The “C Factor” is a critical parameter in the context of ductile iron pipes used in fluid transport, primarily in water systems. It represents the pipe’s hydraulic efficiency and is an essential aspect in determining flow characteristics, pressure loss, and the longevity of the pipe in service. This article will delve into the definition of the C Factor, its significance, calculation methods, variations for different pipe materials, and how it affects the overall performance of ductile iron piping systems.

1. What is the C Factor?

The C Factor is a numerical value used to quantify the roughness of a pipe’s interior surface. In simple terms, it represents the ease with which water or other fluids can flow through a pipe. The higher the C Factor, the smoother the pipe’s interior, which allows for more efficient fluid flow and less resistance.

-

C Factor Definition: The C Factor, often referred to as the Hazen-Williams C Factor when applied to water flow, can vary based on several factors such as pipe material, age, and internal corrosion.

-

Importance in Pipe Design: A higher C Factor implies lower friction losses, which leads to more efficient fluid flow and reduced pumping costs.

2. Factors That Influence the C Factor of Ductile Iron Pipes

Several factors determine the C Factor for ductile iron pipes, including:

-

Manufacturing Process: Modern ductile iron pipes have a smoother internal surface compared to older versions.

-

Corrosion and Wear: Over time, corrosion and biofilm buildup can lower the C Factor, which results in higher friction losses.

-

Internal Lining: The type of coating and internal lining (e.g., cement mortar lining) can have a significant impact on the pipe’s roughness and, consequently, its C Factor.

3. Calculating the C Factor for Ductile Iron Pipe

-

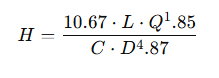

Formula: The C Factor is often used in the Hazen-Williams equation to determine pressure drop and flow in pipes:

Calculating the C Factor for Ductile Iron Pipe Where:

-

H = head loss (ft)

-

L = length of the pipe (ft)

-

Q = flow rate (gpm)

-

C = Hazen-Williams C Factor

-

D = diameter of the pipe (inches)

-

-

Typical Values for Ductile Iron Pipes: A typical C Factor for new ductile iron pipes can range from 130 to 140. However, older pipes or those with significant wear may see a reduction in the C Factor.

4. The Effect of C Factor on Pipe Sizing and Design

-

Pipe Sizing: A higher C Factor can reduce the required pipe diameter for a given flow rate and pressure loss, helping engineers optimize design.

-

Impact on Energy Costs: A higher C Factor reduces friction loss, leading to lower energy consumption for pumping.

5. C Factor Variations for Different Ductile Iron Pipe Coatings

-

Uncoated vs. Coated Pipes: Ductile iron pipes with cement mortar linings or epoxy coatings typically exhibit a higher C Factor due to their smoother internal surfaces.

-

Effects of Aging: Older pipes without protective coatings may experience a reduction in C Factor due to corrosion and scale buildup, leading to higher frictional resistance and energy costs.

6. C Factor in Comparison with Other Materials

To better understand the performance of ductile iron pipes, it’s important to compare their C Factor with other common materials like PVC and steel. The table below provides a comparison of C Factors for different materials:

| Pipe Material | C Factor Range |

|---|---|

| Ductile Iron (new) | 130 – 140 |

| Ductile Iron (old) | 100 – 120 |

| PVC | 150 – 160 |

| Steel | 100 – 120 |

| Concrete | 100 – 110 |

7. Impact of C Factor on Flow Calculations

The C Factor plays a crucial role in determining the capacity of a pipe to transport fluids. By using the C Factor in flow calculations, engineers can design systems that minimize pressure loss and ensure optimal flow.

8. C Factor and Pipe Longevity

-

Long-term Performance: Ductile iron pipes generally maintain a high C Factor for longer periods than other materials, assuming proper maintenance and installation.

-

Maintenance Implications: Regular inspections and cleaning can help maintain the pipe’s C Factor, ensuring long-term efficiency and cost savings.

9. Key Considerations for Engineers

When designing a pipeline system, engineers must consider:

-

Choosing the Right Pipe Material: Ductile iron pipes may offer a longer lifespan compared to some alternatives.

-

Predicting Long-Term Performance: It is vital to account for potential decreases in C Factor due to wear and aging.

-

Optimizing Pumping Costs: The C Factor affects the energy costs, and selecting pipes with high C Factor values can reduce operational expenses over time.

FAQs

1. How does the C Factor affect the water flow rate in ductile iron pipes?

The C Factor directly influences the resistance to water flow in a pipe. A higher C Factor indicates smoother pipe walls, resulting in lower friction and higher flow rates. Conversely, a lower C Factor increases friction, reducing flow efficiency.

2. What are the common C Factor values for ductile iron pipes?

New ductile iron pipes typically have a C Factor between 130 and 140. As the pipes age, corrosion and buildup of debris can reduce the C Factor, which may drop to 100 or lower in older pipes.

3. Can the C Factor be improved over time?

Yes, proper maintenance such as cleaning and the application of internal coatings can help improve or maintain the C Factor of ductile iron pipes. Additionally, the use of linings such as cement mortar or epoxy coatings can reduce internal roughness.

4. What happens if the C Factor is too low?

A low C Factor means higher friction losses in the system, which results in increased energy consumption, higher pumping costs, and potentially reduced flow rates. This can lead to system inefficiency and higher operational costs.

5. How does the C Factor affect the selection of ductile iron pipe size?

A higher C Factor allows for smaller pipe diameters to achieve the same flow rates and pressure drops. This can help reduce material costs and space requirements in a pipeline design.

6. Is the C Factor the same for all ductile iron pipes?

No, the C Factor can vary depending on the pipe’s age, coating, and internal condition. New ductile iron pipes tend to have a higher C Factor than older or uncoated pipes due to smoother internal surfaces.