Austempering is a specialized heat treatment process applied to ferrous materials, particularly steels and cast irons, to enhance their mechanical properties. This process involves heating the material to a specific temperature to form austenite, followed by rapid cooling to a temperature above the martensite start (Ms) temperature, and then holding it at this temperature for a period sufficient to achieve the desired microstructure, typically bainite. The result is a material that exhibits improved strength, toughness, and wear resistance, making it suitable for applications where these properties are critical.

Understanding Austempering

Austempering is an isothermal heat treatment process used to produce a bainitic microstructure in ferrous materials. Unlike traditional quenching and tempering, which involves quenching the material to form martensite and then tempering to reduce brittleness, austempering eliminates the need for tempering by directly achieving a microstructure that balances hardness and toughness. This is accomplished by controlling the cooling rate and holding time after austenitization to promote the formation of bainite, a microstructure that offers superior mechanical properties.

The Austempering Process

-

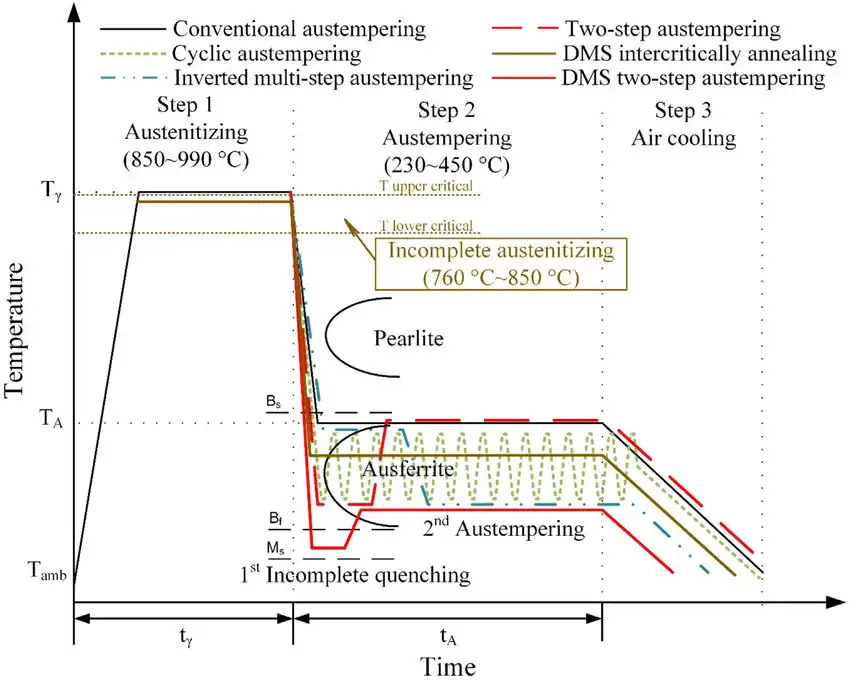

Austenitization: The material is heated to a temperature where austenite forms, typically between 790°C and 900°C, depending on the alloy composition.

-

Quenching: The material is rapidly cooled to a temperature above the Ms temperature, usually between 250°C and 400°C, to avoid the formation of martensite.

-

Holding: The material is held at this temperature for a period sufficient to allow the transformation to bainite.

-

Cooling: After the transformation is complete, the material is cooled to room temperature.

This process results in a microstructure that provides a balance between strength and toughness, making it suitable for demanding applications.

Microstructures Resulting from Austempering

The primary microstructure achieved through austempering is bainite, which can be classified into:

-

Upper Bainite: Formed at temperatures above 350°C, characterized by a plate-like structure.

-

Lower Bainite: Formed at temperatures below 350°C, characterized by a needle-like structure.

In ductile cast irons, the austempering process produces a microstructure known as ausferrite, which consists of acicular ferrite and high-carbon austenite. This structure provides a combination of high strength and ductility.

Comparison: Austempering vs. Conventional Heat Treatments

| Property | Austempering | Quench and Tempering |

|---|---|---|

| Microstructure | Bainite / Ausferrite | Martensite + Tempered Martensite |

| Strength | High | High |

| Toughness | High | Moderate |

| Wear Resistance | Excellent | Good |

| Distortion | Low | Moderate |

| Need for Tempering | No | Yes |

Austempering offers advantages over conventional heat treatments by achieving a superior balance of strength and toughness without the need for tempering, thereby reducing processing time and costs.

Applications of Austempering

Austempering is widely used in various industries for components requiring high strength, toughness, and wear resistance, including:

-

Automotive: Gears, crankshafts, suspension components.

-

Agricultural: Plowshares, harrow discs.

-

Railway: Couplers, wheels.

-

Mining: Crusher liners, excavator buckets.

-

Construction: Bulldozer blades, loader arms.

The versatility of austempering makes it suitable for a wide range of applications where performance and cost are critical considerations.

Advantages of Austempering

-

High Strength-to-Weight Ratio: Austempered materials provide high strength without the weight penalty of steel, making them ideal for weight-sensitive applications.

-

Excellent Wear Resistance: The bainitic microstructure offers superior wear resistance, extending the lifespan of components.

-

Cost-Effectiveness: Austempering is more economical to produce than forged steel, offering similar performance at a lower cost.

-

Good Machinability: Despite its high strength, austempered materials retain good machinability, facilitating complex part designs.

-

Versatility: Available in various grades, austempering can be tailored to meet specific performance requirements.

Limitations of Austempering

-

Brittleness at Low Temperatures: Austempered materials may exhibit reduced toughness at sub-zero temperatures, limiting their use in cryogenic applications.

-

Sensitivity to Heat Treatment: The mechanical properties of austempered materials are highly dependent on the heat treatment process; any deviation can lead to suboptimal performance.

-

Limited Availability of Grades: Not all foundries offer a wide range of austempered grades, potentially limiting material selection.

Future Trends in Austempering

Ongoing research aims to enhance the properties of austempered materials by exploring:

-

Alloying Additions: Incorporating elements like molybdenum and vanadium to improve strength and wear resistance.

-

Advanced Heat Treatment Techniques: Developing more precise and energy-efficient heat treatment processes.

-

Recycling and Sustainability: Implementing recycling methods to reduce environmental impact and improve sustainability.

These advancements aim to expand the applications of austempered materials and improve their performance in various industries.

Frequently Asked Questions (FAQs)

1. What is Austempering?

Austempering is a heat treatment process applied to ferrous materials, particularly steels and cast irons, to produce a bainitic microstructure. This process enhances the material’s strength, toughness, and wear resistance, making it suitable for applications where these properties are critical.

2. How does Austempering differ from Quench and Tempering?

Unlike quench and tempering, which involves quenching the material to form martensite and then tempering to reduce brittleness, austempering eliminates the need for tempering by directly achieving a microstructure that balances hardness and toughness. This is accomplished by controlling the cooling rate and holding time after austenitization to promote the formation of bainite.

3. What are the primary applications of Austempering?

Austempering is widely used in various industries for components requiring high strength, toughness, and wear resistance, including automotive, agricultural, railway, mining, and construction sectors. Components such as gears, crankshafts, plowshares, and bulldozer blades benefit from the enhanced properties provided by austempering.

4. What are the advantages of Austempering over conventional heat treatments?

Austempering offers several advantages over conventional heat treatments, including a superior balance of strength and toughness without the need for tempering, reduced processing time and costs, and improved wear resistance. These benefits make austempering an attractive option for manufacturing components that require high performance.

5. Are there any limitations to using Austempering?

While austempering offers numerous benefits, it has some limitations, such as reduced toughness at low temperatures, sensitivity to heat treatment variations, and limited availability of grades in some regions. These factors should be considered when selecting materials for specific applications.

6. What are the future trends in Austempering?

Future trends in austempering include the development of advanced heat treatment techniques, the incorporation of alloying elements to enhance material properties, and the implementation of recycling methods to improve sustainability. These advancements aim to expand the applications of austempered materials and improve their performance in various industries.

Conclusion

Austempering is a specialized heat treatment process that enhances the mechanical properties of ferrous materials by producing a bainitic microstructure.