After installing countless cast iron pipes, I can confirm their weight varies dramatically by size and wall thickness. A standard 10-foot length of 4-inch diameter cast iron pipe weighs around 40 lbs (18 kg), while a 6-inch diameter pipe of the same length tips the scales at nearly 70 lbs (32 kg).

1. What Is Cast Iron Pipe?

Cast‑iron pipe is a hollow, strong iron alloy with 2–4 % carbon and other elements. It’s been used for centuries in water and wastewater systems, valued for rigidity and longevity.

There are two main types:

-

Grey cast iron (brittle, machinable)

-

Ductile iron (nodular graphite, more flexible, higher strength).

In engineering contexts, “cast iron pipe” typically refers to grey iron for soil/drainage and ductile for mains. In my career, I’ve seen both, but the weight questions often come down to grey cast‑iron soil pipe.

2. Materials, Standards & Nomenclature

2.1 Material Composition:

Grey cast iron: ~3.4 % C, 1.8 % Si, ~0.5 % Mn. Ductile iron: similar but with magnesium and spheroidal graphite.

2.2 Pipe Size Standards:

-

Nominal Pipe Size (NPS) in North America aligns roughly with internal diameter.

-

BS 78 (UK, 1917) classified cast‑iron water pipe by Classes A‑D with set OD/ID dimensions.

-

ASTM & CISPI standards govern soil pipe: ASTM A–888, CISPI 301 for hubless (no‑hub) cast‑iron soil pipe.

-

EN 877 covers cast‑iron fittings for drainage in buildings.

These standards impact wall thickness and OD, which directly affect weight.

3. How Heavy Is Cast Iron Pipe?

3.1 Weight Data: Standard & Extra‑Heavy Soil Pipe

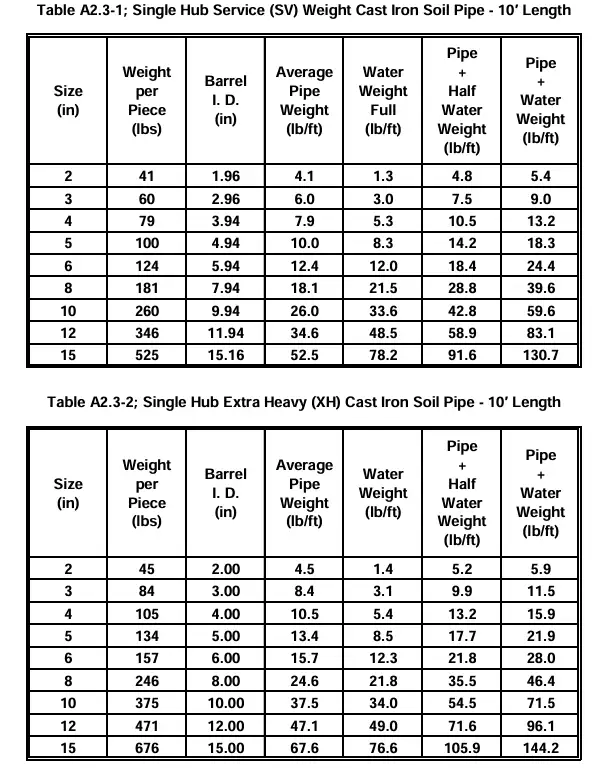

Here are typical weights per foot for ten‑foot grey cast‑iron soil pipe, as per Kinetics & Empire tables:

| Nom. Size (in) | Std‑Weight (lb/ft) | Std‑Weight⁺Water | X‑Heavy (lb/ft) | X‑Heavy⁺Water |

|---|---|---|---|---|

| 2″ | 4.1 | ~5.4 | 4.5 | ~5.9 |

| 3″ | 6.0 | ~9.0 | 8.4 | ~11.5 |

| 4″ | 7.9 | ~13.2 | 10.5 | ~15.9 |

| 6″ | 12.4 | ~24.4 | 15.7 | ~28.0 |

| 8″ | 18.1 | ~39.6 | 24.6 | ~46.4 |

| 10″ | 26.0 | ~59.6 | 37.5 | ~71.5 |

| 12″ | 34.6 | ~83.1 | 47.1 | ~96.1 |

| 15″ | 52.5 | ~130.7 | 67.6 | ~144.2 |

Water weight added for context.

3.2 Hubless (No‑Hub) vs. Single/Double Hub

Hubless soil pipe is lighter due to thinner hubs, but weight per foot is similar barrel‑wise. Ten‑foot bundles (e.g. 6″ x10′ = ~118 lbs per pipe) are commonly used .

3.3 Factors Affecting Weight

-

Pipe length (standard 10′ sections; 5′ exist too)

-

Wall class/pressure rating (std vs. extra‑heavy)

-

Material type (grey vs. ductile)

-

Coatings and linings (cement, asphalt) add small mass

In short: heavier classes = more material = more weight.

4. Comparison with Other Pipe Materials

Here’s how grey cast‑iron stands against alternatives:

| Material | �� lb/ft (6″ pipe) | Notes |

|---|---|---|

| Grey Cast‑Iron | ~12.4–15.7 | Durable, heavy |

| Ductile Iron | ~16–21 (approx.) | Similar dimensions, stronger |

| PVC | ~2–3 | Lightweight, flexible |

| HDPE | ~1.6–2.5 | Lightweight, corrosion‑resistant |

| Steel (SCH 40) | ~8–10 | Medium weight, weldable |

Cast‑iron is heavy, but medieval in robustness—remains in specs for decades.

5. Handling, Transport & Safety

I always say: “Don’t under‑estimate it—cast‑iron is deceptively heavy.”

Risks:

-

Manual lifting may exceed safe load limits → use proper team or mechanical means

-

Bundles can exceed 2,000 lb for 10 pipes → forklift recommended

-

On‑site storage: pipes must be racked to prevent rolling

Mitigation:

-

OSHA/ANSI‑compliant pipe‑cradles/slings

-

Gaskets protect edges when moving

-

PPE: gloves, steel‑toe boots, hardhats

It’s common jargon: “chunk of iron”—but truly, safe handling matters.

6. ISO & EN Standards (Europe & Beyond)

Outside North America, European standards apply:

-

ISO 2531 / EN 545 / EN 598 specify ductile/cast‑iron mains for water/sewer by DN size, wall class (e.g., K9, K10).

Example: DN150 (≈6″) under Class K9, wall = 5 mm, OD = 170 mm (~6.7″). Weight ~49 lb/ft according to manufacturer data .

7. Case Study: Municipal Trench Project

Context: City X replaces 600 LF of 8″ extra‑heavy cast‑iron on Main St.

Challenges:

-

10‑foot sections weigh ~24.6 lb/ft → ~246 lb per piece

-

Bundled weight ~1,968 lb (8 pieces/bundle)

Plan:

-

Crane offsite to jobsite

-

Rigged slings, PVC cushion

-

Bespoke trench bents to cradle pipes

-

Safety watchers observe pinch‑points

Result: Zero incidents over 2‑week install.

Lesson: Planning overcomes brute weight.

8. Key Takeaways

-

Cast‑iron pipes weigh 4–70 lb/ft depending on size/class.

-

Water weight matters—fully loaded pipes may double the total.

-

Standards (ASTM, CISPI, ISO) define dimensions/weight.

-

Safety planning is crucial—these are bricks on a stick.

-

It compares unfavorably in weight to plastic, but wins in durability, sound attenuation, life‑cycle.

🔍 FAQs

Q1: How much does a 4″ cast‑iron pipe weigh?

A: Standard 10′ length = ~79 lb, or 7.9 lb/ft. Extra‑heavy (XH) = ~105 lb, or 10.5 lb/ft.

Q2: Does filled cast‑iron pipe weigh significantly more?

A: Yes. Example: 4″ std pipe barrel = 7.9 lb/ft, water adds ~5.3 lb/ft → total ~13.2 lb/ft. For extra‑heavy, up to ~15.9 lb/ft .

Q3: Are there lighter alternatives?

A: PVC, HDPE, and steel options weigh far less—typically 1–3 lb/ft for plastics, 8–10 lb/ft for steel. But cast‑iron has unmatched robustness and sound damping.

Q4: What are the handling guidelines for cast‑iron pipe?

A: Use mechanised lifting above ~150 lb, cradle support, gaskets, PPE, team‑lift if manual. OSHA and ANSI standards apply.

Q5: How do European standards affect weight?

A: ISO/EN specify wall thicknesses per DN/class (e.g., DN150–5 mm wall). Manufacturer data (e.g., Class K9) indicate ~49 lb/ft for 6″ nominal pipe .