathodic Protection: Sacrificial anodes or impressed-current systems to prevent soil-side corrosion.

-

Joint Restraint: Mechanical joint restraint devices (e.g., Megalug, Field Lok™) may be required in thrust areas to prevent flange separation under pressure surges.

Periodic inspection via test ports or valve stations can verify joint integrity without excavation.

4. What factors affect the delivery time and lead time for custom companion flanges?

Lead times depend on:

-

Size and Pressure Class: Large diameters (≥24″) and Class 250 flanges often require specialty tooling and longer casting cycles (6–12 weeks).

-

Coating Requirements: Epoxy liners or special external coatings add curing time (1–2 weeks).

-

Order Quantity: Small custom runs (<10 pieces) may incur mold setup delays; bulk orders benefit from existing inventory.

Planning for emergency repairs, many suppliers maintain stock of NPS 2″–12″ Class 125 companion flanges for same-day or next-day shipping.

5. How do ductile iron companion flange prices compare to steel flanges?

While ductile iron flanges generally cost 10–20% less than equivalent steel flanges (e.g., carbon steel weld-neck or slip-on per ASME B16.5), the total installed cost must consider:

-

Installation Time: Companion flanges bolt on quickly, avoiding hot-work permits and welding labor.

-

Field Alignment: Rotational freedom reduces downtime for bolt alignment.

-

Corrosion Liner: Cement mortar lining is standard on ductile iron, whereas steel flanges often need separate lining or internal coatings.

Typical street price for a 4″ Class 150 black ductile iron companion flange is around $70, versus $95–120 for a steel weld-neck flange.

6. Are reducing companion flanges available for mismatched pipe sizes?

Yes, reducing companion flanges allow direct connection between pipes of different nominal sizes without additional reducing bushings. For example, a 5″ × 11″ reducing companion flange features a 5″ hub for pipe insertion and an 11″ OD flange face, matching the bolt pattern of an 11″ mating flange. Reducing flanges are cast and machined per the same drilling templates as standard flanges, ensuring pressure rating consistency.