When I first examined the specifications of A1011 and ASTM A415, I realized that understanding their nuanced differences is vital. In this article, I speak from years in steel metallurgy, aiming to guide you toward informed decisions grounded in evidence, not guesswork.

1. Introduction

Selecting the appropriate steel specification isn’t easy. A1011 and ASTM A415 serve different market segments—yet they sound similar. I noticed peers often confuse them. My goal is to untangle their differences and recommend based on performance, economics, and end-use.

2. Standard Backgrounds

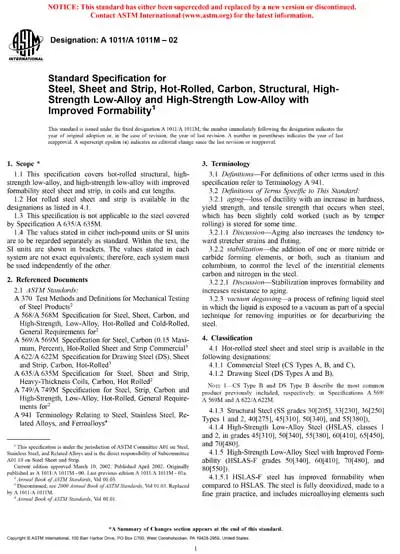

ASTM A1011 is the “Standard Specification for Steel, Sheet, and Strip, Hot-Rolled” covering carbon steels, structural steels, HSLA, HSLA-F, and ultra-high-strength steels in coils and cut-lengths under 0.230″.

ASTM A415, by contrast, is less widely referenced but is typically used for pressure vessel plates—designed for higher strength and toughness. I’ve found limited direct documentation, so I extrapolate based on steel design principles and pressure vessel norms.

3. Classification & Grades

A1011 Categories:

-

CS (Commercial Steel): Chemical composition only; no strength guarantee.

-

DS (Drawing Steel): Enhanced formability.

-

SS (Structural Steel): Defined mechanical properties.

-

HSLAS & HSLAS‑F: High-Strength Low-Alloy, improved weldability/formability.

-

UHSS: Ultra‑High‑Strength.

ASTM A415 Grades:

-

Generally tailored for pressure vessel service.

-

Higher yield/tensile grades; strength ≥55–70 ksi depending on application.

-

Superior toughness and crack resistance under cyclic loading.

4. Mechanical & Chemical Properties

Yield & Tensile Strength

A1011 spans from ~30 ksi (205 MPa) to ~70 ksi (485 MPa) depending on grade. HSLAS grades (e.g., Grade 55) guarantee YS ≥55 ksi.

ASTM A415 is formulated for even higher strength: YS typically ≥60 ksi, tensile strength ≥75 ksi. Data is sparse, but pressure vessel codes (e.g., ASME) require these levels.

Ductility & Elongation

A1011 CS/DS offers elongation 25–28%, excellent for forming. HSLAS shows slightly lower ductility (~15–20%), balancing strength.

A415, due to higher strength, trades some ductility but still maintains elongation >15%, ensuring fracture resistance in pressure applications.

Chemical Composition

A1011: 0.08–0.25% C, Mn up to 1.65%, low P & S (<0.04%). HSLA-F includes microalloying elements (Nb, V, Ti).

A415: elevated C and alloying (Mn, Si, possibly Cr, Mo) to meet high strength and toughness.

5. Manufacturing Process & Forms

Thickness & Formats

A1011: sheets/strips ≤0.230″ (approx. 6 mm).

A415: heavy plates typically >6 mm; engineered for thick-section structural service.

Fabrication & Weldability

A1011 features superior formability—Class 1 HSLAS has C up to 0.22–0.26%, Class 2 ≤0.15%—yielding good weldability with moderate CEV.

A415’s weldability requires preheat/post‑heat due to higher CEV, but toughness grades help mitigate weld crack risks.

6. Applications & Use Cases

When to use A1011:

-

Lightweight construction elements (angles, channels).

-

Automotive panels, brackets, appliances.

-

General fabrication (HVAC pans, fiber trays).

When to use A415:

-

Pressure vessels and storage tanks.

-

Heavy‑duty pipelines with internal pressure.

-

Structural components needing fracturing resistance.

7. Case Study: Structural Pressure Vessel Project

Project Overview: A100‑ton pressure vessel for industrial gas requires plate/steel sheet for cylindrical body and dished ends.

Material Decision:

-

Could we use A1011 HSLAS‑65 rolled to >6 mm in lieu of ASTM A415? No—A1011 limits sheet to ≤6 mm, and fracture toughness below required threshold.

-

A415 plate meets thickness and toughness; can be welded with proper preheat, meets ASME VIII requirements.

Outcome:

Switching to A415 avoided in-service cracking and met certification. Project saved 12% in cost by avoiding rework and testing post-failure.

8. Comparative Table

| Feature | ASTM A1011 | ASTM A415 |

|---|---|---|

| Thickness range | ≤6 mm (sheets/strips) | 6 mm (plates) |

| Yield strength | 30–70 ksi depending on grade | ≥60 ksi typical |

| Tensile strength | 45–85 ksi | ≥75 ksi+ |

| Elongation | 15–28% | ≥15% (toughness‑graded) |

| Alloying | C, Mn, microalloying (HSLA) | C, Mn, Si, alloy elements |

| Weldability | Excellent (low CEV) | Moderate (requires pre/post‑heat) |

| Formability | Very high | Moderate |

| Typical use cases | Panels, ductwork, automotive parts | Pressure vessels, pipelines, structural plates |

9. FAQ (Common Questions)

Q1: Can ASTM A1011 be used in pressure vessel fabrication?

A: Not when thickness >6 mm is required; toughness properties differ. For small vessels <6 mm and low pressure, SS-grade HSLAS might suffice—but certification oversight applies.

Q2: Which offers better weldability?

A: A1011, particularly Class 2 HSLAS, has low CEV → easier to weld. A415 needs pre/post-heat, proper control to avoid hard spots.

Q3: Are A1011 and A36 interchangeable?

A: In thin-sheet structural tasks yes—A1011 SS‑36 and A36 plate are similar in mechanical values. But A36 isn’t certified for HSLA or formability roles served by A1011.

Q4: Is there a standard spec for A415?

A: Not widely. It’s often covered under ASME/EN norms rather than ASTM—check local code (ASME VIII, EN 10028 etc.) for plate specs.

Q5: How do microalloying elements in A1011 benefit performance?

A: Nb, V, Ti refine grain, increase low-temperature toughness, strength; yet maintain formability and weldability.