The weight per meter of a 24-inch ductile iron pipe is a vital metric for infrastructure projects involving water supply, wastewater systems, or industrial pipelines. Ductile iron pipes (DIP) are prized for their durability and load-bearing capacity, but their weight directly impacts transportation costs, installation logistics, and structural design. On average, a 24-inch ductile iron pipe weighs 67–90 kg per meter (148–200 lbs per foot), depending on its pressure class (e.g., Class 50, 52, or 56), wall thickness, and external coatings.

1. Understanding the Weight of 24 Inch Ductile Iron Pipes

The weight of a ductile iron pipe is determined by several factors including the pipe’s diameter, wall thickness, material grade, and coatings. Understanding how these variables affect the overall weight is essential for engineers and construction managers when planning and estimating for large-scale infrastructure projects.

-

Why Pipe Weight Matters: The weight of a pipe determines how difficult it is to transport, how many pipes can fit in a truck or shipping container, and what kind of installation equipment is required. Additionally, knowing the weight helps estimate labor costs for lifting and positioning the pipes during installation.

-

Calculation Method: Pipe weight can be calculated by determining the volume of material that makes up the pipe and multiplying that volume by the density of ductile iron. The formula generally involves the pipe’s diameter, wall thickness, and the pipe’s length. Since ductile iron is denser than many other materials, this makes the weight substantial.

2. Factors Influencing the Weight of 24 Inch Ductile Iron Pipes

Several factors influence the weight of a 24-inch ductile iron pipe, including:

-

Pipe Diameter and Wall Thickness: The larger the diameter and the thicker the wall, the heavier the pipe will be. For example, a 24-inch pipe with a thick wall will weigh significantly more than one with a thinner wall, even if the diameter is the same.

-

Pipe Grade and Material Specifications: Pipes that meet higher strength standards (such as Grade 400 or Grade 450) tend to be thicker and heavier than those made from lower-strength materials (like Grade 350).

-

Coatings and Linings: Protective coatings (such as cement mortar or epoxy) add weight to the pipe. For example, a cement-mortar-lined pipe weighs more than a standard unlined pipe.

3. Calculating the Weight of 24 Inch Ductile Iron Pipes

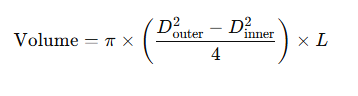

The formula for calculating the weight of a pipe is:

Weight=Density of Material×Volume of Pipe

For ductile iron pipes, the density is approximately 7,000 to 7,300 kg/m³. The volume of the pipe can be calculated using the formula for the volume of a cylinder:

Where:

-

D(outer) is the outer diameter of the pipe.

-

D(inner) is the inner diameter.

-

L is the length of the pipe (in meters).

Example Calculation:

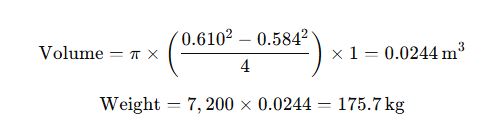

For a 24-inch pipe with a 0.5-inch wall thickness, the outer diameter is 24 inches (0.610 meters) and the inner diameter is 23 inches (0.584 meters). For a length of 1 meter, the calculation would look like this:

Thus, the weight of a 1-meter length of 24-inch ductile iron pipe is approximately 175.7 kg.

4. Different Grades and Standards of 24 Inch Ductile Iron Pipes

Ductile iron pipes come in different grades, and the grade influences both the strength and the weight of the pipe.

-

Grade 350: This is the standard grade used for most applications. It offers a balance between strength and weight. Pipes made from Grade 350 ductile iron are generally lighter compared to higher-grade pipes.

-

Grade 400: These pipes have higher tensile strength, which makes them suitable for higher pressure applications. They are typically thicker and heavier than Grade 350 pipes.

-

Grade 450: This is the strongest grade of ductile iron pipe and is used in very high-pressure applications. These pipes are the heaviest due to the additional alloying elements used to achieve greater strength.

| Grade | Tensile Strength (MPa) | Common Uses | Weight Impact |

|---|---|---|---|

| Grade 350 | 350 | General applications | Lighter |

| Grade 400 | 400 | High-pressure systems | Medium |

| Grade 450 | 450 | Very high-pressure systems | Heavier |

Coatings and linings are applied to ductile iron pipes to prevent corrosion and increase the lifespan of the pipe. These coatings add to the overall weight of the pipe.

-

External Coatings: Bituminous coatings, zinc coatings, or epoxy coatings are often applied to protect the pipe from external environmental factors such as moisture, soil chemicals, and abrasion. These coatings increase the pipe’s weight, but they also add significant protection, especially in harsh environments.

-

Internal Lining: Cement mortar linings are typically used for water distribution pipes. These linings provide additional corrosion resistance and help maintain the pipe’s integrity. However, they also add to the overall weight of the pipe.

6. Regional Price Differences and Global Trends in Ductile Iron Pipe Weight

The price of ductile iron pipes can vary based on location due to factors like local production, labor costs, tariffs, and shipping distances.

-

North America: Ductile iron pipes in North America tend to be more expensive due to stricter manufacturing standards and higher labor costs.

-

Europe: In Europe, the pipes also comply with stringent environmental and quality standards, which can drive up the price. Regional regulations and the European Union’s environmental policies contribute to the overall cost.

-

Asia: In Asia, where labor costs are lower and raw materials are often more readily available, ductile iron pipes tend to be cheaper, though shipping costs and trade tariffs can still influence pricing.

7. Why Understanding Pipe Weight is Essential for Infrastructure Projects

Knowing the weight of a 24-inch ductile iron pipe is vital for several reasons:

-

Logistical Planning: Understanding how much the pipe weighs helps with shipping calculations, the choice of installation equipment, and proper workforce planning.

-

Cost Estimation: Weight directly impacts transportation costs and labor charges for unloading and installation.

8. Frequently Asked Questions (FAQs)

Q1: What is the average weight of a 24-inch ductile iron pipe per meter?

The average weight of a 24-inch ductile iron pipe per meter typically ranges from 170 to 180 kilograms, depending on the wall thickness and coatings applied. A thicker wall will result in a heavier pipe.

Q2: How does wall thickness affect the weight of a 24-inch ductile iron pipe?

Increasing the wall thickness of a ductile iron pipe will increase its overall weight. The thicker the wall, the more material is required to construct the pipe, thus increasing the weight per meter.

Q3: Are coated 24-inch ductile iron pipes heavier than uncoated pipes?

Yes, coated pipes are heavier than uncoated pipes because the coatings, such as bituminous or epoxy, add an additional layer of material to the pipe’s surface.

Q4: Why are different grades of ductile iron pipes available?

Different grades of ductile iron pipes are available to cater to different pressure requirements and environmental conditions. Higher-grade pipes have a stronger tensile strength, but they are also thicker and heavier.

Q5: How do regional differences affect the weight and price of ductile iron pipes?

Regional differences can affect both the weight and price of ductile iron pipes due to varying manufacturing standards, labor costs, and transportation distances. Pipes from regions with lower manufacturing costs may be lighter or less expensive, but these differences are typically small.

Q6: How can I calculate the total weight of ductile iron pipes for my project?

To calculate the total weight, multiply the weight per meter of the pipe by the total length required. Don’t forget to factor in any additional weight from coatings or linings, and consider any other project-specific factors that might impact weight.