Ductile iron pipes are widely used in water distribution systems, sewage systems, and many industrial applications due to their durability, strength, and versatility. However, when installing these pipes, proper sealing and connection methods are crucial for their long-term functionality. One important component in this process is the brass wedge. Brass wedges play an essential role in securing the joints of ductile iron pipes, ensuring a tight, leak-free seal.

In this comprehensive guide, we will cover everything you need to know about brass wedges for ductile iron pipes, including their types, sizes, prices, and why they are vital for pipe installations. The following sections will delve into the various aspects of brass wedges, their use in ductile iron pipe systems, and other relevant considerations for contractors, engineers, and procurement managers.

1. Introduction to Brass Wedges in Ductile Iron Pipe Systems

What Are Brass Wedges?

Brass wedges are small, wedge-shaped components typically used in the installation and connection of ductile iron pipes. These wedges are inserted into the grooves of the pipe joints to ensure a secure and leak-proof connection. Their primary role is to assist in the sealing process and prevent any movement or misalignment of the pipes once they are in place.

Why Are Brass Wedges Used?

Brass is selected for these wedges because it is resistant to corrosion, durable, and offers good mechanical properties, which are essential for maintaining a secure and long-lasting connection. Brass wedges are typically used in the push-on joints and mechanical joints of ductile iron pipe systems.

2. The Role of Brass Wedges in Ductile Iron Pipe Installation

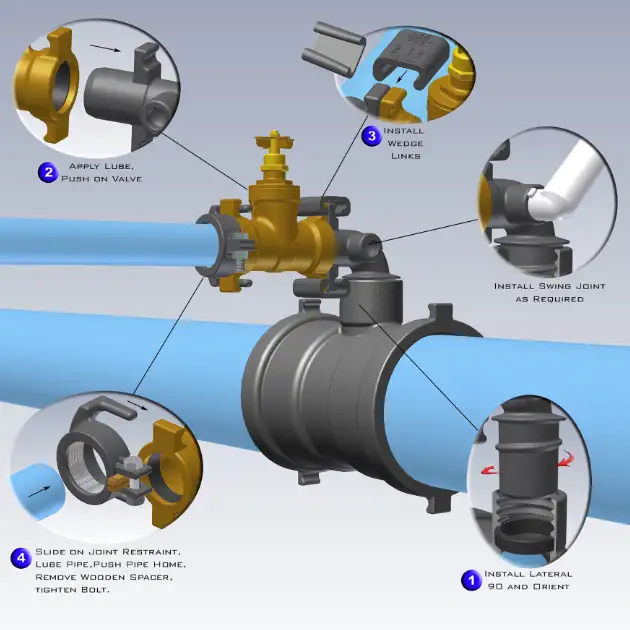

Brass wedges are particularly important when it comes to the installation of ductile iron pipes with push-on joints. These joints are designed to allow for a quick and easy connection between pipe sections. When a brass wedge is inserted, it ensures that the gasket in the pipe joint compresses properly, creating a tight seal to prevent leakage.

For mechanical joints, brass wedges also ensure that the joint is firmly locked in place, providing stability and strength to the entire pipeline system. This is especially important in high-pressure systems, where even minor leaks can lead to significant issues.

Applications of Brass Wedges in Different Systems:

-

Water Supply Systems: Brass wedges help create leak-proof connections in drinking water distribution systems.

-

Sewer and Stormwater Systems: These wedges provide a reliable and tight seal in wastewater pipelines.

-

Industrial Applications: Brass wedges are used in various industrial settings where ductile iron pipes are employed to transport chemicals, gases, or other materials.

3. Brass Wedge Sizes for Ductile Iron Pipes

Brass wedges are available in various sizes, which correspond to the diameter of the ductile iron pipes they are meant to secure. The size of the brass wedge is crucial because it must match the groove dimensions of the pipe joint to ensure proper compression of the gasket and a secure connection.

Standard Sizes of Brass Wedges

The most common sizes for brass wedges used in ductile iron pipes include:

| Pipe Size (inches) | Wedge Length (inches) | Wedge Width (inches) | Typical Applications |

|---|---|---|---|

| 4 | 3.25 | 1.25 | Small water supply systems |

| 6 | 4.25 | 1.50 | Residential and small commercial |

| 8 | 5.25 | 1.75 | Large water distribution networks |

| 12 | 7.50 | 2.00 | Large-scale industrial applications |

| 16 | 9.25 | 2.50 | Heavy-duty pipelines and high-pressure systems |

| 20 | 11.00 | 3.00 | Large infrastructure projects |

Brass wedges are typically designed to fit standard ductile iron pipe joint sizes. It’s crucial to match the wedge size to the pipe’s joint specifications to ensure proper fitment.

4. The Pricing of Brass Wedges for Ductile Iron Pipes

The price of brass wedges varies depending on the size, quality, and quantity purchased. Typically, the price will be influenced by the following factors:

-

Pipe Size: Larger pipes require larger wedges, which generally cost more.

-

Quantity: Bulk orders may lower the cost per unit.

-

Quality of Brass: Higher-grade brass with better corrosion resistance and strength may come at a premium price.

Average Price Range:

| Pipe Size (inches) | Price Range (USD per wedge) |

|---|---|

| 4 | $5 – $8 |

| 6 | $6 – $10 |

| 8 | $7 – $12 |

| 12 | $12 – $20 |

| 16 | $15 – $25 |

| 20 | $20 – $30 |

Additional Cost Factors:

-

Shipping and Handling: Large orders may incur higher shipping costs.

-

Customization: If customized brass wedges are required, the price may increase.

For most standard installations, brass wedges are relatively affordable, but they can still represent a significant portion of the overall installation cost, especially in large infrastructure projects.

5. Advantages of Using Brass Wedges in Ductile Iron Pipe Systems

Brass wedges offer several advantages in ductile iron pipe systems:

-

Corrosion Resistance: Brass is resistant to corrosion and does not degrade easily in contact with water, soil, or other environmental elements.

-

Strength and Durability: Brass wedges are highly durable and can withstand the pressures exerted in water and sewer systems.

-

Improved Sealing: By ensuring proper gasket compression, brass wedges improve the sealing ability of the joint, preventing leaks and potential failures.

-

Ease of Installation: Brass wedges are easy to install and remove, making them a practical choice for pipe joint assembly.

-

Cost-Effectiveness: Despite their durability, brass wedges are relatively inexpensive, offering a good balance between performance and cost.

6. Common Applications for Brass Wedges in Ductile Iron Pipe Systems

Brass wedges are commonly used in several key applications where ductile iron pipes are employed, including:

-

Municipal Water Systems: Brass wedges help form reliable and leak-resistant joints in water distribution networks.

-

Wastewater Treatment: In sewer systems, brass wedges secure pipe connections to ensure proper fluid transport without leaks.

-

Agricultural Irrigation: Brass wedges provide a cost-effective solution for irrigation systems that use ductile iron pipes.

-

Industrial Applications: In industries requiring the transport of liquids or gases, brass wedges ensure that high-pressure pipes remain sealed under extreme conditions.

7. Comparing Brass Wedges with Other Joint Types

Brass wedges are just one method of securing ductile iron pipe joints. Other options include rubber gaskets, flanged joints, and mechanical couplings. Below is a comparison of these options:

| Feature | Brass Wedge | Rubber Gasket | Flanged Joint | Mechanical Coupling |

|---|---|---|---|---|

| Durability | High | Moderate | Very High | High |

| Ease of Installation | Easy | Easy | Moderate | Easy |

| Cost | Low to Moderate | Low | High | Moderate |

| Leak Prevention | Excellent | Good | Excellent | Good |

| Corrosion Resistance | Excellent | Moderate | Very High | High |

| Maintenance | Low | Low | High | Moderate |

While brass wedges offer an excellent balance of cost and performance, other joint types may be more suitable for specific applications or environments.

8. Frequently Asked Questions (FAQs)

Q1: How do I determine the correct size of brass wedge for my ductile iron pipe?

To select the correct brass wedge size, you should refer to the pipe’s size and joint specifications. Brass wedges are typically sized to match the groove dimensions of the pipe, so check the manufacturer’s specifications or consult an expert if unsure.

Q2: Are brass wedges used in all ductile iron pipe systems?

While brass wedges are commonly used in push-on and mechanical joints, other types of connections may use different methods, such as rubber gaskets or flanged joints. The choice of connection depends on the system’s requirements and environmental conditions.

Q3: How long do brass wedges last in ductile iron pipe systems?

Brass wedges have a long lifespan due to their corrosion resistance and durability. They typically last for the lifetime of the pipe, provided that they are installed properly and the pipe is maintained.

Q4: Can brass wedges be used in high-pressure systems?

Yes, brass wedges are suitable for high-pressure applications because they help ensure a tight, leak-proof seal. However, the system’s design and the pipe’s specifications should always be considered when selecting the wedge material.

Q5: How do I install brass wedges in ductile iron pipes?

Brass wedges are typically installed during the pipe joint assembly process. The wedge is inserted into the groove of the pipe joint to compress the gasket and secure the joint in place. It’s important to follow the manufacturer’s instructions for proper installation.

Q6: Are there any alternatives to brass wedges?

Yes, alternatives include rubber gaskets, mechanical couplings, and flanged joints. The choice depends on the application, the environmental conditions, and cost considerations.