ASTM A536 100-70-03 is a grade of ductile iron characterized by its high strength and wear resistance. This specification is widely used in various industries for manufacturing components that require enhanced mechanical properties.

1. Chemical Composition and Microstructure

The chemical composition of ASTM A536 100-70-03 ductile iron typically includes:

-

Carbon (C): 3.50% – 3.90%

-

Silicon (Si): 2.25% – 3.00%

-

Manganese (Mn): 0.15% – 0.35%

-

Sulfur (S): Max 0.025%

-

Phosphorus (P): Max 0.05%

-

Magnesium (Mg): 0.035% – 0.050%

The microstructure consists of Type I & Type II nodular graphite as defined in ASTM A247, embedded in a matrix of pearlite with small amounts of ferrite. This combination provides a balance between strength and ductility.

2. Mechanical and Physical Properties

The mechanical properties of ASTM A536 100-70-03 ductile iron are as follows:

-

Tensile Strength: ≥ 100,000 psi (689 MPa)

-

Yield Strength: ≥ 70,000 psi (483 MPa)

-

Elongation: ≥ 3%

-

Brinell Hardness: Average 279

-

Machinability: Approximately 75% compared to 1212 steel

These properties make it suitable for applications requiring high strength and wear resistance.

3. Heat Treatment and Hardening Response

ASTM A536 100-70-03 ductile iron can be heat-treated to enhance its hardness. For instance, oil quenching from 1600°F (885°C) can achieve a minimum hardness of Rockwell C 50 on the outer surface. The inner diameter hardness may be lower due to larger graphite nodules, not a loss of matrix hardness.

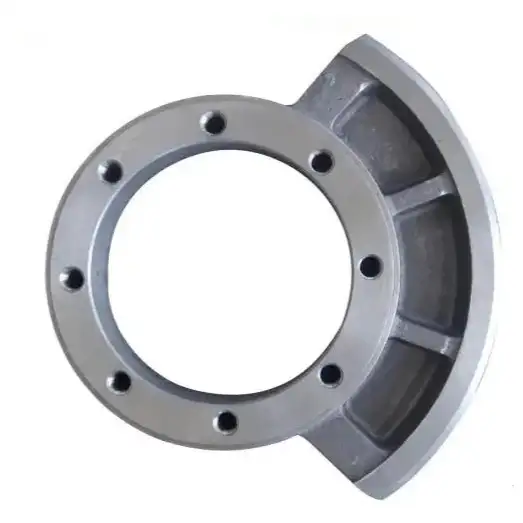

4. Applications and Industry Use Cases

Due to its high strength and wear resistance, ASTM A536 100-70-03 ductile iron is used in various applications, including:

-

Automotive Components: Engine blocks, crankshafts, and gears.

-

Industrial Machinery: Pump housings, compressor components, and gearboxes.

-

Infrastructure: Valves and fittings in water and wastewater systems.

5. Comparative Analysis with Other Ductile Iron Grades

| Grade | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Applications |

|---|---|---|---|---|

| 65-45-12 | ≥ 65,000 | ≥ 45,000 | ≥ 12 | General engineering components |

| 80-55-06 | ≥ 80,000 | ≥ 55,000 | ≥ 6 | Automotive and heavy machinery |

| 100-70-03 | ≥ 100,000 | ≥ 70,000 | ≥ 3 | High-strength applications |

| 120-90-02 | ≥ 120,000 | ≥ 90,000 | ≥ 2 | Heavy-duty industrial parts |

ASTM A536 100-70-03 offers superior strength compared to other grades, making it suitable for demanding applications.

6. Frequently Asked Questions (FAQs)

Q1: What industries commonly use ASTM A536 100-70-03 ductile iron?

ASTM A536 100-70-03 ductile iron is utilized in industries such as automotive, heavy machinery, and infrastructure. Its high strength and wear resistance make it ideal for components like engine blocks, gears, and pump housings.

Q2: How does the heat treatment process affect the properties of this ductile iron?

Heat treatment, such as oil quenching, increases the hardness of ASTM A536 100-70-03 ductile iron. This process enhances its wear resistance, making it suitable for high-stress applications.

Q3: Can ASTM A536 100-70-03 ductile iron be welded?

Welding of ASTM A536 100-70-03 ductile iron is possible but requires preheating and post-weld heat treatment to avoid cracking. Consulting welding procedures and standards is recommended.

Q4: What are the advantages of using ASTM A536 100-70-03 over other materials?

Compared to materials like gray iron or steel, ASTM A536 100-70-03 offers higher tensile and yield strengths, along with good machinability. This makes it a cost-effective choice for many applications.

Q5: Are there any environmental considerations when using this ductile iron?

ASTM A536 100-70-03 ductile iron is recyclable, contributing to sustainability. Additionally, its durability reduces the frequency of replacements, minimizing environmental impact.

Q6: How does the machinability of ASTM A536 100-70-03 compare to other materials?

With a machinability rating of approximately 75% compared to 1212 steel, ASTM A536 100-70-03 ductile iron offers good machinability, facilitating efficient manufacturing processes.