Carbidic Austempered Ductile Iron (CADI) represents a groundbreaking advancement in materials engineering, combining the ductility of nodular graphite iron with the wear resistance of carbides and the toughness of ausferritic microstructures. Through precise heat treatment and alloy design, CADI achieves unparalleled mechanical properties, including exceptional hardness (500-700 HV), high fatigue strength, and superior abrasion resistance. This material outperforms conventional ductile iron, high-carbon steels, and even some ceramic composites in heavy-duty industrial applications such as mining equipment, rail components, and agricultural machinery. With a unique microstructure comprising ausferrite (acicular ferrite + stabilized austenite) and dispersed carbides, CADI reduces lifecycle costs by 30-50% in wear-intensive environments while maintaining machinability and impact resistance.

1. Metallurgical Fundamentals of CADI

Carbidic Austempered Ductile Iron derives its properties from a meticulously controlled three-stage heat treatment process:

-

Austenitization: Heating to 850-950°C to dissolve carbon into austenite

-

Quenching: Rapid cooling to 250-400°C in salt baths or oil

-

Isothermal Holding: Maintaining temperature for 1-4 hours to form ausferrite

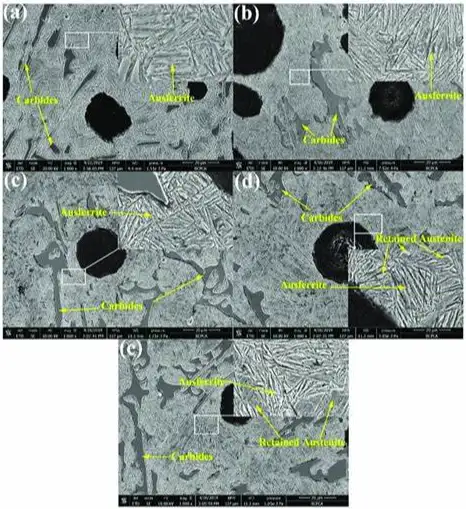

The microstructure comprises:

-

Nodular Graphite (10-15% volume): Ensures stress distribution and crack inhibition

-

Ausferrite Matrix: Combines high-strength acicular ferrite (70-85%) with carbon-rich retained austenite (15-30%)

-

Carbide Networks (5-10%): Chromium or vanadium carbides provide wear resistance

Table 1: Phase Composition Comparison

| Component | CADI (%) | ADI (%) | Ductile Iron (%) |

|---|---|---|---|

| Graphite | 12 | 10 | 10-15 |

| Austenite | 25 | 30 | 0 |

| Ferrite | 58 | 60 | 85-95 |

| Carbides | 5 | 0 | 0 |

Key alloying elements include:

-

Nickel (1-2%): Stabilizes austenite

-

Molybdenum (0.3-0.6%): Inhibits pearlite formation

-

Chromium (0.5-1.5%): Forms hard carbides

2. Manufacturing Process Optimization

The production of CADI requires strict control across six critical stages:

Stage 1: Melting & Nodularization

-

Base iron composition: 3.4-3.8% C, 2.2-2.8% Si

-

Magnesium treatment (0.04-0.06% residual Mg) for nodular graphite formation

Stage 2: Carbide Precipitation

-

Controlled cooling rates (10-20°C/min) to precipitate M7C3/M23C6 carbides

-

Carbide size optimization: 2-8 μm for balanced wear and toughness

Stage 3: Austempering Parameters

| Parameter | Optimal Range | Effect on Properties |

|---|---|---|

| Austenitizing Temp | 900±10°C | Controls carbon solubility |

| Quench Medium | Nitrate salts | Minimizes distortion |

| Holding Time | 2-3 hours | Determines austenite carbon % |

Industrial trials demonstrate that a 320°C austempering temperature yields optimal hardness (580 HV) and impact energy (80 J).

3. Performance Comparison with Competing Materials

Table 2: Mechanical Properties Benchmark

| Property | CADI | ADI | High-Cr Steel | Ceramic |

|---|---|---|---|---|

| Hardness (HV) | 550-700 | 300-450 | 600-800 | 1200-1500 |

| Tensile Strength | 1200 MPa | 1000 MPa | 900 MPa | 300 MPa |

| Wear Rate (mm³/m) | 0.15 | 0.35 | 0.25 | 0.08 |

| Impact Energy | 75 J | 100 J | 25 J | 2 J |

CADI outperforms ADI in wear resistance by 57% while maintaining 75% of its impact toughness. Compared to high-chromium steels, it offers better machinability (tool life improvement: 3-5×) and lower density (7.1 vs 7.8 g/cm³).

4. Industrial Applications & Case Studies

Mining Sector:

-

Crusher liners: CADI components last 2.3× longer than manganese steel in copper ore processing

-

Grinding balls: 40% reduction in media consumption at Chilean copper mines

Railway Systems:

-

Brake discs: 800,000 km service life vs 500,000 km for conventional cast iron

-

Frogs and crossings: 12-year maintenance interval vs 8 years for forged steel

Agricultural Machinery:

-

Plowshares: 60% wear reduction in abrasive soils

-

Combine harvester blades: 2.5× lifespan improvement

5. Economic & Sustainability Impact

-

Lifecycle Cost Reduction: CADI components lower replacement frequency by 30-60%

-

CO2 Footprint: 22% lower emissions per ton compared to steel due to reduced material waste

-

Recyclability: 95% of CADI scrap can be reused in foundry processes

6. Future Research Directions

-

Nano-Carbide Reinforcement: Incorporating 50-100 nm TiC particles to boost hardness

-

AI-Driven Heat Treatment: Machine learning models for real-time austempering control

-

Hybrid Composites: CADI matrix with embedded carbon fiber layers for aerospace

Frequently Asked Questions (FAQs)

Q1: Why choose CADI over traditional quenched & tempered steels?

CADI provides superior wear resistance (2-3× improvement) while maintaining ductility due to its unique ausferrite-carbide microstructure. Unlike brittle hardened steels, CADI components withstand impact loads up to 100 J without cracking, making them ideal for mining crushers and earth-moving equipment. The absence of martensitic transformation stresses allows for better dimensional stability in complex geometries.

Q2: How does austempering temperature affect CADI properties?

Lower austempering temperatures (250-300°C) produce higher hardness (650-700 HV) through finer ausferrite needles, ideal for abrasive wear applications. Higher temperatures (350-400°C) increase retained austenite content (25-30%), enhancing impact toughness for components subjected to dynamic loads. Industry standards recommend 320±10°C for balanced performance.

Q3: Can CADI replace cemented carbides in cutting tools?

While CADI’s hardness (max 700 HV) remains below WC-Co carbides (1500-2000 HV), it offers better fracture toughness (15 MPa√m vs 8-12 MPa√m) at 20% of the cost. Recent trials show CADI inserts perform comparably to carbide tools in non-ferrous machining at feed rates below 0.3 mm/rev.

Q4: What limits CADI’s maximum service temperature?

The ausferrite structure remains stable up to 400°C. Beyond this, retained austenite decomposes into brittle ferrite-carbide aggregates. For high-temperature applications (>450°C), silicon-molybdenum alloy variants with stabilized carbides can extend the limit to 550°C.

Q5: How does CADI compare to bainitic steels in gear applications?

CADI gears exhibit 30% higher pitting resistance (ISO 6336-2) due to strain-induced austenite transformation. However, high-precision gears (<IT7 tolerance) still require steel for better machined surface finish. Hybrid designs using CADI gear bodies with steel tooth coatings are gaining traction.

Q6: What are the machining challenges with CADI?

The carbide network increases tool wear rates by 40% compared to ADI. Recommended practices:

-

Use PCBN tools for finishing (Vc=150-180 m/min, feed=0.1 mm/rev)

-

Employ high-pressure coolant (≥70 bar) to prevent notch wear

-

Avoid interrupted cuts; carbide pull-out can cause surface defects

References:

1. Austempered Ductile Iron (ADI) – Heat Treatment and Microstructure

2. ISO 1083:2018 – Spheroidal Graphite Cast Iron (Ductile Iron) Grades

3. Carbidic Austempered Ductile Iron: Emerging Material for Wear Applications

4. ISO 6336-2:2019 – Calculation of Load Capacity of Spur and Helical Gears (Pitting Resistance)