Carbide formation in ductile iron is a critical aspect that influences the material’s mechanical properties, including strength, hardness, and ductility. Understanding the mechanisms behind carbide formation, the factors that promote or inhibit it, and the strategies to control it is essential for producing high-quality ductile iron components. This article provides a comprehensive analysis of carbide formation in ductile iron, covering its causes, effects, and mitigation techniques to optimize performance in various applications.

1. Mechanisms of Carbide Formation in Ductile Iron

Carbides in ductile iron primarily form during the solidification process when certain conditions favor the precipitation of iron carbides over graphite. The presence of carbide-forming elements, cooling rates, and the composition of the melt play significant roles in this process.

1.1. Solidification Process

During solidification, the competition between graphite and carbide formation is influenced by the chemical composition and cooling rate. Rapid cooling or the presence of carbide-stabilizing elements can suppress graphite formation, leading to carbide precipitation.

1.2. Types of Carbides

Carbides in ductile iron can be classified into primary (eutectic) carbides and secondary carbides. Primary carbides form during the initial solidification, while secondary carbides precipitate during subsequent cooling or heat treatment processes.

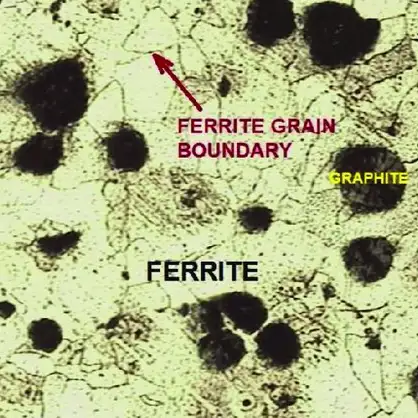

1.3. Microstructural Characteristics

The morphology and distribution of carbides affect the mechanical properties of ductile iron. Carbides can appear as network structures, isolated particles, or along grain boundaries, each influencing the material’s behavior under stress differently.

2. Influencing Factors on Carbide Formation

Several factors influence the formation of carbides in ductile iron, including chemical composition, cooling rate, and inoculation practices.

2.1. Chemical Composition

Elements such as chromium, molybdenum, vanadium, and manganese are known to promote carbide formation. Their presence in the melt can stabilize carbides, especially when present in higher concentrations.

2.2. Cooling Rate

Faster cooling rates can suppress graphite formation, favoring carbide precipitation. Controlling the cooling rate during solidification is crucial to manage carbide content.

2.3. Inoculation Practices

Proper inoculation with elements like silicon, calcium, and aluminum can promote graphite nucleation, reducing the tendency for carbide formation. Inadequate inoculation can lead to increased carbide content.

3. Effects of Carbides on Mechanical Properties

The presence of carbides in ductile iron significantly impacts its mechanical properties, including strength, hardness, ductility, and machinability.

3.1. Strength and Hardness

Carbides increase the hardness and strength of ductile iron, making it suitable for wear-resistant applications. However, excessive carbide content can lead to brittleness.

3.2. Ductility

High carbide content reduces ductility, making the material more prone to cracking under stress. Balancing carbide content is essential to maintain adequate ductility.

3.3. Machinability

Carbides are hard phases that can cause increased tool wear during machining, reducing machinability. Controlling carbide content is vital for manufacturing processes requiring extensive machining.

4. Control Strategies for Carbide Formation

Implementing effective control strategies during the production of ductile iron can minimize undesirable carbide formation.

4.1. Composition Control

Adjusting the levels of carbide-forming elements and maintaining optimal carbon and silicon content can reduce carbide formation.

4.2. Cooling Rate Management

Controlling the cooling rate during solidification through mold design and casting parameters helps manage carbide precipitation.

4.3. Inoculation Techniques

Employing appropriate inoculation practices with suitable inoculants enhances graphite nucleation, suppressing carbide formation.

5. Comparative Analysis: Carbide Formation in Different Ductile Iron Grades

| Ductile Iron Grade | Carbide Content | Mechanical Properties | Applications |

|---|---|---|---|

| Ferritic | Low | High ductility, low strength | Pressure pipes, automotive components |

| Pearlitic | Moderate | Balanced strength and ductility | Gears, crankshafts |

| Carbidic | High | High hardness, low ductility | Wear-resistant parts |

Understanding the carbide content in different ductile iron grades aids in selecting the appropriate material for specific applications.

6. Frequently Asked Questions (FAQs)

Q1: What causes carbide formation in ductile iron?

A1: Carbide formation in ductile iron is primarily caused by the presence of carbide-stabilizing elements (e.g., chromium, molybdenum, vanadium) and rapid cooling rates during solidification. These factors suppress graphite formation, leading to carbide precipitation.

Q2: How does carbide content affect the mechanical properties of ductile iron?

A2: Increased carbide content enhances hardness and wear resistance but reduces ductility and machinability. Excessive carbides can make the material brittle and challenging to machine.

Q3: Can carbide formation be controlled during ductile iron production?

A3: Yes, controlling chemical composition, cooling rates, and employing proper inoculation techniques can effectively manage carbide formation in ductile iron.

Q4: What are the benefits of carbidic ductile iron?

A4: Carbidic ductile iron offers high hardness and wear resistance, making it suitable for applications requiring durability, such as wear-resistant parts and heavy-duty machinery components.

Q5: How does inoculation influence carbide formation?

A5: Inoculation introduces elements that promote graphite nucleation, reducing the tendency for carbide formation. Proper inoculation is crucial for achieving the desired microstructure in ductile iron.

Q6: What is the role of silicon in carbide formation in ductile iron?

A6: Silicon acts as a graphitizing agent, promoting graphite formation and suppressing carbide precipitation. Maintaining optimal silicon levels is essential for controlling carbide content in ductile iron.

References:

1. ASTM A536 – Standard Specification for Ductile Iron Castings

2. Ductile Iron Society – Metallurgy of Ductile Iron

3. European Standard EN 1563 – Founding – Spheroidal Graphite Cast Irons