Austempered Ductile Iron (ADI) is a high-performance cast iron alloy that undergoes a specialized heat treatment process known as austempering. This process enhances the material’s mechanical properties, making it suitable for demanding applications in automotive, industrial, and infrastructure sectors.

Microstructure of ADI

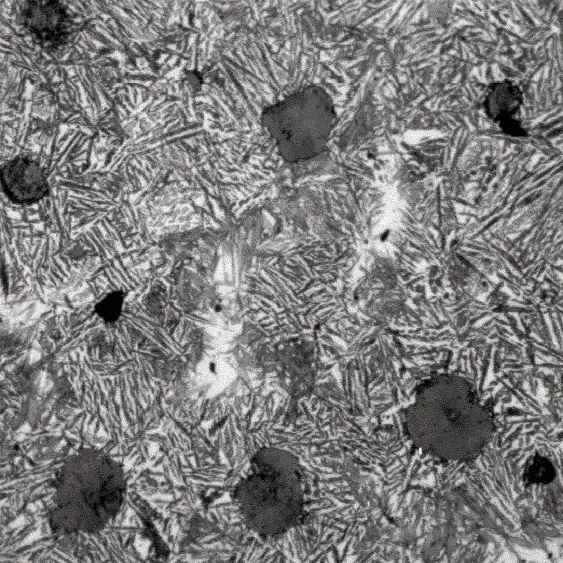

The unique properties of ADI stem from its microstructure, primarily composed of:

-

Acicular Ferrite: Provides high strength and toughness.

-

Austenite: A face-centered cubic (FCC) phase that contributes to ductility.

This combination results in a matrix known as “ausferrite,” which imparts superior mechanical characteristics compared to traditional ductile iron.

Mechanical Properties

ADI exhibits a wide range of mechanical properties, which can be tailored through the austempering process:

-

Tensile Strength: Ranges from 700 MPa to over 1500 MPa.

-

Yield Strength: Can exceed 1000 MPa.

-

Hardness: Typically between 300 to 500 HB.

-

Ductility: Elongation percentages can range from 5% to 20%, depending on the grade.

-

Impact Toughness: Charpy V-notch values can vary, with some grades achieving values above 20 J.

These properties make ADI comparable to heat-treated steels in terms of strength and toughness.

Heat Treatment Process: Austempering

Austempering involves heating ductile iron to a temperature where austenite forms, followed by rapid cooling to an intermediate temperature range (typically 260–400°C). This isothermal transformation results in the formation of ausferrite. The process parameters, such as temperature and time, are critical in determining the final properties of ADI.

Comparison with Other Materials

| Property | ADI | Cast Iron | Steel |

|---|---|---|---|

| Tensile Strength | 700–1500 MPa | 200–400 MPa | 400–2000 MPa |

| Yield Strength |

|

150–300 MPa | 250–1500 MPa |

| Hardness | 300–500 HB | 150–250 HB | 200–600 HB |

| Ductility | 5–20% | 1–3% | 10–25% |

| Wear Resistance | High | Moderate | Very High |

| Cost | Lower than steel | Lower than steel | Higher |

ADI offers a balance between strength, ductility, and cost, making it an attractive alternative to both cast iron and steel in certain applications.

Applications of ADI

ADI is utilized in various industries due to its favorable properties:

-

Automotive: Components like crankshafts, gears, and suspension parts.

-

Industrial Equipment: Machine housings, gears, and wear-resistant parts.

-

Infrastructure: Railroad wheels, brake drums, and structural components.

Its versatility allows for weight reduction without compromising performance, offering design flexibility and cost savings.

Advantages of ADI

-

High Strength-to-Weight Ratio: Provides strength comparable to steel at a lower density.

-

Enhanced Wear Resistance: Superior to traditional ductile iron.

-

Improved Fatigue Resistance: Suitable for cyclic loading applications.

-

Cost-Effective: Lower material and processing costs compared to steel.

-

Design Flexibility: Allows for complex shapes and near-net-shape casting.

Limitations of ADI

-

Sensitivity to Heat Treatment: Requires precise control during the austempering process.

-

Not Suitable for High-Temperature Applications: Performance may degrade at elevated temperatures.

-

Limited Availability: Not as widely produced as other materials.

Future Trends

Ongoing research focuses on optimizing the austempering process, developing new ADI grades with enhanced properties, and expanding its applications in emerging industries such as renewable energy and electric vehicles.

Frequently Asked Questions

1. What is the primary advantage of using ADI over traditional ductile iron?

ADI offers significantly improved mechanical properties, including higher strength, better wear resistance, and enhanced fatigue performance, due to its unique microstructure achieved through the austempering process.

2. How does the austempering process affect the properties of ductile iron?

Austempering transforms the matrix of ductile iron into ausferrite, a combination of acicular ferrite and stabilized austenite, resulting in superior mechanical properties such as increased strength and toughness.

3. Can ADI be used as a direct replacement for steel in all applications?

While ADI offers comparable strength and toughness to steel, its suitability as a replacement depends on specific application requirements, including temperature conditions, corrosion resistance, and load-bearing capacities.

4. What industries benefit the most from ADI?

Industries such as automotive, industrial machinery, and infrastructure benefit from ADI’s combination of strength, wear resistance, and cost-effectiveness, making it ideal for components like gears, crankshafts, and structural parts.

5. Are there environmental benefits to using ADI?

Yes, ADI’s lighter weight can contribute to energy savings in transportation and machinery, and its production process can be more energy-efficient compared to traditional steel manufacturing.

6. What are the challenges associated with ADI production?

The main challenges include the need for precise control during the austempering process to achieve desired properties and the limited availability of ADI compared to more commonly used materials.

Conclusion

Austempered Ductile Iron (ADI) represents a significant advancement in cast iron technology, offering a combination of high strength, wear resistance, and cost-effectiveness. Its unique properties make it a viable alternative to both cast iron and steel in various applications, providing engineers with a versatile material option for designing durable and efficient components.