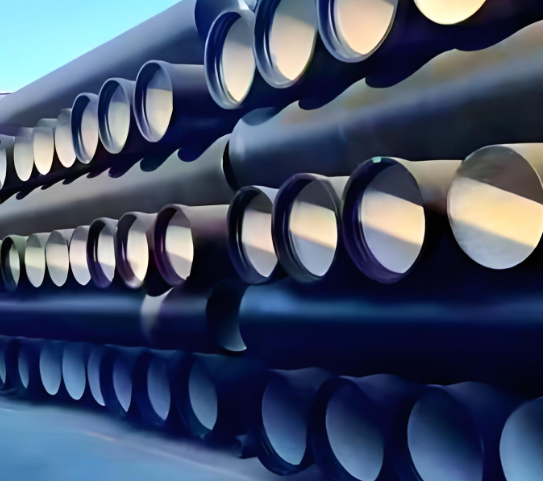

Yes, ductile iron pipes can be cut with a snap cutter, which is a common tool used in the plumbing and piping industry. Snap cutters are designed to quickly and efficiently cut through ductile iron, especially in tight spaces where other cutting tools might not fit. The process involves using a set of hardened steel blades that apply pressure to the pipe, causing it to break cleanly along the cut line. While snap cutters are effective for making precise cuts, it’s important to ensure the tool is in good condition and suitable for the specific pipe diameter to avoid damaging the pipe. Additionally, workers should wear protective gear during the cutting process to ensure safety.

Why Snap Cutters Struggle with Ductile Iron Pipes

Snap cutters (aka ratchet cutters) work by scoring and breaking pipes, making them ideal for brittle materials. However, ductile iron’s nodular graphite structure gives it flexibility and strength, which resists the snap-and-break method:

-

Material Toughness: Ductile iron bends rather than cracks under pressure.

-

Risk of Tool Damage: Forcing a snap cutter can blunt blades or warp the tool.

-

Uneven Cuts: Incomplete breaks may leave jagged edges, compromising pipe integrity.

How to Cut Ductile Iron Pipe Safely: 3 Reliable Methods

1. Angle Grinder with Abrasive Disc

-

Best for: Quick, straight cuts on-site.

-

Steps:

-

Mark the cutting line with chalk.

-

Use a diamond or carbide-tipped cutting disc (1/8-inch thickness).

-

Cut at a 90° angle, applying steady pressure.

-

Smooth edges with a grinding disc.

-

-

Safety: Wear goggles, gloves, and a respirator to avoid metal dust.

2. Plasma Cutter

-

Best for: Thick pipes or high-volume projects.

-

Steps:

-

Secure the pipe in a vise.

-

Set the plasma cutter to 40–50 amps for 6-inch pipes.

-

Follow the marked line steadily.

-

-

Pros: Fast, precise, minimal cleanup.

3. Portable Band Saw

-

Best for: Controlled, clean cuts in workshops.

-

Tips:

-

Use bi-metal blades with 18–24 TPI (teeth per inch).

-

Apply cutting fluid to reduce heat and blade wear.

-

Snap Cutter Alternatives: Quick Comparison

| Tool | Speed | Cut Quality | Portability | Cost |

|---|---|---|---|---|

| Angle Grinder | Fast | Moderate | High | $ |

| Plasma Cutter | Very Fast | High | Moderate | $$$ |

| Band Saw | Slow | High | Low | $$ |

| Oxy-Acetylene Torch | Moderate | Low | High | $$ |

Why Avoid Snap Cutters for Ductile Iron?

- Wasted Time: Repeated attempts rarely yield clean breaks.

- Safety Hazards: Slipping tools or flying debris risk injury.

- Pipe Damage: Jagged edges can leak or weaken joints.

Pro Tip: If you must use a snap cutter, pre-score the pipe with an angle grinder to guide the break.

FAQs About Cutting Ductile Iron Pipes

Q: Can I use a hacksaw for small ductile iron pipes?

A: Yes, but only for pipes under 2 inches. Use a high-tensile blade and expect slow progress.

Q: Do I need to anneal ductile iron before cutting?

A: No—annealing softens metal, but ductile iron retains strength even when cut cold.

Q: How do I prevent burrs on cut edges?

A: Grind edges with a flapper disc or file, then deburr with sandpaper.

Key Takeaways

- Snap cutters are not ideal for ductile iron—opt for angle grinders, plasma cutters, or band saws.

- Prioritize blade quality and safety gear to avoid accidents.

- For large projects, renting industrial tools saves time and effort.

By choosing the right method, you’ll achieve precise, safe cuts on ductile iron pipes while extending tool life and project efficiency.

References:

- Ductile Iron Pipe – Wikipedia

- Metal Cutting Safety – Occupational Safety and Health Administration (OSHA)

- ASTM A536 – Standard Specification for Ductile Iron Castings – ASTM International

- NFPA 70E: Standard for Electrical Safety in the Workplace – National Fire Protection Association

- Hand and Power Tools Safety – Occupational Safety and Health Administration (OSHA)